Method for floatation-recovering valuable metals in superfine cyanided tailings by using high-cyanogen backwater

A technology for cyanidation of tailings and valuable metals, applied in flotation, process efficiency improvement, solid separation, etc., can solve the problems of inability to comprehensively recover multiple metals, increase the difficulty of element separation, and difficulty in metal recovery, etc. Achieve a win-win situation in the economic environment, increase new output value, and stabilize production indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

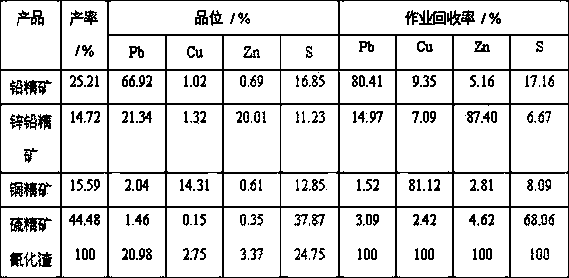

Embodiment 1

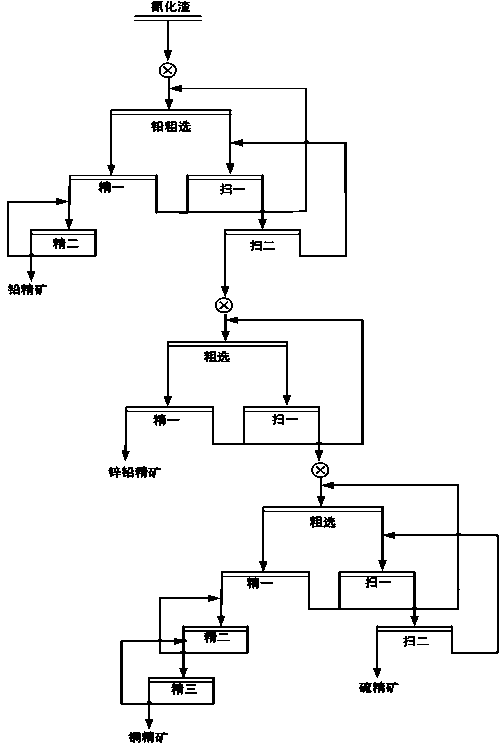

[0040] (1) Stirring and pulping: The tailings from the cyanidation gold extraction operation are concentrated by a thickener, and the underflow is fed into the slurry mixing tank, and the high-cyanide return water from the cyanidation operation is used for pulping, and the mass concentration of the pulp is controlled at 40%. After 25 minutes, the pulp is fully dispersed and then enters the lead-zinc-copper separation operation;

[0041] (2) Prioritize lead flotation: Send the pulp to the flotation unit, adjust the pH value of the pulp to 10 with lime, and recover lead by using a process of first roughing, second finishing and second sweeping;

[0042] The rough selection conditions described therein are:

[0043] Add 2 kg / t of zinc sulfate, 50 g / t of sodium hydrosulfide, 40 g / t of xanthate, 15 g / t of ethion, and 15 g / t of terpineol oil;

[0044]The primary refining conditions are: adding 500 g / t of zinc sulfate and 50 g / t of sodium hydrosulfide; the secondary refining conditi...

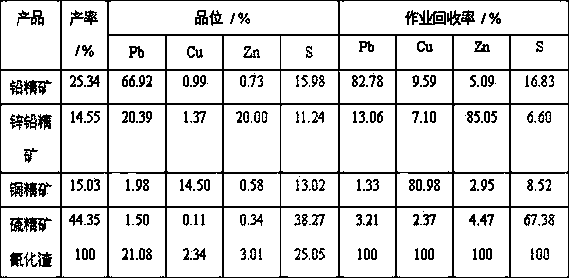

Embodiment 2

[0062] (1) Stirring and pulping: the tailings from the cyanidation gold extraction operation are concentrated by a thickener, and the underflow is fed into the slurry mixing tank, and the high-cyanide return water from the cyanide operation is used for pulping, and the mass concentration of the pulp is controlled at 38%. After 30 minutes, the pulp is fully dispersed and then enters the lead-zinc-copper separation operation;

[0063] (2) Prioritize lead flotation: Send the pulp to the flotation unit, adjust the pH value of the pulp to 10 with lime, and recover lead by using a process of first roughing, second finishing and second sweeping;

[0064] The rough selection conditions described therein are:

[0065] Add 1kg / t of zinc sulfate, 120 g / t of sodium hydrosulfide, 30g / t of butyl xanthate, 10g / t of ethion, and 20g / t of terpineol oil;

[0066] The primary refining conditions are: adding 600 g / t of zinc sulfate and 70 g / t of sodium hydrosulfide; the secondary refining conditi...

Embodiment 3

[0085] (1) Stirring and pulping: The tailings from the cyanidation gold extraction operation are concentrated by a thickener, and the underflow is fed into the slurry mixing tank, and the high-cyanide return water from the cyanide operation is used for pulping, and the mass concentration of the pulp is controlled at 45%. After 20 minutes, the pulp is fully dispersed and then enters the lead-zinc-copper separation operation;

[0086] (2) Prioritize lead flotation: send the pulp to the flotation unit, adjust the pH value of the pulp to 11 with lime, and recover lead by using the process of first roughing, second finishing and second sweeping;

[0087] The rough selection conditions described therein are:

[0088] Add 2kg / t of zinc sulfate, 10 g / t of sodium hydrosulfide, 50 g / t of fenugreek, 20 g / t of ethion, and 10 g / t of pinitol oil;

[0089] The primary refining conditions are: adding 550 g / t of zinc sulfate and 60 g / t of sodium hydrosulfide; the secondary refining conditions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com