Flame arrester

a technology of arrester and flame, which is applied in the direction of boring tools, steam boiler components, combustion process, etc., can solve the problems of increased cost, increased fire or explosion, and continual burning on the emergent face of the arrester,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Description of Baseline Test--Without the Flame Arrester of the Present Invention

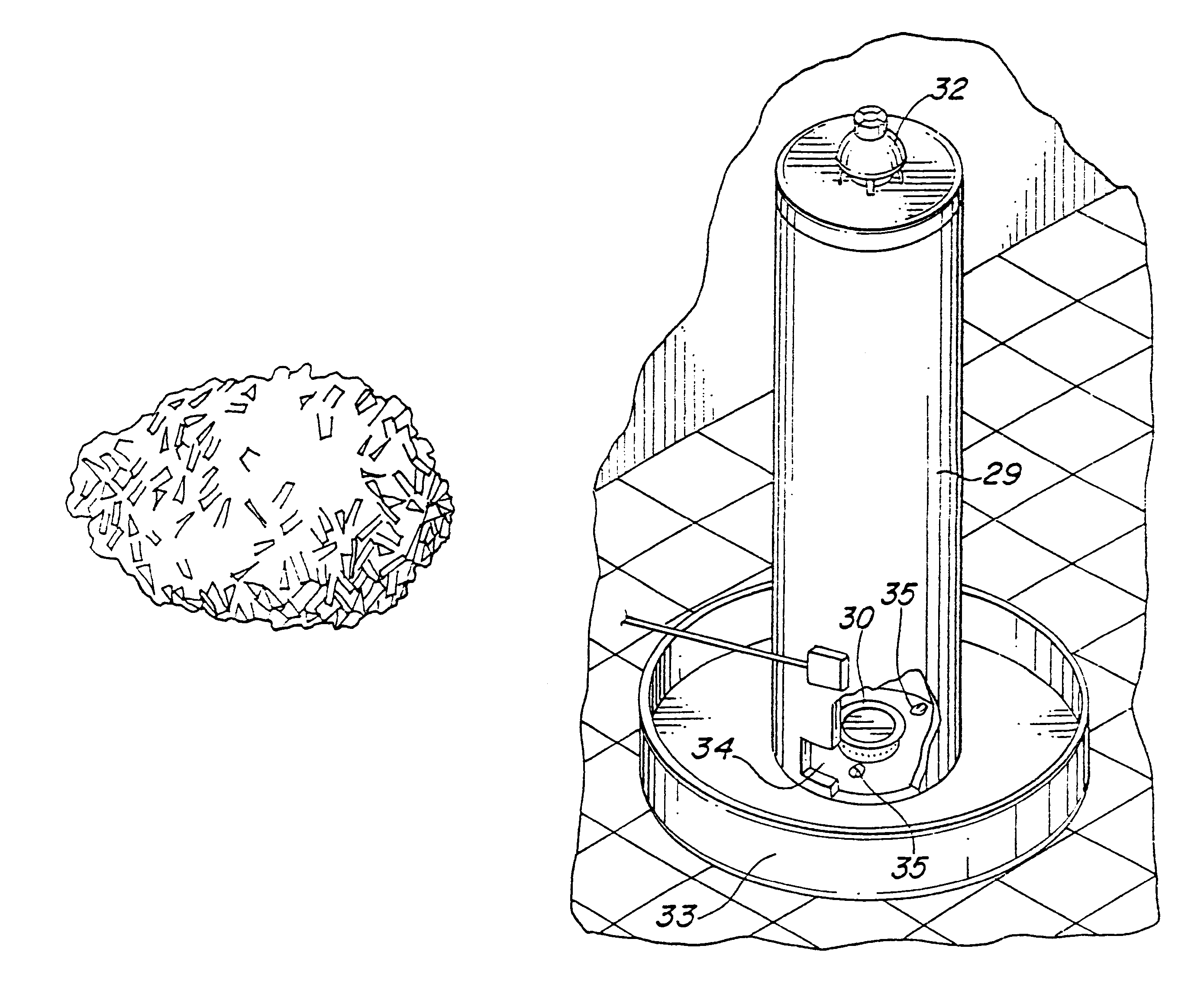

The residential water heater 29 utilized in this demonstration is shown in FIGS. 12 and 13. The heater had the following specifications:

Bottom-fired: natural gas, 33,000 Btu / hour

Standing pilot: natural gas, 1,000 Btu / hour

Burner: steel, multi-port, ring configuration

Water tank capacity: 30 gallons

Vent: central, 3-inch vertical flue

Cabinet style: "tall", 60 inches

The tank 29 included the standard components such as a main burner 30, a burner access panel 31, and a vertical flue vent 32. Positioned beneath the water heater 29 was a stainless steel moat 33, into which regular octane gasoline was poured to simulate an accidental spill. The natural gas supply line (not shown) was made of copper tubing to withstand the flames that resulted when the spill was ignited. Baseline tests consisted of exposing the as-received, water-filled, and operating water heater 29 to a deliberate gasoline spill to determine whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com