Chitosan-coated magnetic mesoporous silica core-shell structure nano-particle and preparation method and application thereof

A technology of mesoporous silica and nanoparticles, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low adsorption capacity and difficult separation of mesoporous silica, To achieve excellent adsorption performance and improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, chitosan-coated magnetic mesoporous silica core-shell nanoparticles were first prepared according to the following steps:

[0038] 1. Preparation of Fe3O4 nanoparticles by co-deposition method

[0039] Take 120mL of distilled water, add 4.80g of ferric chloride hexahydrate and 2.01g of ferrous chloride tetrahydrate after nitrogen gas for 10min, raise the temperature to 70°C, add 10mL of ammonia water with a concentration of 23g / L, stir for 30min, then add 0.85mL of oleic acid, After continuing to react for 2.5 hours, the dispersion liquid of ferric oxide nanoparticles was obtained, separated by a magnet, and the resulting product was washed with water and ethanol successively to obtain ferric oxide nanoparticles, and the ferric oxide nanoparticles were dispersed in chloroform, and the solid The content is 0.1g / mL.

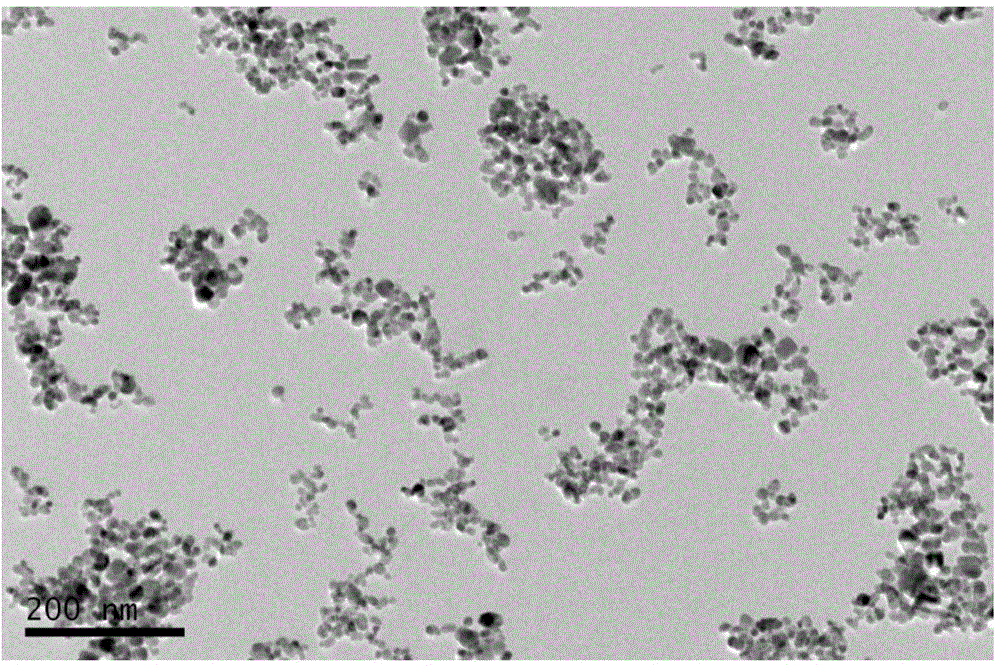

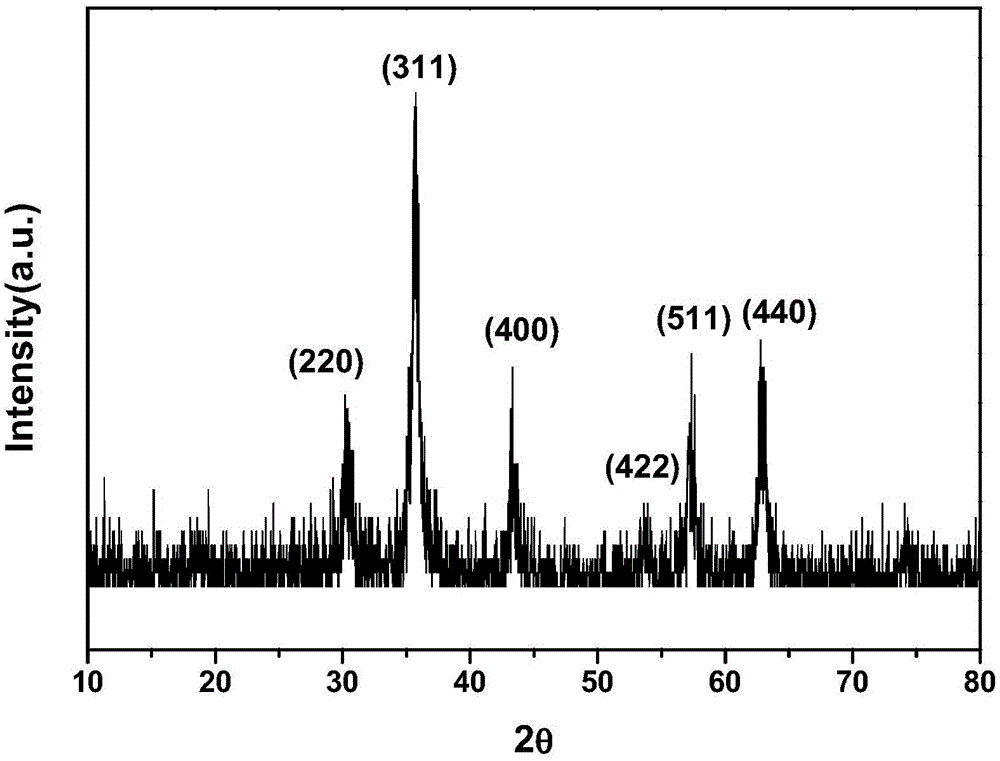

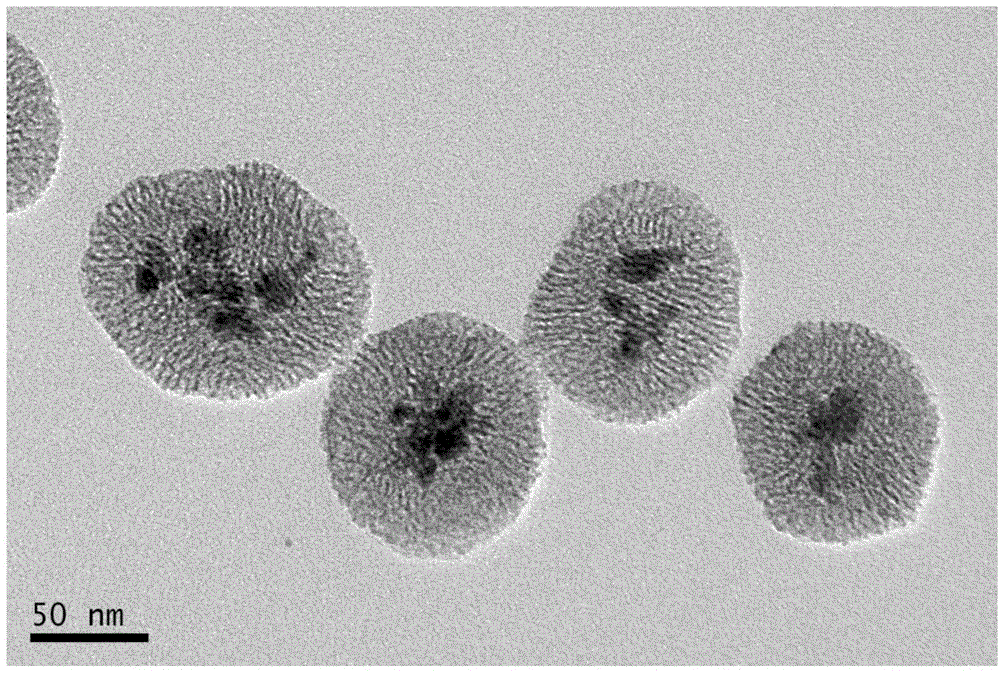

[0040] figure 1 This is the TEM image of ferric oxide nanoparticles dispersed in chloroform obtained in this example. It can be seen f...

Embodiment 2

[0059] In this example, chitosan-coated magnetic mesoporous silica core-shell nanoparticles were prepared in the same manner as in Example 1, except that the amount of iron ferric oxide nanoparticles in step 2 was 0.05 g.

[0060] After characterization, the number of ferric oxide contained in a single chitosan-coated magnetic mesoporous silica core-shell nanoparticle obtained in this example is reduced.

Embodiment 3

[0062] In this example, chitosan-coated magnetic mesoporous silica core-shell nanoparticles were prepared in the same manner as in Example 1, except that the amount of iron ferric oxide nanoparticles in step 2 was 0.15 g.

[0063] After characterization, the number of ferric oxide contained in a single chitosan-coated magnetic mesoporous silica core-shell nanoparticle obtained in this example increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com