Patents

Literature

46results about How to "Achieve liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

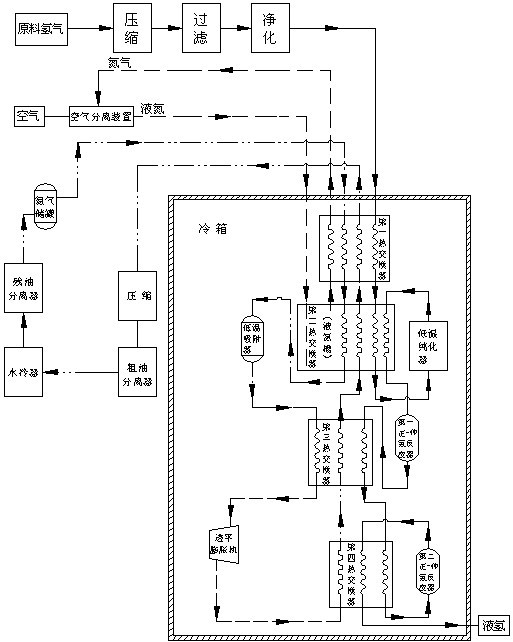

Hydrogen liquefaction process

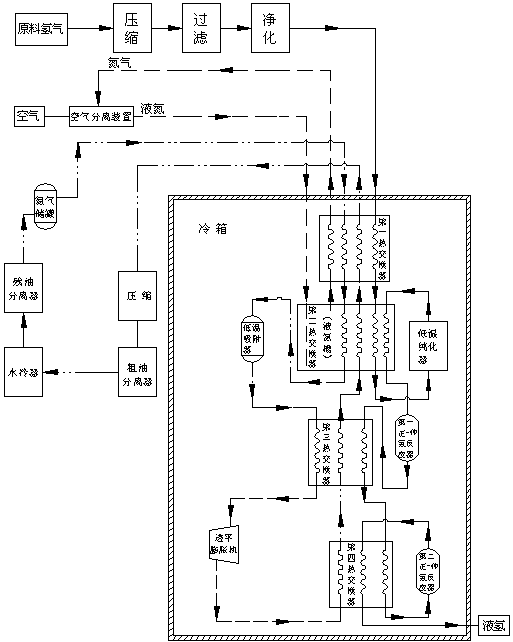

The invention discloses a hydrogen liquefaction process comprising a nitrogen refrigeration cycle, a helium refrigeration cycle and a hydrogen refrigeration cycle. In the technical scheme, liquid helium generated by a liquid helium and air separating device is used as a refrigeration working medium, refrigerating capacity required by hydrogen condensation and liquefaction is provided by the liquid helium, rewarmed helium gas and nitrogen gas are respectively recycled and can be turned into the liquid helium and liquid nitrogen after being processed correspondingly when the refrigerating capacity is provided for the hydrogen liquefaction by the liquid helium and the liquid nitrogen, thus the continuous refrigerating capacity is provided for the hydrogen refrigeration cycle by the helium refrigeration cycle and the nitrogen refrigeration cycle, waste caused by directly discharging the helium gas or the nitrogen gas is avoided, and energy sources are saved. In the intention, operation that any one of the three refrigeration cycles is independent of the other two refrigeration cycles is realized, and heat quantity exchange is carried out among the three refrigeration cycles, thus liquid hydrogen generation is finally completed, and the liquefaction of hydrogen gas is realized by sequentially utilizing the refrigerating capacity of the liquid helium and the liquid nitrogen in the hydrogen refrigeration cycle.

Owner:ALLY HI TECH CO LTD

Method for fast producing methane by utilizing excess sludge

ActiveCN103708696AShort cycleStart fastWaste based fuelBiological sludge treatmentPre treatmentEnvironmental chemistry

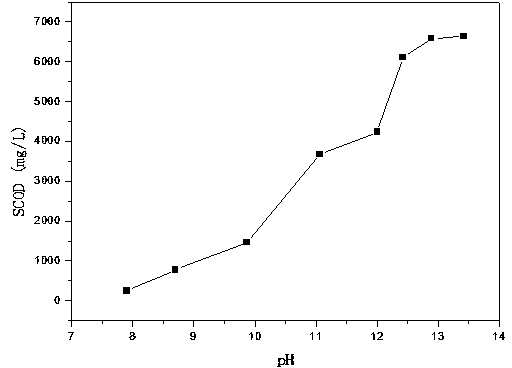

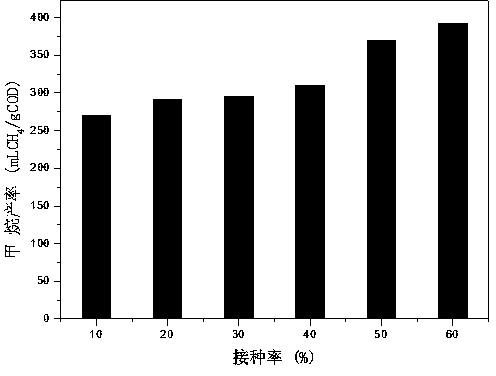

The invention discloses a method for fast producing methane by utilizing excess sludge, specifically comprising the steps of: (1) pretreating excess sludge; (2) alkaline hydrolysis: releasing organic matters in the excess sludge into a water phase through adopting a single-stage alkaline hydrolysis or a two-stage alkaline hydrolysis, wherein the SCOD (Soluble Chemical Oxygen Demand) of the water phase achieves 2000-10000mg / L. (3) production of methane through anaerobic digestion: inoculating 10%-60% by volume of anaerobic granular sludge in an anaerobic reactor, controlling the volume load at 0.30-0.75kg COD / (m<3>.d), performing methane production reaction within 72h, wherein the methane production capacity achieves 200-400mLCH4 / gCOD. The method has the advantages that the processes of firstly performing alkaline hydrolysis on the excess sludge so as to enable the organic matters to be liquidified and then performing liquid-state digestion to produce methane are fast to start, short in reaction period, stable in methane productivity, not only can energy be recovered, but also the stabilized treatment of the sludge can be realized, and remarkable and environment benefits can be both achieved.

Owner:SOUTH CHINA UNIV OF TECH

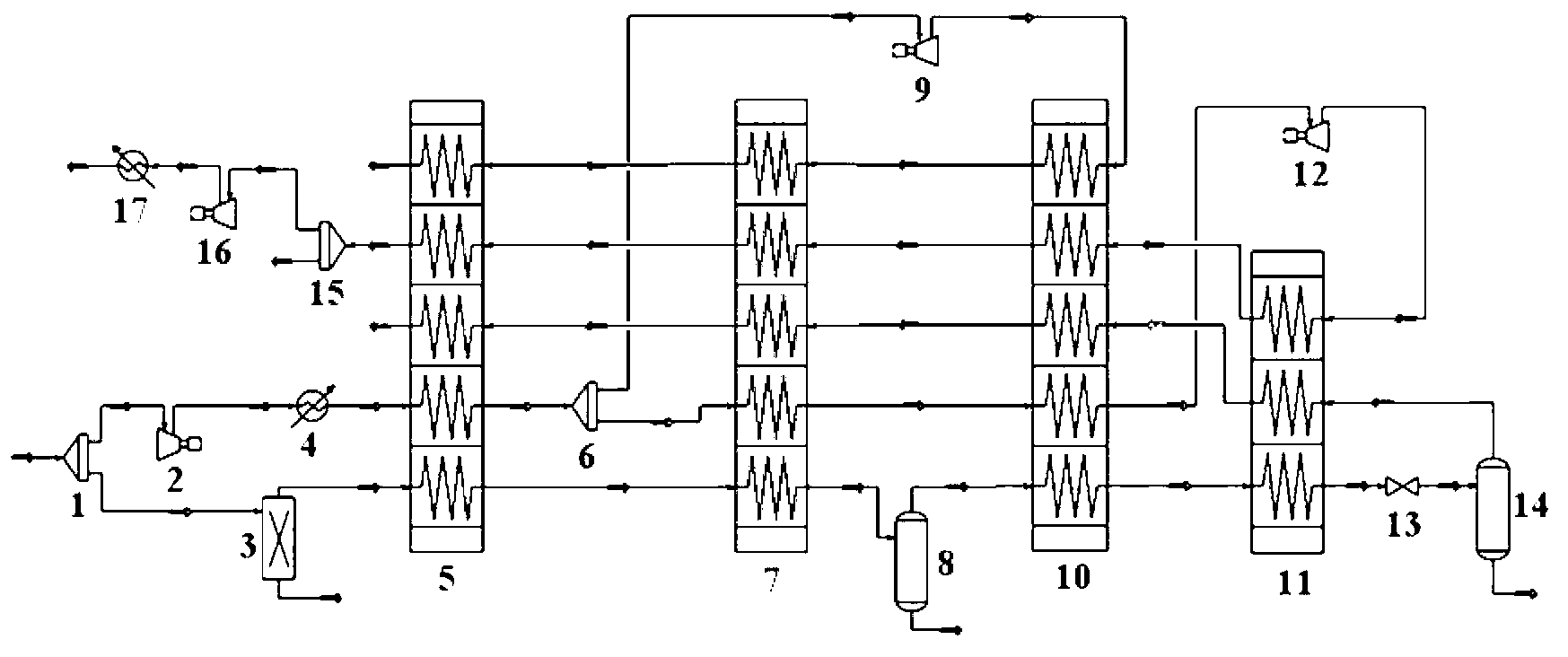

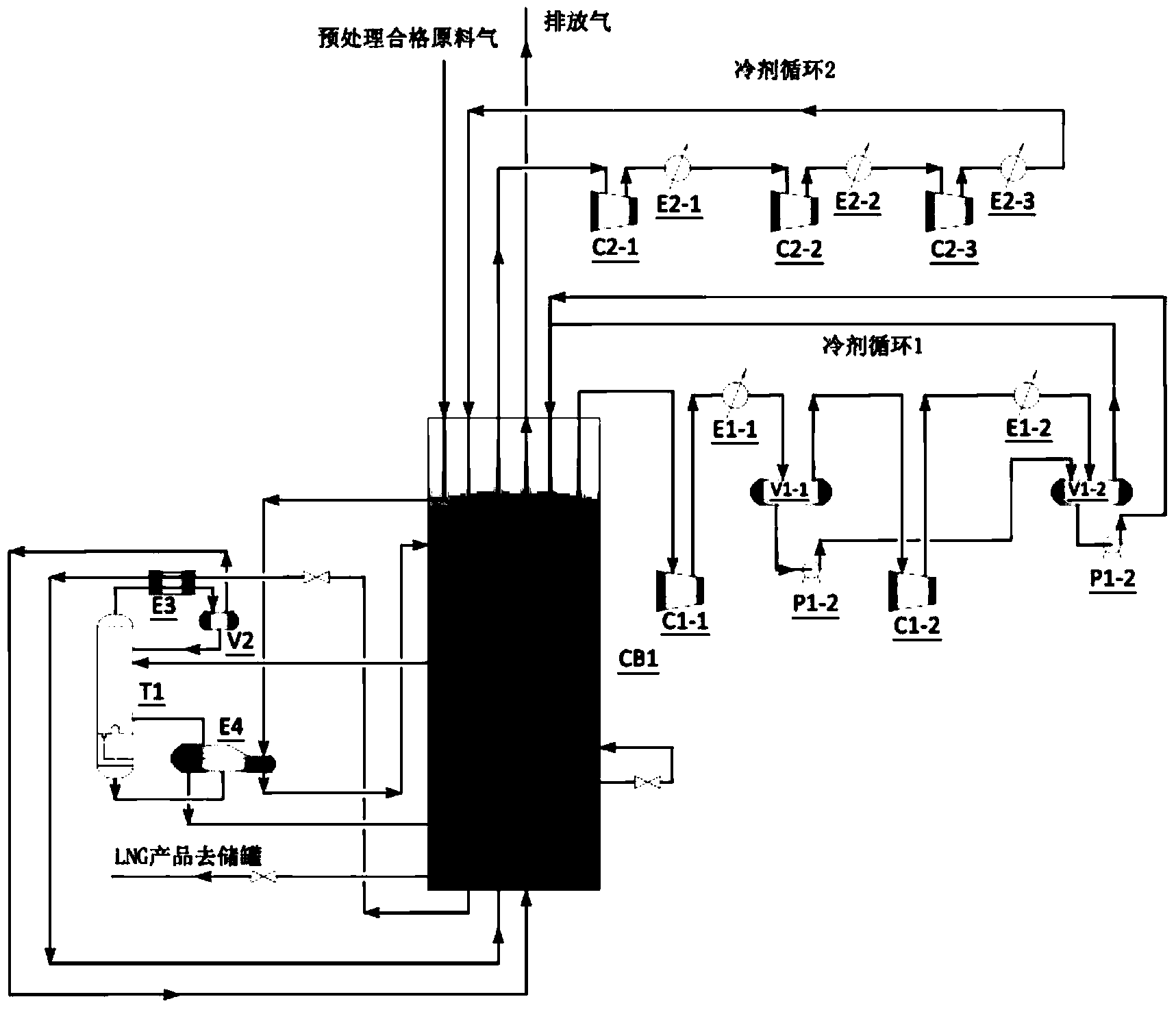

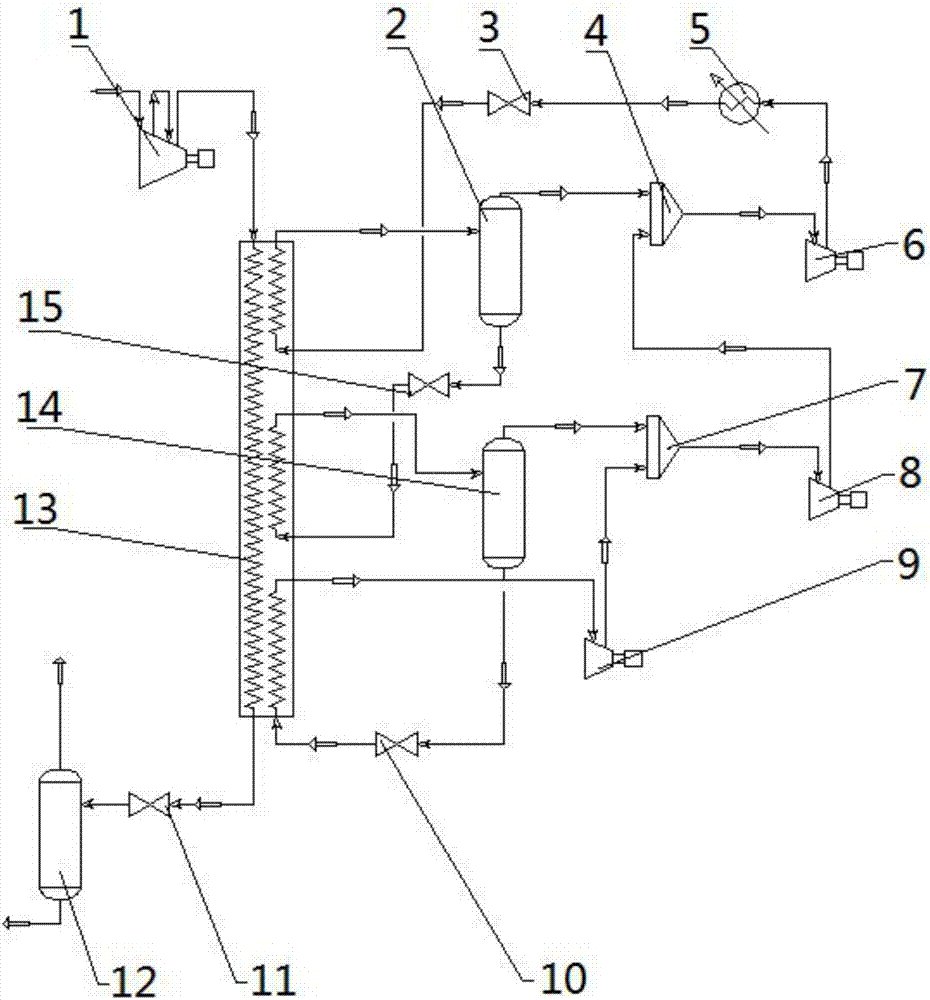

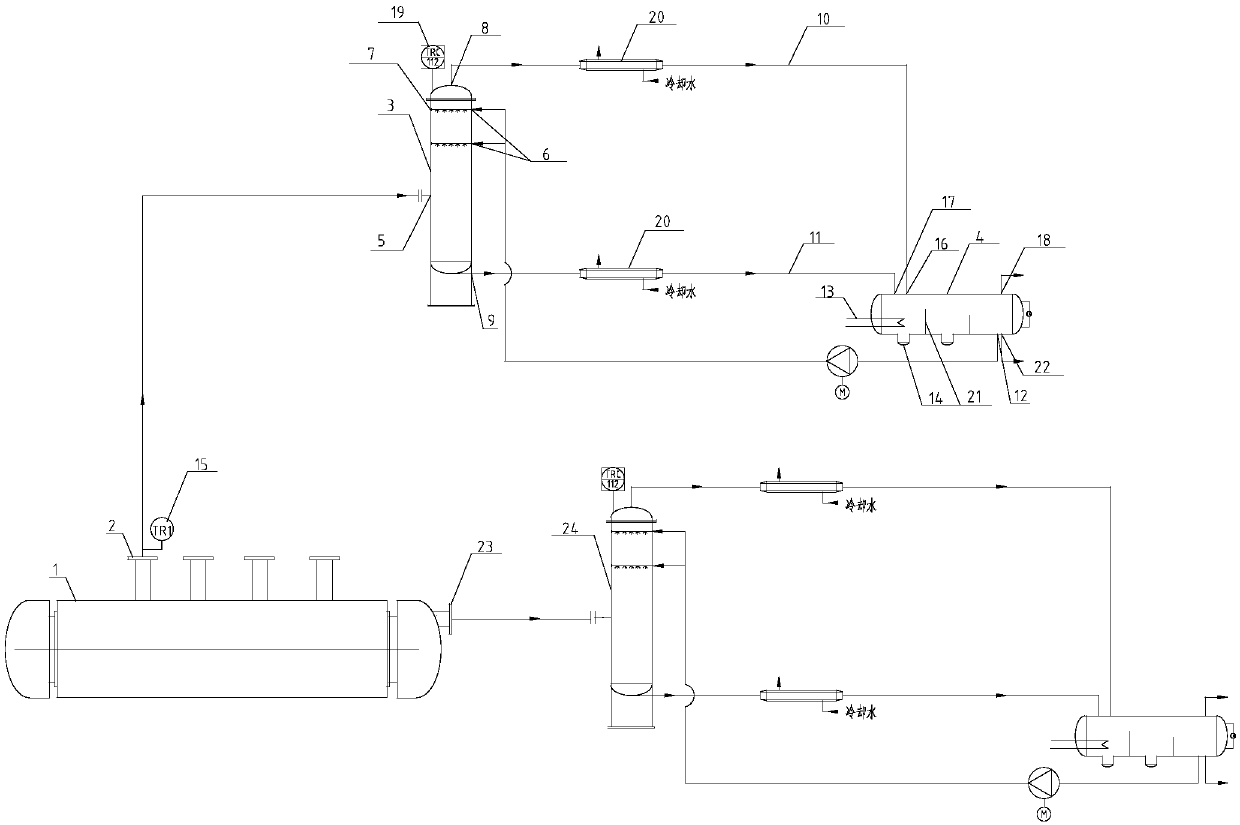

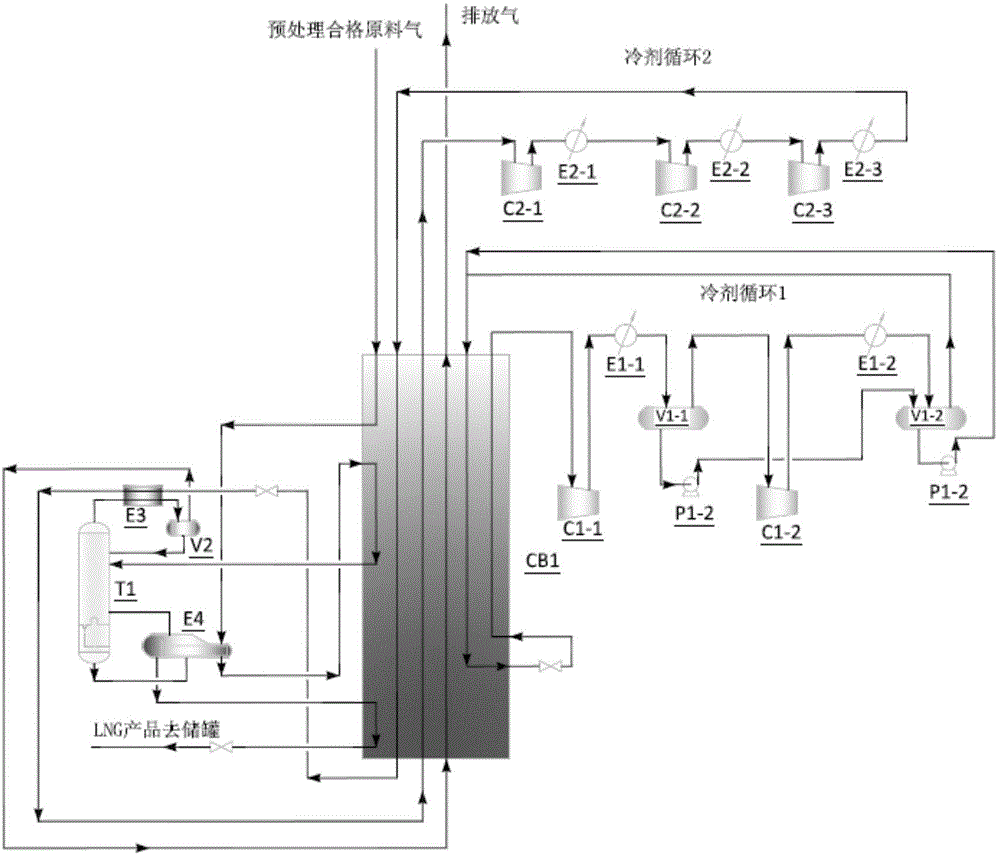

Device for preparing liquefied natural gas with pipeline pressure energy and application method thereof

ActiveCN103175379AAchieve liquefactionImprove efficiencySolidificationLiquefactionVapor–liquid separatorProcess engineering

The invention provides a device for preparing liquefied natural gas with pipeline pressure energy and an application method thereof. The device is composed of a first-level shunt, a first-level supercharger, a natural gas purifier, a first-level water cooler, a first-level heat exchanger, a second-level shunt, a second-level heat exchanger, a heavy hydrocarbon separator, a first-level expansion machine, a third-level heat exchanger, a fourth-level heat exchanger, a second-level expansion machine, a throttle valve, a gas-liquid separator, a third-level shunt, a second-level supercharger, and a second-level water cooler. The invention further relates to a method for preparing liquefied natural gas with the device. According to the method, the pressure energy of a natural gas pipeline network can be utilized, high-pressure natural gas expansion cooling is directly utilized, the liquefaction of natural gas is achieved, and energy from the outside is not needed. The technological process of liquefaction can achieve the natural gas liquefaction ratio of 10-17% through appropriate parameter regulation. By means of the method, process is simple, efficiency is high, cost is low, and application prospects are broad.

Owner:合肥万豪能源设备有限责任公司

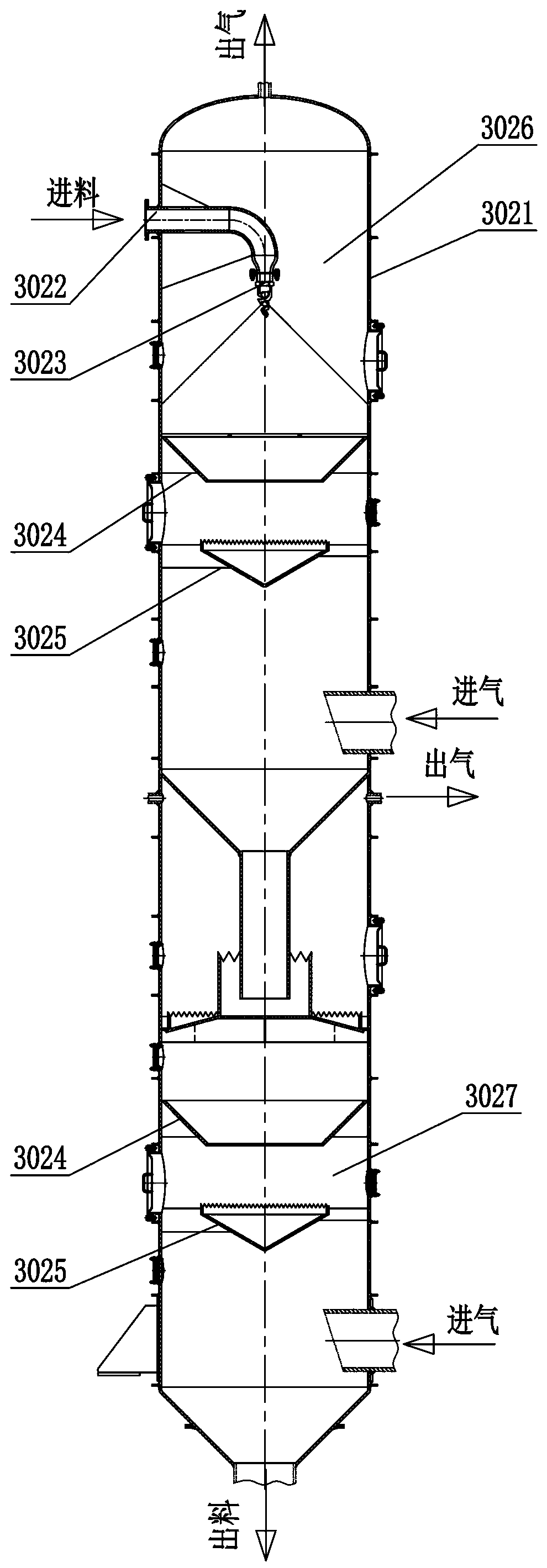

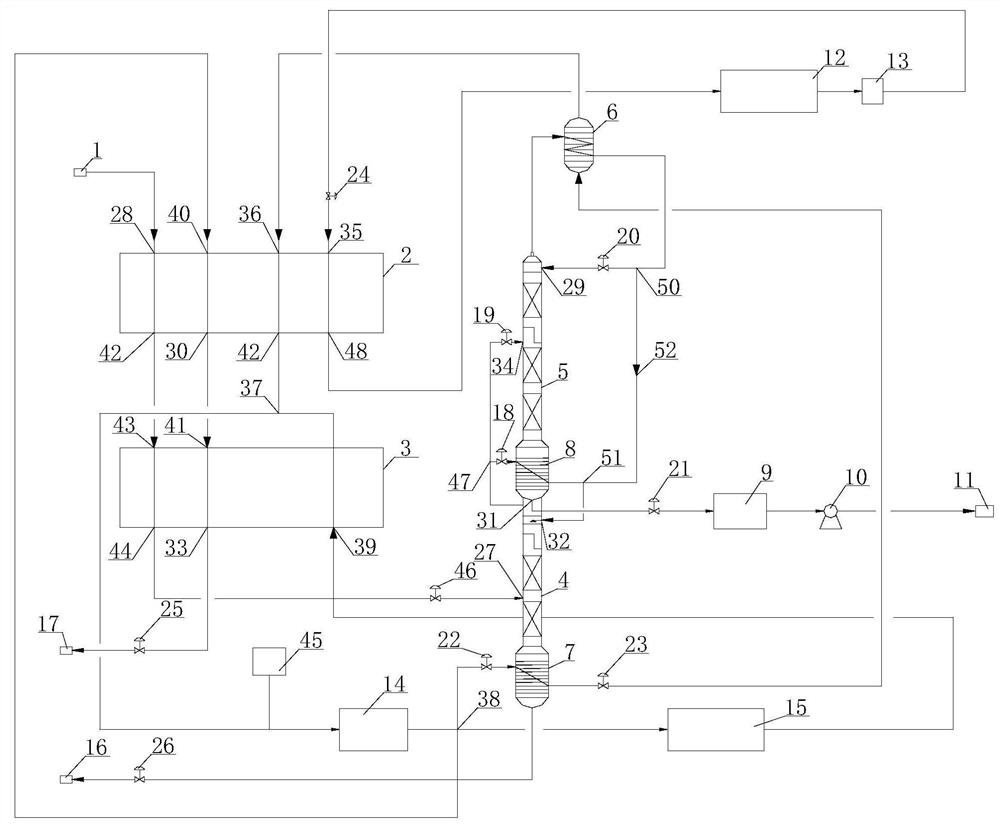

Oilfield associated gas complete liquefaction recovery system and method thereof

InactiveCN104845692ARealize separation and recoveryAchieve liquefactionGaseous fuelsResource savingEngineering

The invention discloses an oilfield associated gas complete liquefaction recovery system and a method thereof. The system comprises, sequentially connected, an associated gas pretreatment apparatus, a heat regenerator, a first condenser, a gas-liquid separation device, a throttle valve, a second condenser, an LNG storage tank and a regulating valve, the associated gas pretreatment apparatus comprises, sequentially connected, an oil removal device, a dedusting purification device, an acidic gas removal device, a hydration device and a nitrogen adsorption and separation device, the light hydrocarbon outlet of the heat regenerator is connected with the regulating valve, and the lower portion of the gas-liquid separation device is connected with the light hydrocarbon inlet of the heat regenerator. Separating recovery of light hydrocarbons in the oilfield associated gas and liquefaction of natural gas are simultaneously realized by using cold energy provided with above two stage condensing heat exchange devices. The system and the method have the advantages of solving of the recovery problem of remote region oil and gas wellhead associated gas, convenient operation, low cost, high resource recovery rate, no pollution, realization of zero discharge in the oilfield oil extraction process, and obvious resource saving and environment protection effects.

Owner:ZHEJIANG UNIV +1

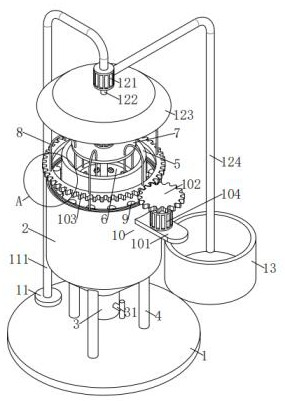

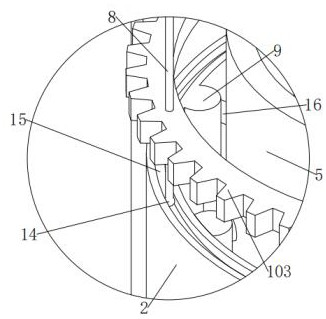

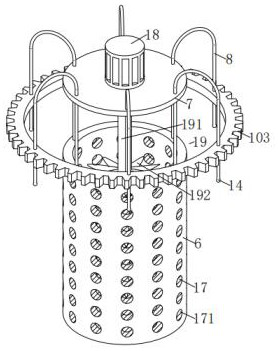

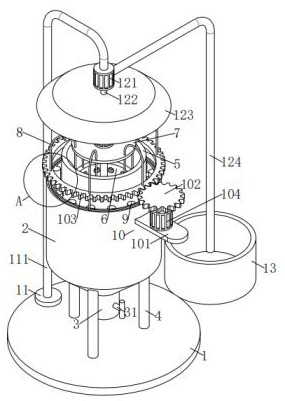

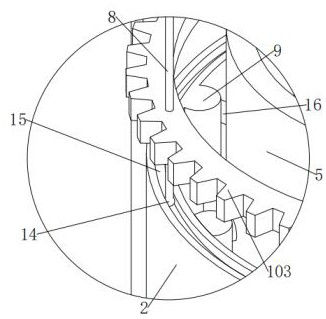

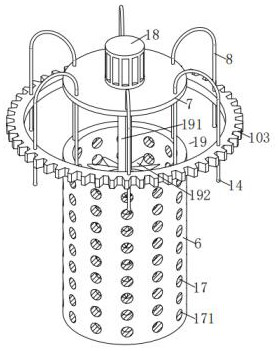

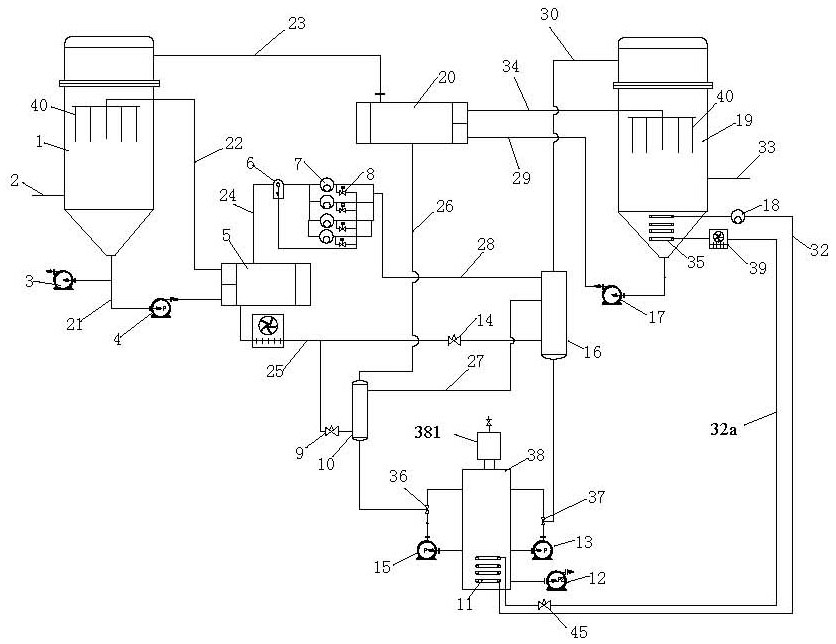

Household waste pretreatment device and pretreatment method adopting same

ActiveCN111659711AAchieve dehydrationAchieve liquefactionTransportation and packagingSolid waste disposalPretreatment methodHeat conducting

The invention discloses a household waste pretreatment device and a pretreatment method adopting same and belongs to the technical field of waste pretreatment. The household waste pretreatment devicecomprises a base, an outer cylinder arranged on the upper side of the base, a plurality of far-infrared heating pipes arranged on the inner wall of the outer cylinder in an annular array, an annular baffle plate arranged on the inner side of the outer cylinder and an inner cylinder arranged on the inner side of the annular baffle plate; the outer cylinder and the base are connected through a plurality of supporting legs for supporting; the upper part of the outer cylinder is open; the lower part of the outer cylinder is closed; a water outlet is formed in the lower part of the outer cylinder;a water discharging valve is mounted on the water outlet; the annular baffle plate is connected with the supporting legs through a plurality of groups of heat conducting connecting rods; the upper part and the lower part of the annular baffle plate are open; the upper part of the inner cylinder is open; the lower part of the inner cylinder is closed; a plurality of water draining holes are uniformly formed in the circumferential surface of the inner cylinder. The household waste pretreatment device skillfully integrates smashing, drying and solid-liquid separation and is skillful in concept.

Owner:JIANGSU HEHAI WATER SUPPLY & DRAINAGE EQUIP CO LTD

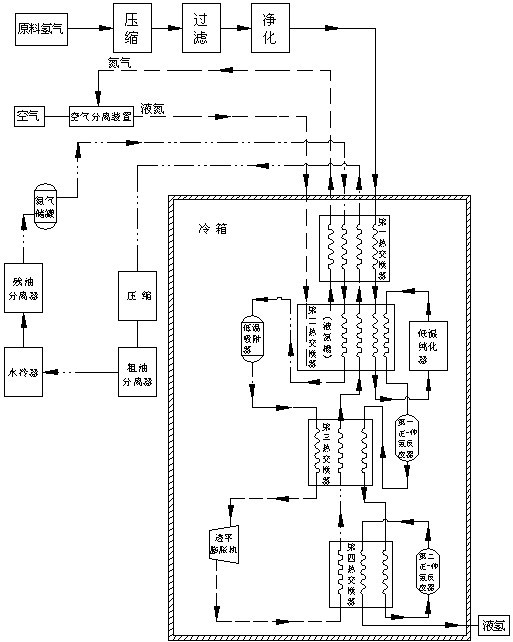

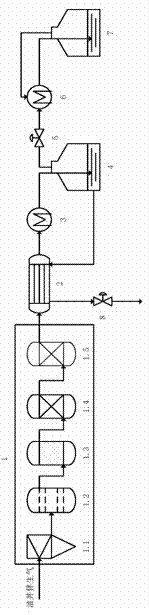

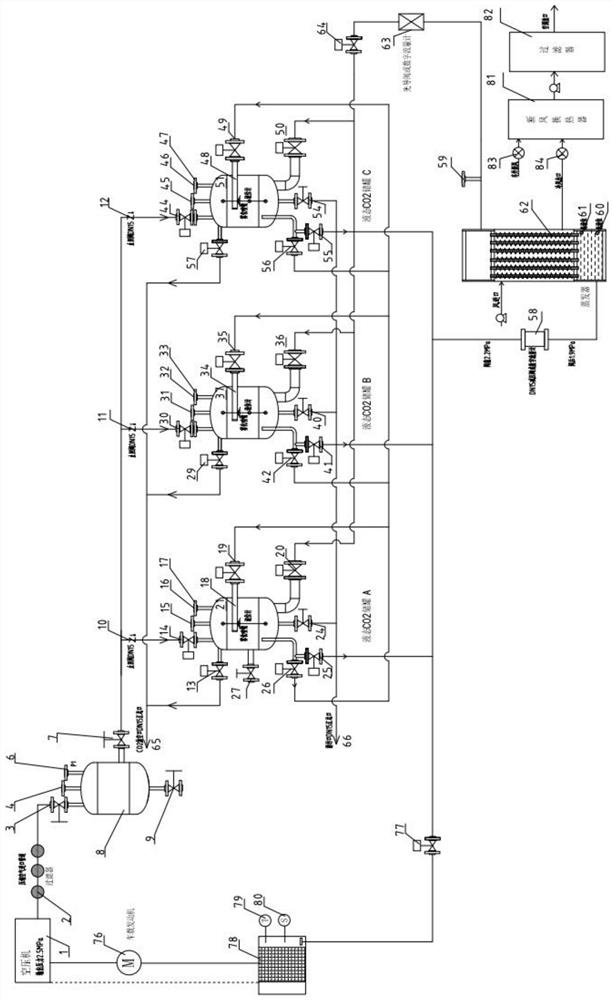

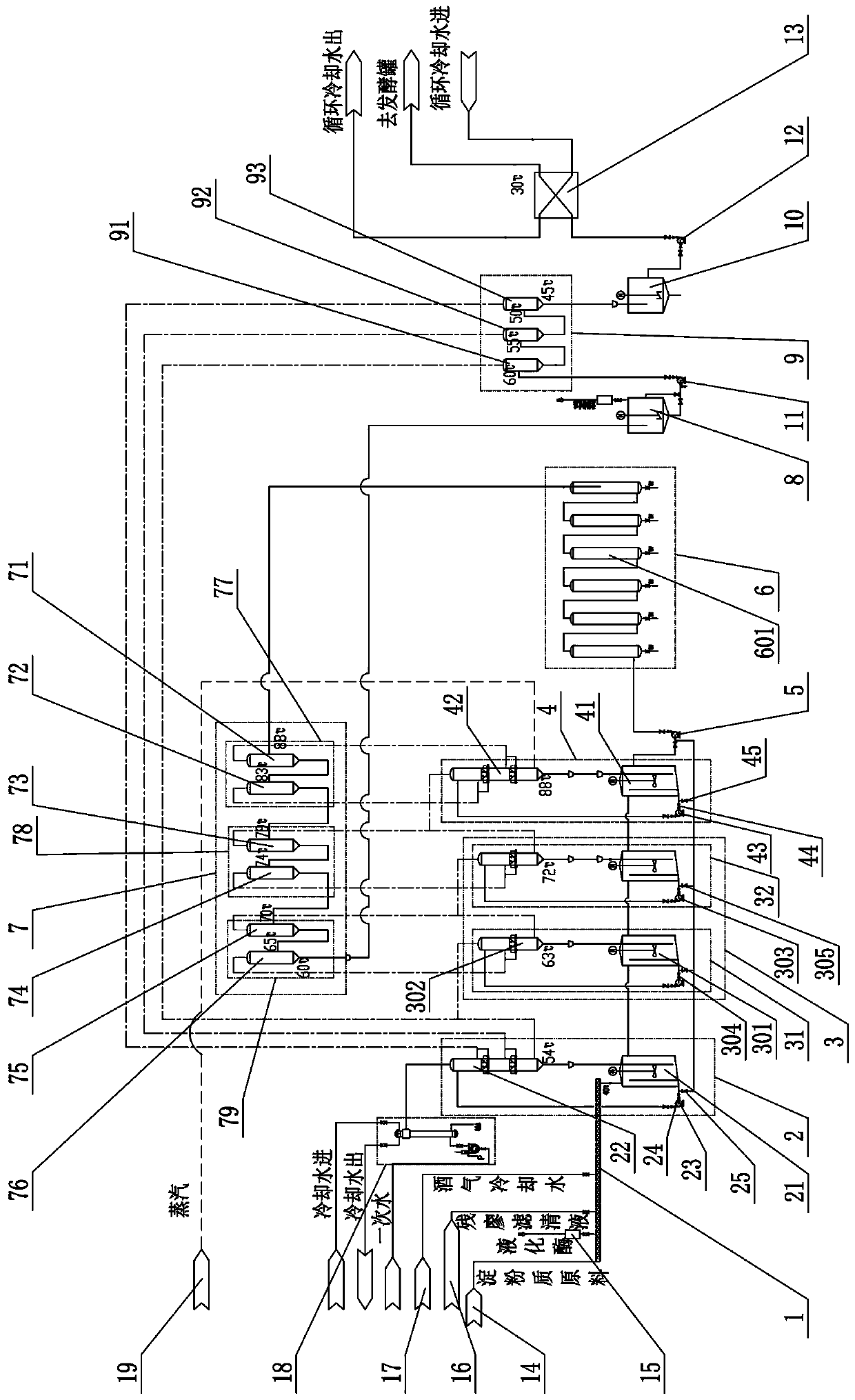

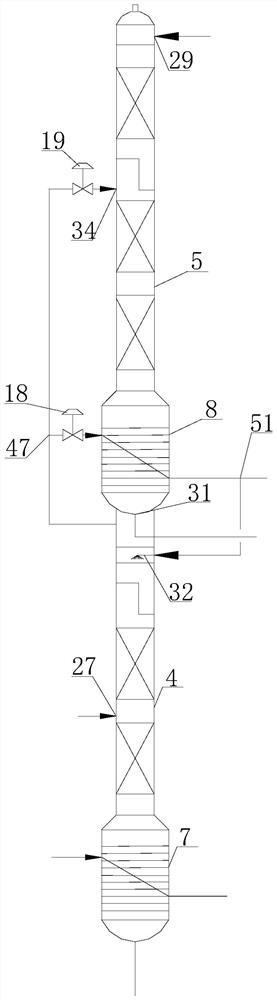

Deoxidation and denitrification system for oxygen-containing coal bed gas

The invention discloses a deoxidation and denitrification system for an oxygen-containing coal bed gas. The deoxidation and denitrification system comprises a cold box, a rectifying tower, a coal bed gas deoxidation and denitrification mechanism, a hybrid refrigerant circulation mechanism and a nitrogen refrigerant circulation mechanism, wherein the hybrid refrigerant circulation mechanism is used for supply cooling capacity for the cold box; the nitrogen refrigerant circulation mechanism is used for supply cooling capacity for the cold box and the rectifying tower; the coal bed gas deoxidation and denitrification mechanism comprises a feed gas pipeline, a after-condenser arranged on the top of the rectifying tower and a reboiler arranged at the bottom of the rectifying tower; the feed gas pipeline is communicated with the cold box, is subsequently led out from the cold box, and is communicated with the reboiler; the feed gas pipeline is led out from the reboiler, is subsequently fed into the cold box, is led out from the cold box and is communicated with the rectifying tower; a gas phase outlet of the reboiler is communicated with the cold box through a pipeline; the pipeline is cooled through the cold box and is subsequently communicated with an LNG (Liquefied Natural Gas) storage tank. Due to adoption of the deoxidation and denitrification system, a hybrid coal bed gas that the methane content of the feed gas is 30-90% can be gasified, carbon emission is reduced, and natural gas resources can be recycled to the maximum extent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

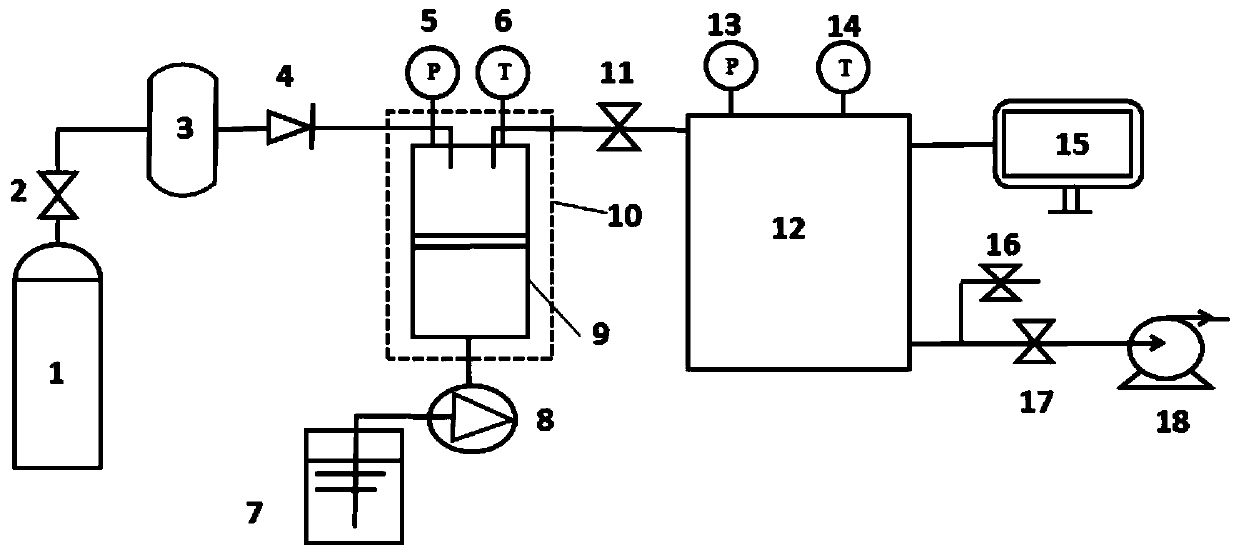

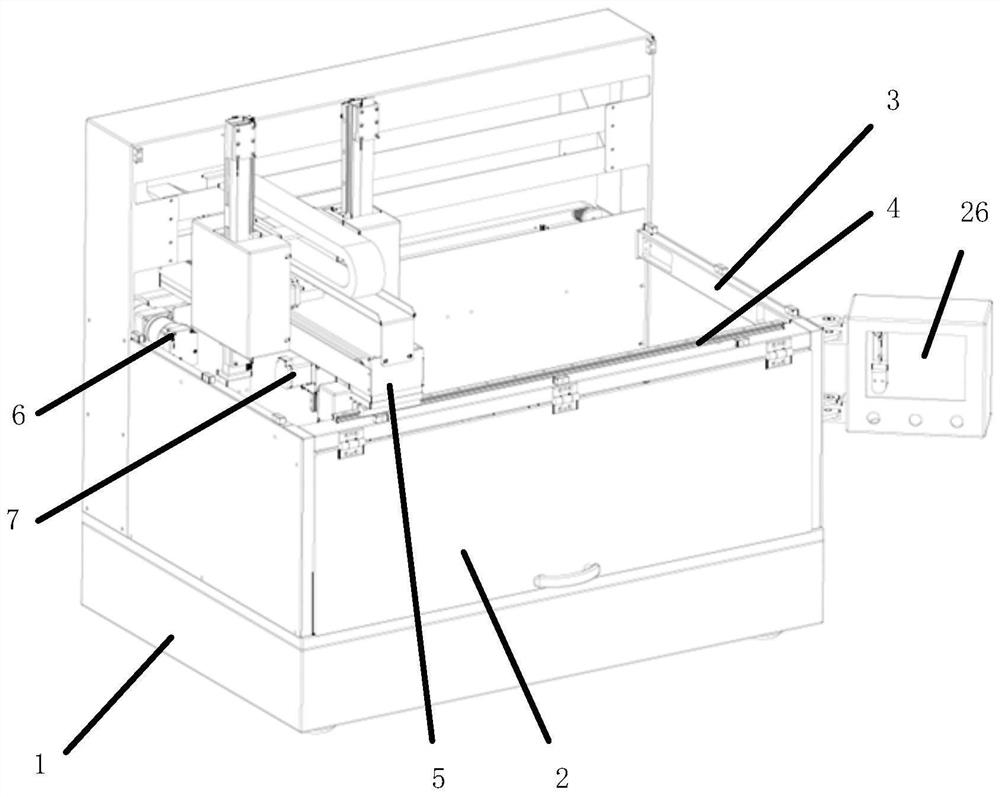

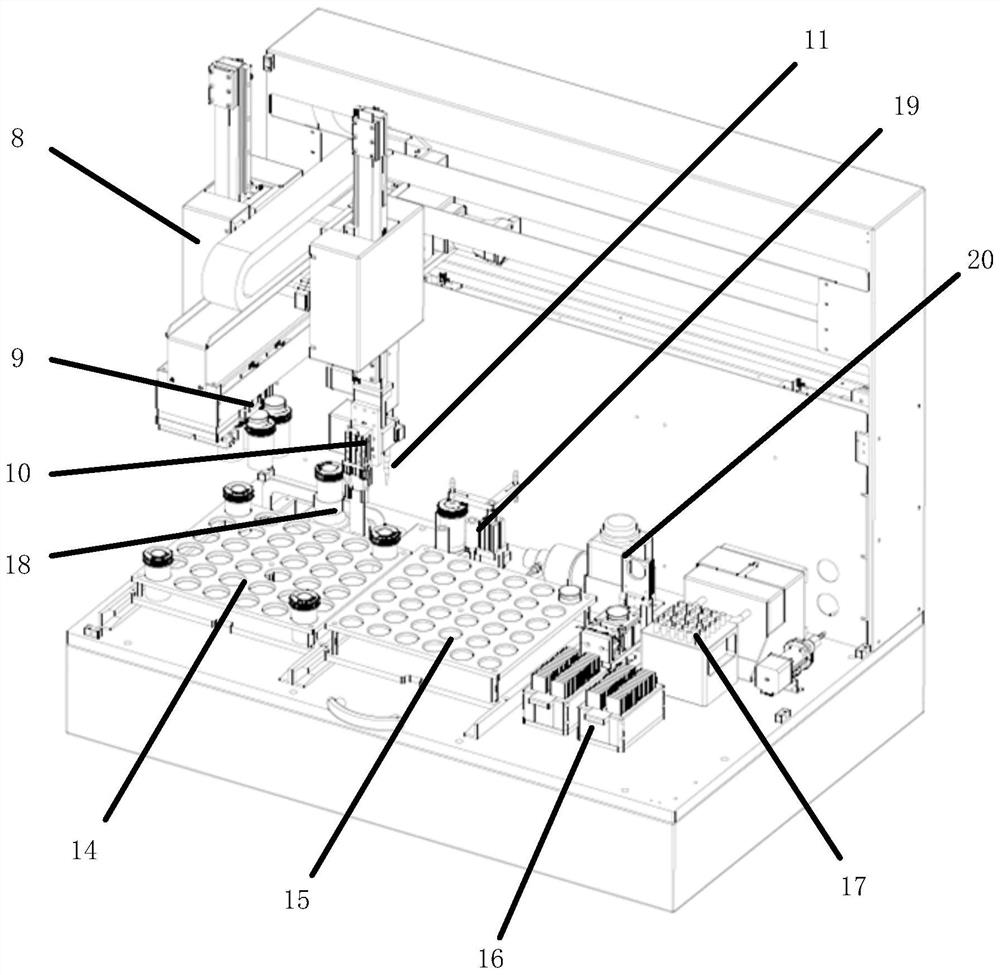

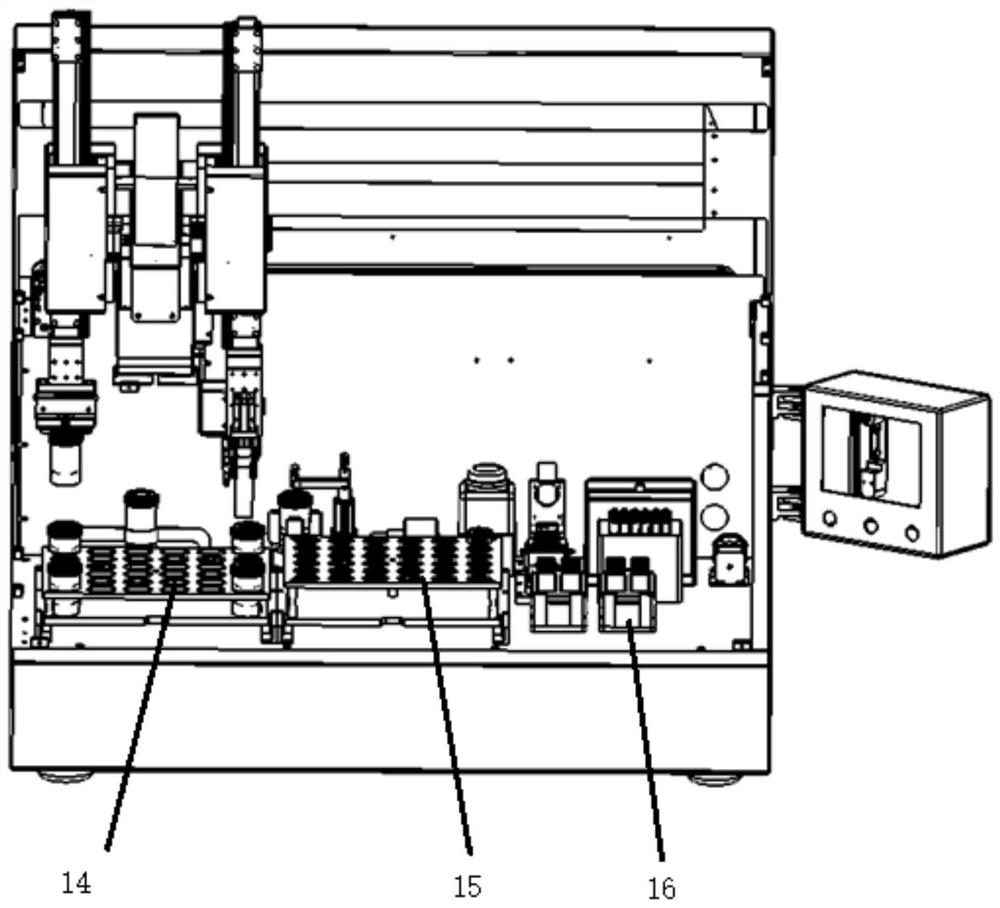

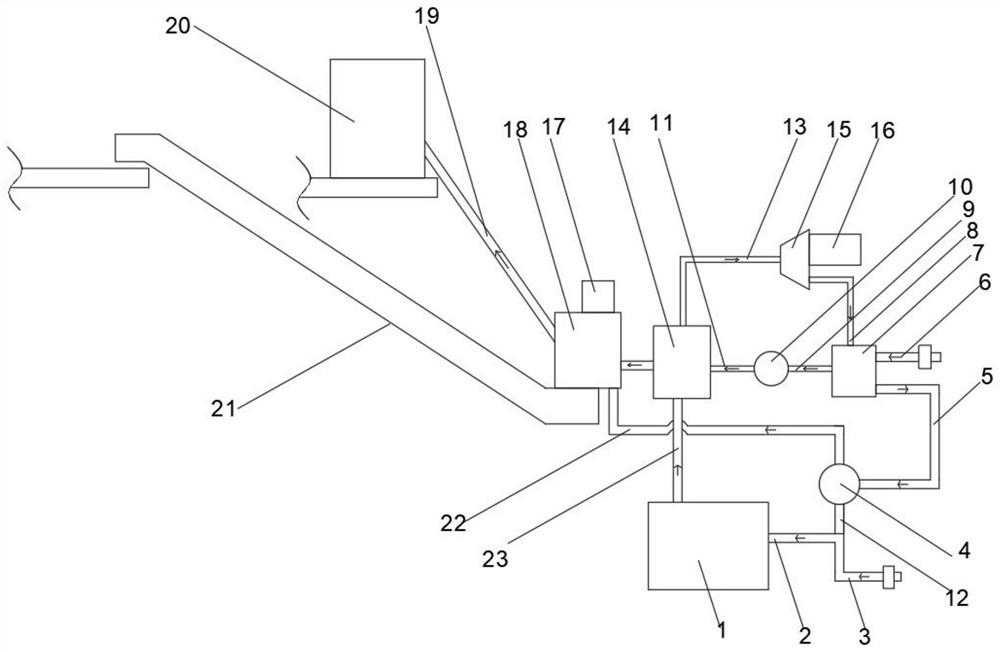

Visual CO2 anhydrous fracturing fluid rheological property test system and test method

PendingCN110715880AAvoid physical contactEliminate distractionsFlow propertiesGas cylinderFracturing fluid

The invention discloses a visual CO2 anhydrous fracturing fluid rheological property test system and test method. The system comprises a CO2 gas cylinder, a piston container and a measuring cup; an outlet of the CO2 gas cylinder is connected with an upper inlet of the piston container, and an upper outlet of the piston container is connected with an inlet of the measuring cup; and a pressure device is further arranged at the bottom of the piston container. The visual CO2 anhydrous fracturing fluid rheological property test system disclosed by the invention has a compact overall structure and simple operation, can complete the measurement work of the rheological properties of CO2 anhydrous fracturing fluid, and can directly measure rheological parameters of carbon dioxide anhydrous fracturing fluid by an experiment; and by setting different temperature and pressure conditions, and adding different types of thickeners with different concentrations, the visual CO2 anhydrous fracturing fluid rheological property test system disclosed by the invention measures the rheological properties of carbon dioxide anhydrous fracturing fluid within a relatively large range of temperature and pressure conditions. At the same time, the visual CO2 anhydrous fracturing fluid rheological property test system disclosed by the invention can accurately control the dosages of the thickener and carbon dioxide, and can observe the mixing situation of the two ingredients in a rotary rheometer in real time, and evaluate the solubility of the thickener in CO2 and the rheological properties of the CO2 anhydrous fracturing fluid by experiments.

Owner:HUANENG CLEAN ENERGY RES INST

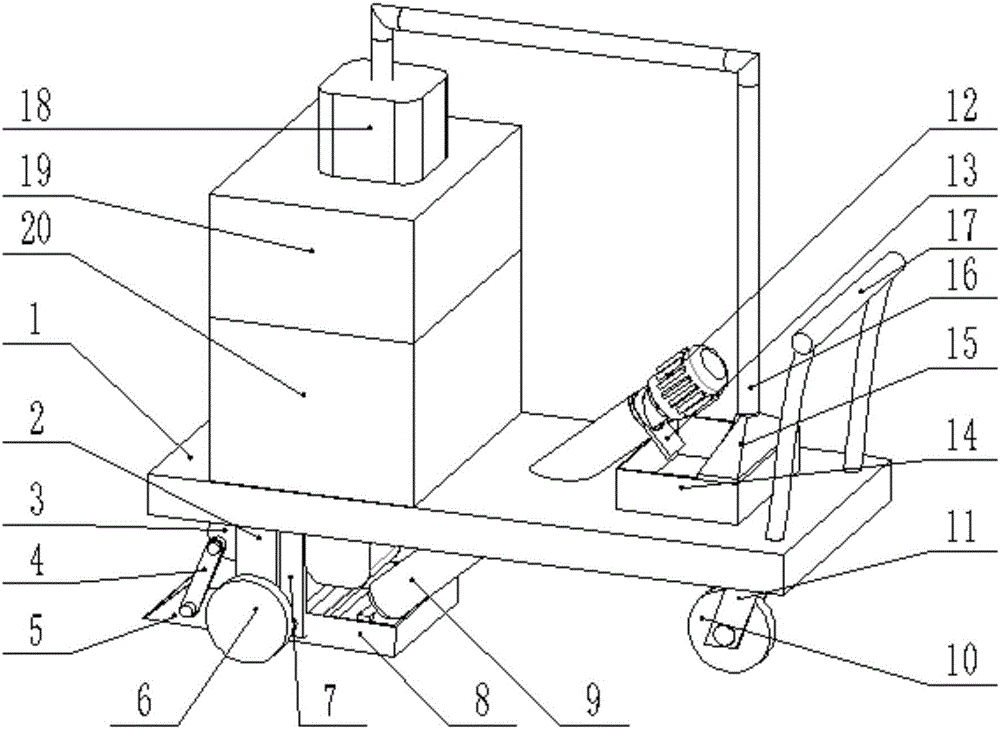

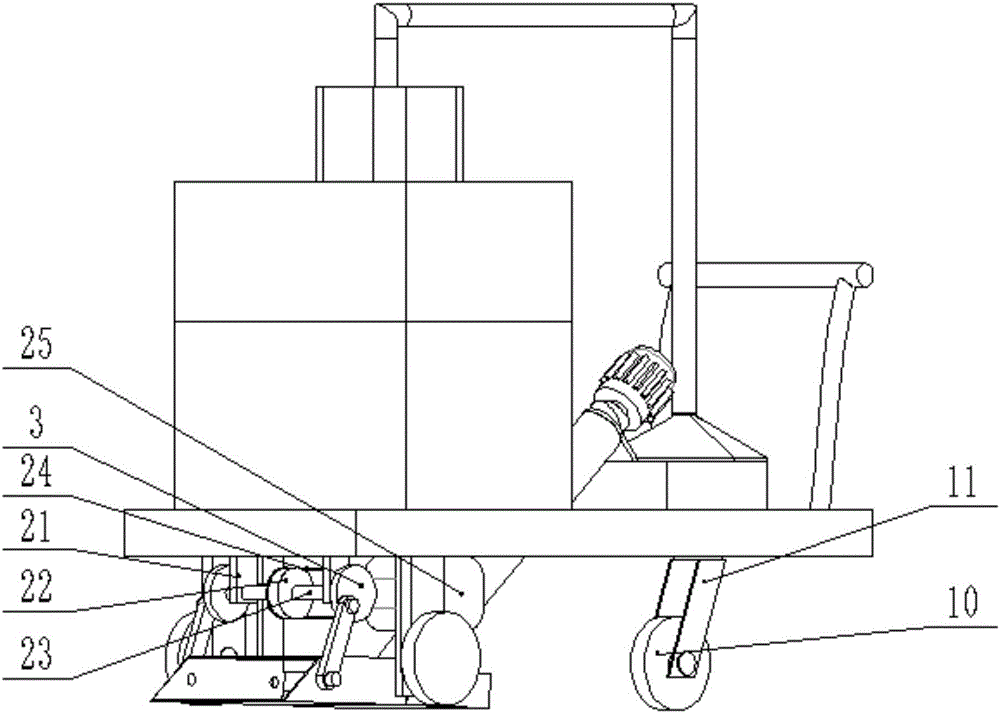

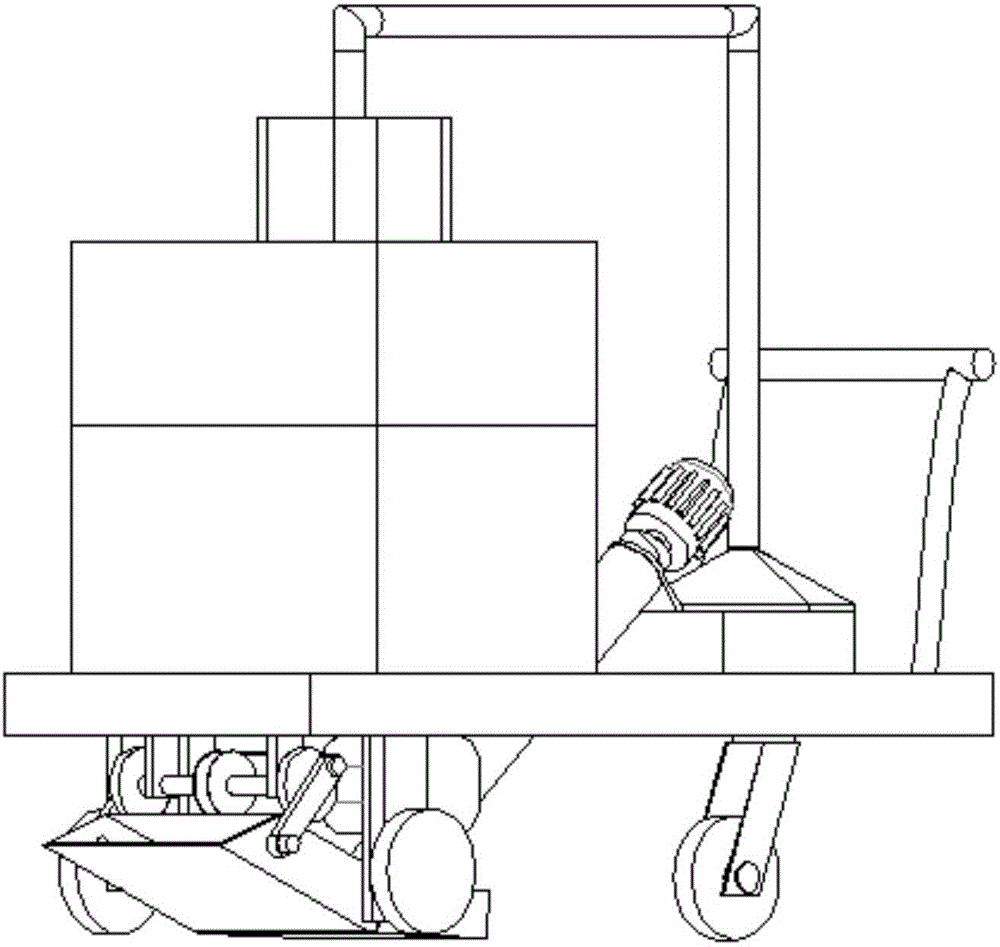

Car washing wastewater recycling and reuse device

InactiveCN106830141ASimple filterAchieve evaporative purificationTreatment involving filtrationWater/sewage treatment by heatingWastewaterPulp and paper industry

The invention discloses a car washing wastewater recycling and reuse device, and belongs to the field of sewage recycling equipment. A collecting shovel fixing plate is connected with the rear side of a collecting shovel; the front end of the collecting shovel is connected with a connecting rod; the other end of the connecting rod is fixed on a crankshaft wheel; the crankshaft wheel is fixed on a rotating shaft; a crankshaft is fixed at the lower end of a bottom plate; the rear end of the collecting shovel is connected with a containing box; the middle part of the containing box is connected with a spiral device; the other end of the spiral device is connected with a rotating motor; the spiral device is connected with a fixed end of the rotating motor and a feeding plate; a storage box is fixed on the bottom plate below the feeding plate; the other end of an air sucking hole is connected with an air inlet tube; the other end of the air inlet tube is connected with a sucking pump; the sucking pump is connected with a liquidation tank; the lower end of the liquidation tank is connected with a water containing box; the water containing box is fixed at the upper end of the bottom plate. By adopting the car washing wastewater recycling and reuse device, car washing wastewater on the ground can be collected, filtered and distilled for further use.

Owner:李彦宏

Method for rapidly extracting nutritional ingredient by grinding and liquefying enteromorpha, and preparation method of enteromorpha organic compound fertilizer

PendingCN107473816AEasy to handleImprove processing efficiencyOrganic phosphatic fertilisersOrganic fertilisersSimple Organic CompoundsDistillation

The invention relates to the technical field of rapid high-efficiency treatment and utilization and organic fertilizer production of enteromorpha, and discloses a method for rapidly extracting a nutritional ingredient by grinding and liquefying the enteromorpha, and a method for preparing an enteromorpha organic compound fertilizer by performing acid-alkali hydrolysis and concentration on the nutritional ingredient. The method for rapidly extracting the nutritional ingredient comprises the steps of soaking salvaged fresh enteromorpha with fresh water, performing salt and sand removal, performing crushing, performing mechanical grinding, liquefying the enteromorpha, extracting the nutritional ingredient of the enteromorpha, preparing enteromorpha slurry, and performing distillation and concentration in the presence of acid or alkali to obtain the concentrated and hydrolyzed enteromorpha slurry. The method for preparing the enteromorpha organic compound fertilizer comprises the steps of phosphorylating the obtained enteromorpha slurry by a phosphorylating agent, and compounding an inorganic fertilizer to prepare the organic compound fertilizer. A treatment method of the enteromorpha avoids a difficult drying technology, is low in investment, low in cost, high in efficiency and high in capacity, well meets disastrous eruptive enteromorpha environment protection treatment, and eliminates great pollution of large-scale eruptive enteromorpha to an environment.

Owner:RIZHAO XURI COMPOSITE MATERIALS

Hydrogen liquefaction process

The invention discloses a hydrogen liquefaction process comprising a nitrogen refrigeration cycle, a helium refrigeration cycle and a hydrogen refrigeration cycle. In the technical scheme, liquid helium generated by a liquid helium and air separating device is used as a refrigeration working medium, refrigerating capacity required by hydrogen condensation and liquefaction is provided by the liquid helium, rewarmed helium gas and nitrogen gas are respectively recycled and can be turned into the liquid helium and liquid nitrogen after being processed correspondingly when the refrigerating capacity is provided for the hydrogen liquefaction by the liquid helium and the liquid nitrogen, thus the continuous refrigerating capacity is provided for the hydrogen refrigeration cycle by the helium refrigeration cycle and the nitrogen refrigeration cycle, waste caused by directly discharging the helium gas or the nitrogen gas is avoided, and energy sources are saved. In the intention, operation that any one of the three refrigeration cycles is independent of the other two refrigeration cycles is realized, and heat quantity exchange is carried out among the three refrigeration cycles, thus liquid hydrogen generation is finally completed, and the liquefaction of hydrogen gas is realized by sequentially utilizing the refrigerating capacity of the liquid helium and the liquid nitrogen in the hydrogen refrigeration cycle.

Owner:ALLY HI TECH CO LTD

Liquid-based flaking method

ActiveCN109030151AFully automaticWithout human interventionPreparing sample for investigationEngineeringDigestion

The invention provides a liquid-based flaking method. The method comprises the following steps: sputum cup processing, that is, a sample liquid in a sputum cup is processed to obtain a pre-processed liquid; filtering cup operation, that is, the pre-processed liquid is filtered in the filtering cup to obtain a flaking liquid; and glass slide operation, that is, a glass slide is in contact with thefiltering cup containing the flaking liquid for transfer printing, so that a liquid-based flake is obtained. The method provided by the invention has the advantages that the whole flaking process is fully automatic and avoids manual intervention; and all samples can be automatically added with a digestion liquid and a buffer liquid, so as to be liquidized.

Owner:上海皓信生物科技有限公司

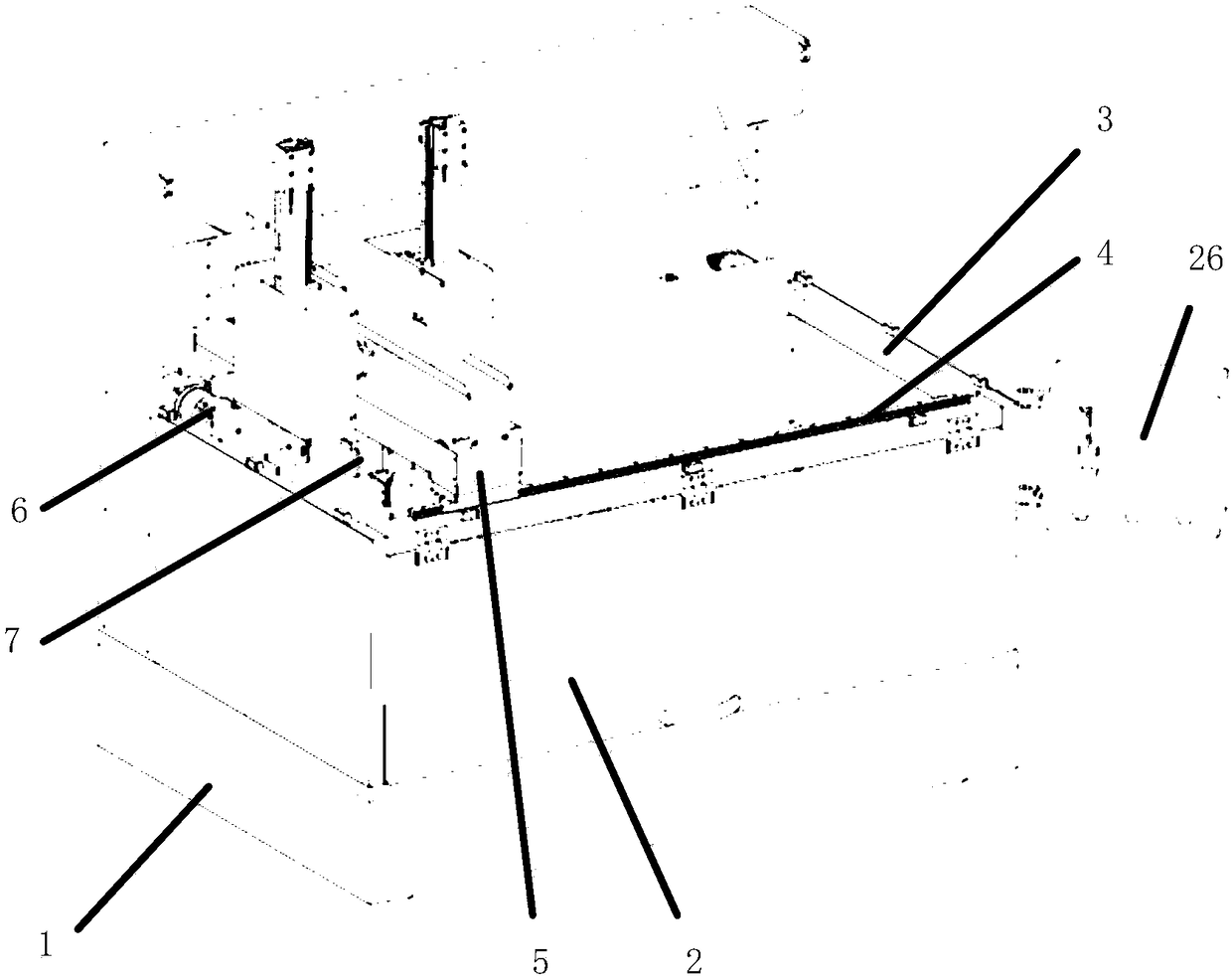

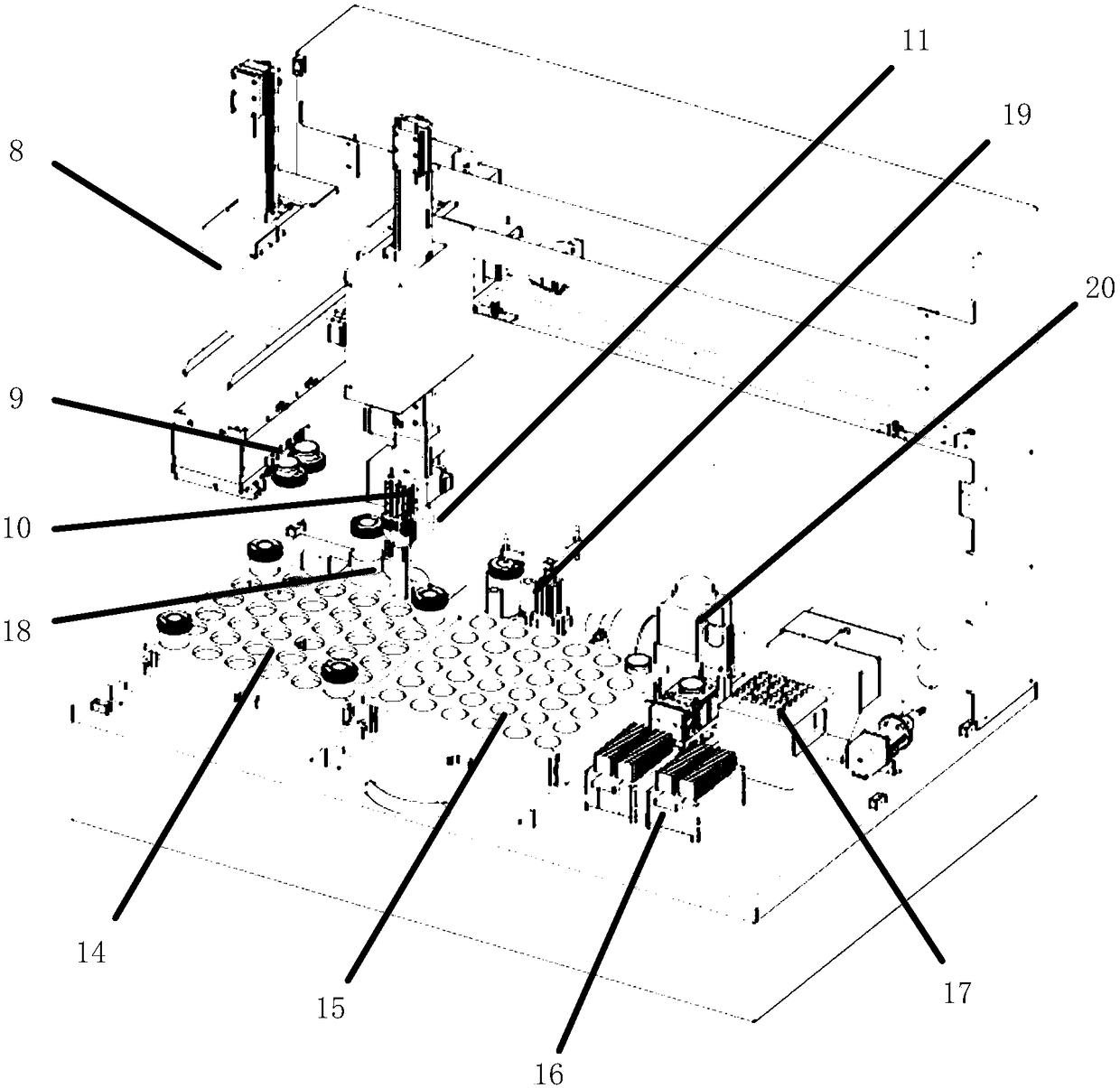

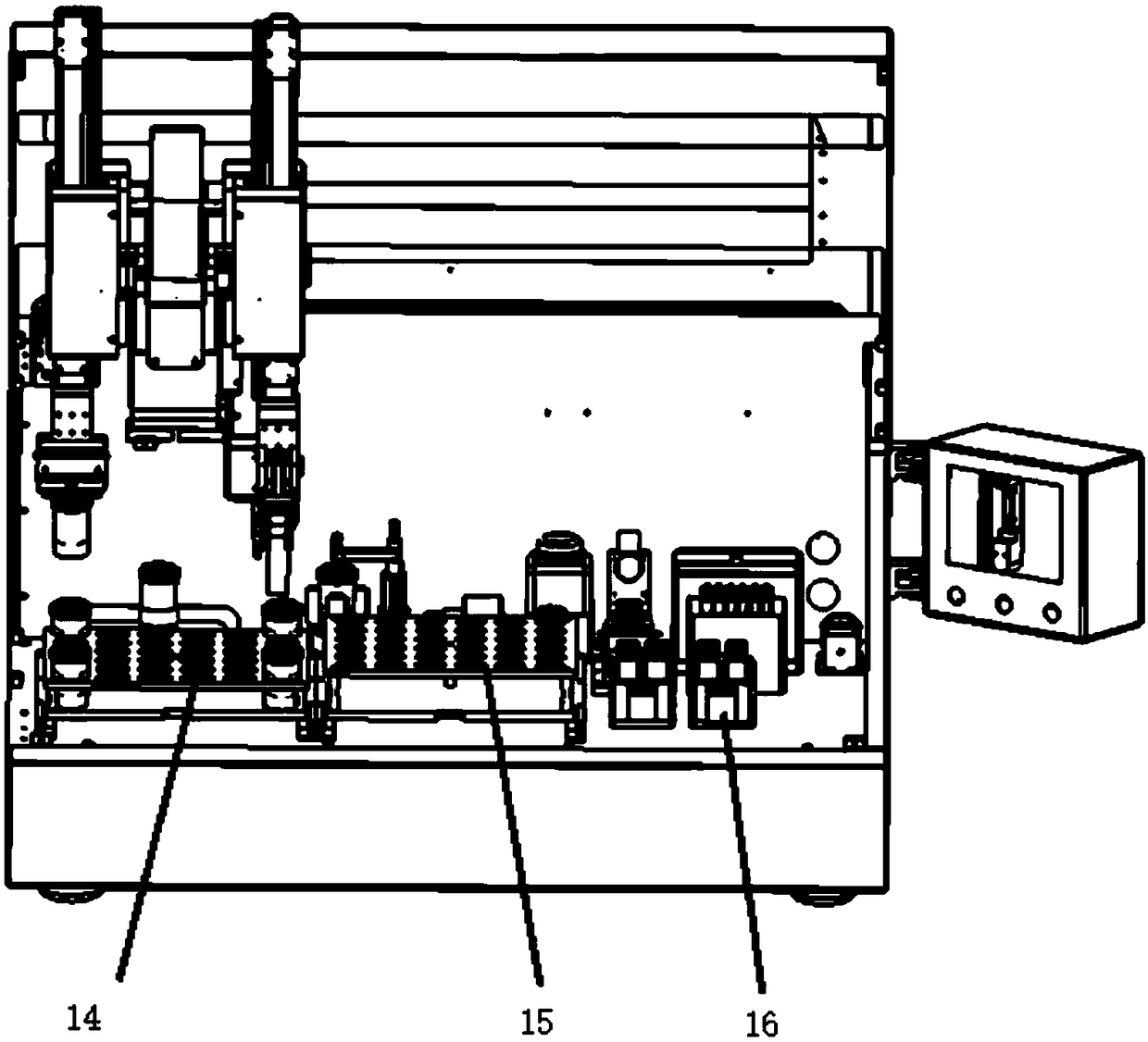

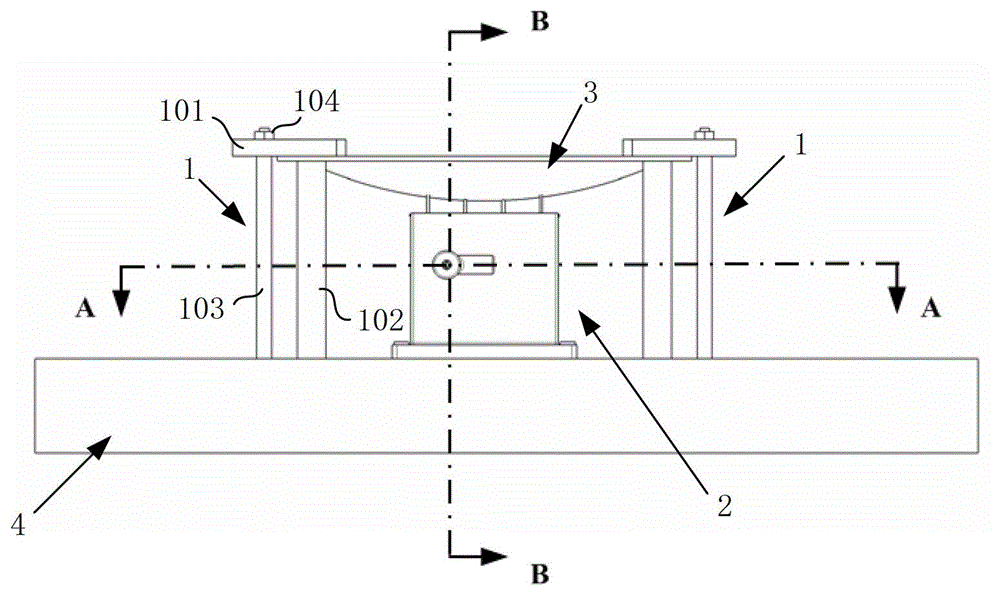

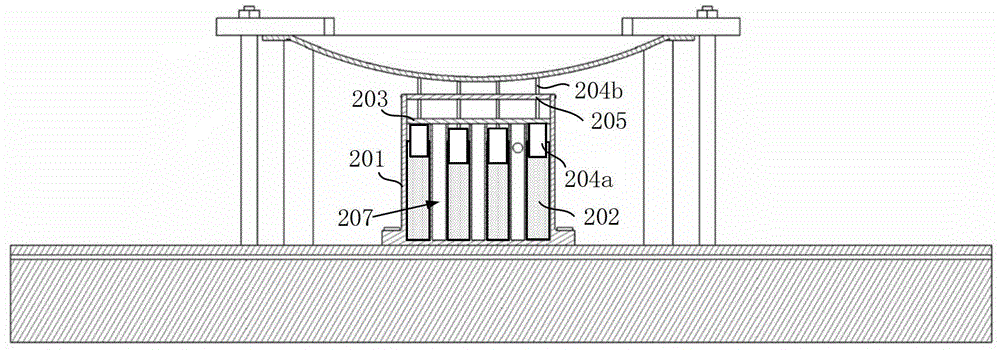

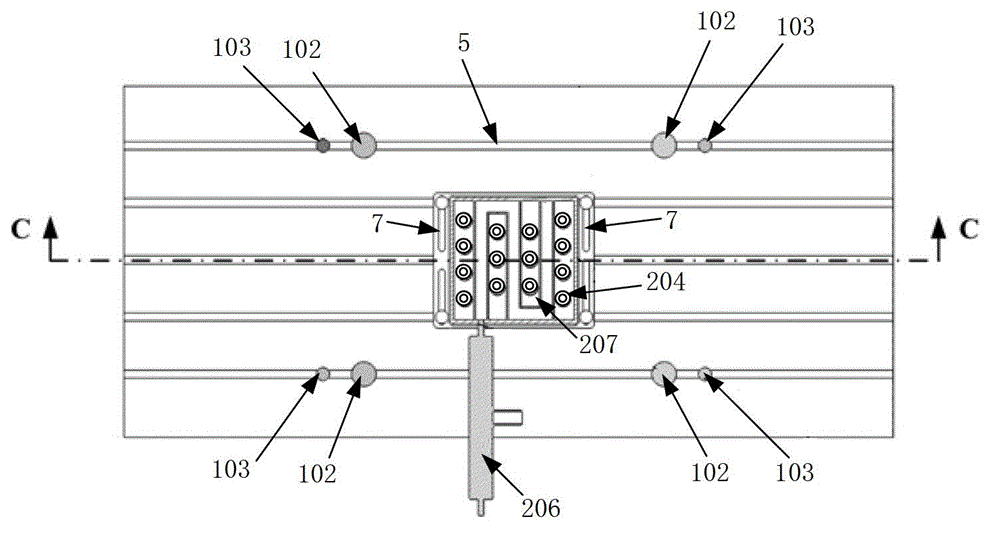

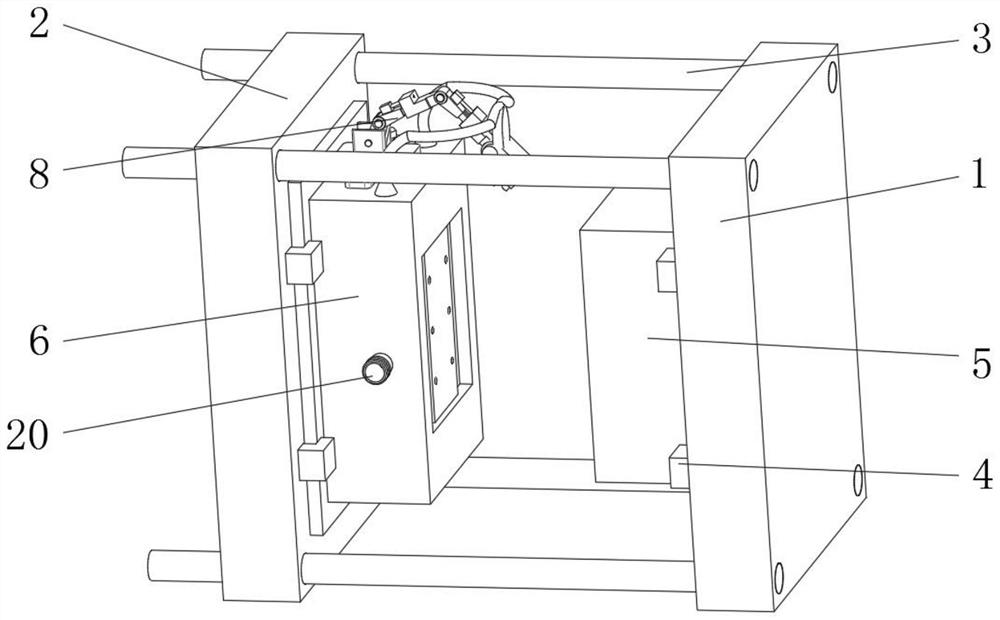

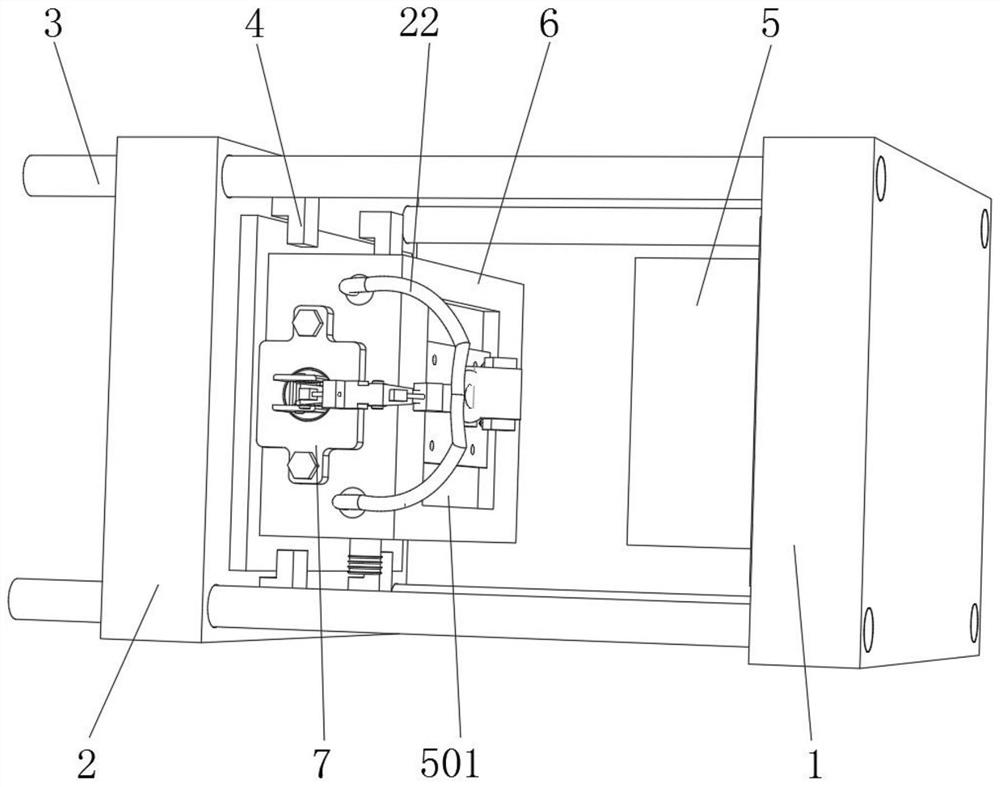

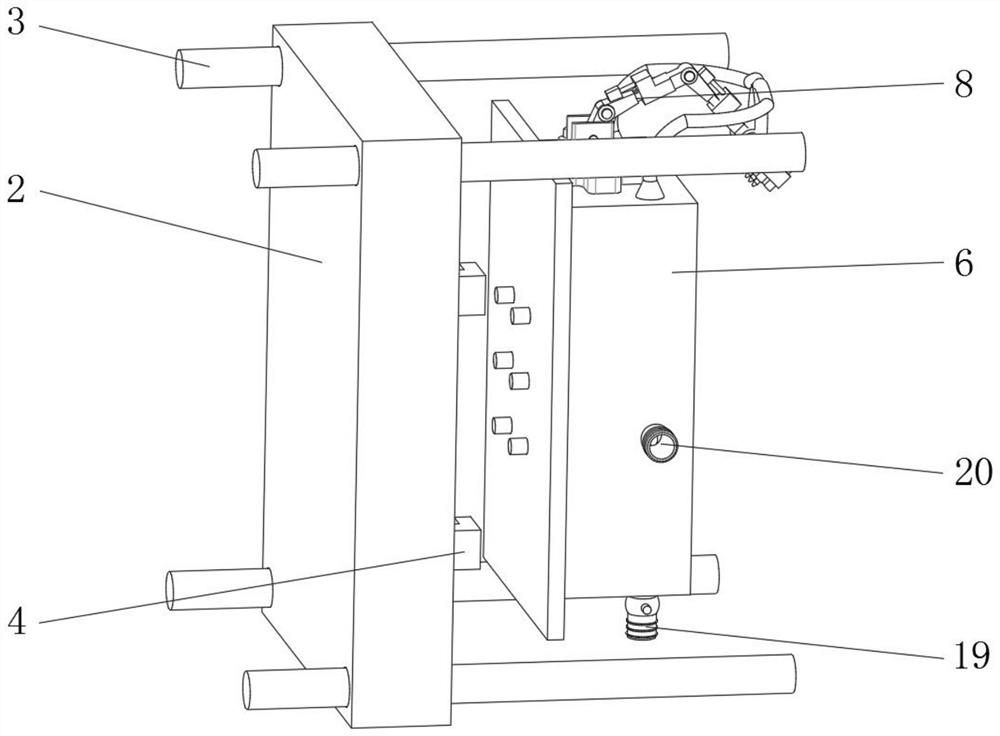

Freezing fixation flexible clamp used for numerical control cutting machining of thin-walled part

InactiveCN103100907BGood effectHigh quality and efficient processingPositioning apparatusMetal-working holdersNumerical controlProcess systems

The invention discloses a freezing fixation flexible clamp used for numerical control cutting machining of a thin-walled part. The freezing fixation flexible clamp used for the numerical control cutting machining of the thin-walled part comprises a clamping mechanism and a longitudinal positioning mechanism, wherein after the clamping mechanism clamps the thin-walled part, the thin-walled part is positioned on a lathe. The longitudinal positioning mechanism is arranged below the thin-walled part on the lathe and is wholly a container containing phase change material, a vertical support is arranged on the upper surface of the phase change material in a floating mode, and a cooling passage is designed between two opposite lateral walls in the container. Therefore, after the clamping mechanism clamps the thin-walled part, the bottom surface of the thin-walled part contacts the support and applies pressure on the support in the process of contacting, and the support is sunk. At present, cooling gas is injected into the cooling passage through a vortex tube to enable the phase change material to be converted into a solid state, the support is frozen and fixed, and longitudinal positioning of the thin-walled part is achieved. The freezing fixation flexible clamp used for the numerical control cutting machining of the thin-walled part has the advantages of being obvious in effect, convenient to achieve, low in cost, and free of pollution to the environment, and effectively improving efficiency and machining quality in the process of numerical control cutting machining of a weak-rigidity process system.

Owner:BEIHANG UNIV

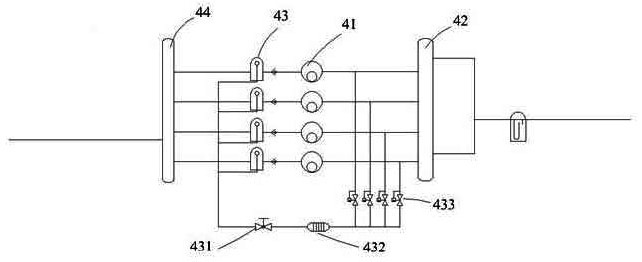

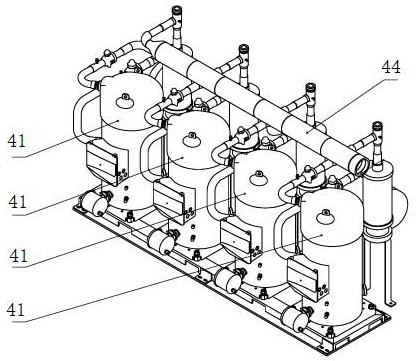

Marine liquefied ethane vaporized gas re-liquefaction device

The invention discloses a marine liquefied ethane vaporized gas re-liquefaction device. The marine liquefied ethane vaporized gas re-liquefaction device comprises an ethane vaporized gas loop and a three-stage compressed mixed refrigerant refrigeration loop. The ethane vaporized gas loop and the three-stage compressed mixed refrigerant refrigeration loop exchange heat through a heat exchanger so that ethane vaporized gas can be liquefied. The ethane vaporized gas loop comprises a BOG compressor. The three-stage compressed mixed refrigerant refrigeration loop comprises a low-pressure refrigeration compressor, a medium-pressure refrigeration compressor, a high-pressure refrigeration compressor, a low-pressure circulation throttle valve, a medium-pressure circulation throttle valve, a high-pressure circulation throttle valve, a medium-pressure gas-liquid separator and a high-pressure gas-liquid separator. A condenser is mounted between the high-pressure circulation throttle valve and the high-pressure refrigeration compressor. A BOG throttle valve and a BOG gas-liquid separator are successively arranged behind the heat exchanger. By the adoption of the marine liquefied ethane vaporized gas re-liquefaction device, the ethane vaporized gas can be recovered and used, and the waste of ethane is avoided.

Owner:江苏华滋能源工程有限公司

Die-casting die with cooling mechanism and using method of die-casting die

The invention relates to the technical field of die-casting dies, and discloses a die-casting die with a cooling mechanism and a using method of the die-casting die. The die-casting die comprises a fixed die insert and a movable die insert, the fixed die insert and the movable die insert are connected through a guide rod, and fixing pieces are arranged on the opposite circumferential sides of the fixed die insert and the movable die insert. According to the die-casting die with the cooling mechanism, after high-temperature liquid metal is injected into a die groove, a movable die is rapidly heated, cold water in a water storage cavity is rapidly heated and boiled to generate a large amount of steam, the steam is collected in a gas collection chamber, a separation pipe is used for separating water vapor from water, the water vapor is led into the gas collection chamber, the water flows back into the water storage cavity through through holes in a separator and is discharged through a water outlet, cold water is introduced through a water inlet formed above the bottom of the separation pipe all the time, so that part of water vapor in the separation pipe is liquefied into water when being cooled, and the damage to water cooling equipment caused by the fact that the water vapor and the water are discharged through the water outlet after being rapidly formed is avoided.

Owner:尚锟

Process and system for preventing excessive cracking

PendingCN107586556AImprove oil yieldAvoid aggregationLiquid hydrocarbon mixture productionBoiling pointPetroleum

The invention relates to the fields of petroleum, chemical engineering and cracking, and particularly relates to a process and a system for preventing excessive cracking. The process has the main characteristics that a plurality of temperature sections are divided according to different temperatures of cracking oil gas, the oil gas generated by cracking is led out of a cracker in time to carry outcooling dust removal, so that the excessive cracking of the oil gas is reduced, the loss of the oil gas is avoided, and the oil yield is increased; the led-out oil gas is subjected to reverse spray by adopting corresponding cooling and refluxing components; the temperature of the oil gas is reduced and dust in the cracking oil gas is removed in a shortest time by control process parameters, so that the maximum liquefaction of high-boiling-point components in the cracking oil gas is realized, the polymerization of unsaturated hydrocarbons in the cracking oil gas is avoided, and the oil yield and the oil-product quality are improved.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

Post-treatment method of hydrogen sulfide

ActiveCN113387333AAvoid generatingSimplified post-processing stepsHydrogen sulfidesLiquid statePhysical chemistry

The invention provides a post-treatment method of hydrogen sulfide. The method comprises chilling of hydrogen sulfide synthesis gas and backflow of hydrogen sulfide. According to the invention, by selecting a chilling tower, the generation of polysulfide is avoided, the post-treatment step of the polysulfide is simplified, and the liquefaction of sulfur entrained in the hydrogen sulfide synthesis gas can be realized in one step, wherein the purity of the prepared pure hydrogen sulfide reaches 99.95%, and the polysulfide is trace; liquid-state hydrogen sulfide is selected as a low-temperature medium, and other cooling mediums are not introduced, so that secondary treatment is avoided; and in the hydrogen sulfide liquefaction process, released heat can be recycled, and heating and heat preservation of solid sulfur or a hydrogen sulfide reactor, a reaction pipeline and the like are carried out.

Owner:SHANDONG XINHECHENG AMINO ACID

Method used for extracting nutrients via pulp refining and enzymatic hydrolysis of enteromorpha, and preparing enteromorpha organic composite fertilizer

PendingCN107324915AHigh retention rateEasy to extractAnimal feeding stuffAmmonium salt fertilisersNutrientChemistry

The invention belongs to the technical field of enteromorpha rapid high efficiency treatment and utilization, and organic fertilizer production, and discloses a method used for extracting nutrients via pulp refining and enzymatic hydrolysis of enteromorpha, and preparing an enteromorpha organic composite fertilizer from the nutrients. The method comprises follow steps: harvested fresh enteromorpha is immersed in fresh water to remove salt and sand, and is smashed using a large-size waterweed pulverizer; physical pulp refining is carried out using a large-size pulping machine; enteromorpha nutrients are extracted; and enteromorpha is subjected to rapid liquefaction so as to obtain enteromorpha slurry; the obtained enteromorpha slurry is subjected to enzymatic hydrolysis and distillation condensation, phosphorylation is carried out with a phosphorylation agent, and combination of inorganic fertilizers is carried out so as to obtain the enteromorpha organic composite fertilizer. According to the method, fresh enteromorpha is subjected to pulp refining and enzymatic hydrolysis so as to extract the nutrients, so that a difficult drying step is avoided; investment cost is low; cost is low; efficiency is high; capacity is large; enteromorpha environment-friendly treatment is realized preferably; and large environment pollution caused by large scale enteromorpha is eliminated.

Owner:RIZHAO XURI COMPOSITE MATERIALS

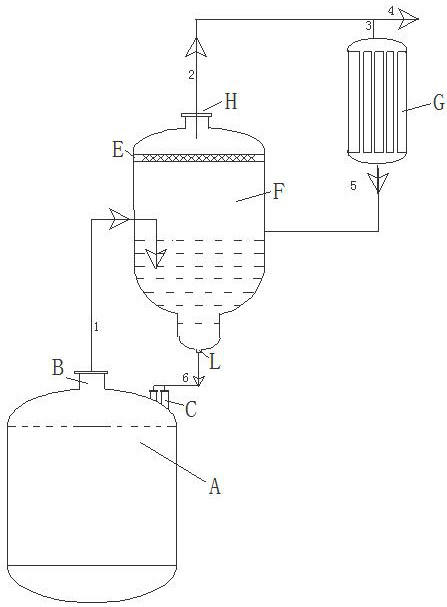

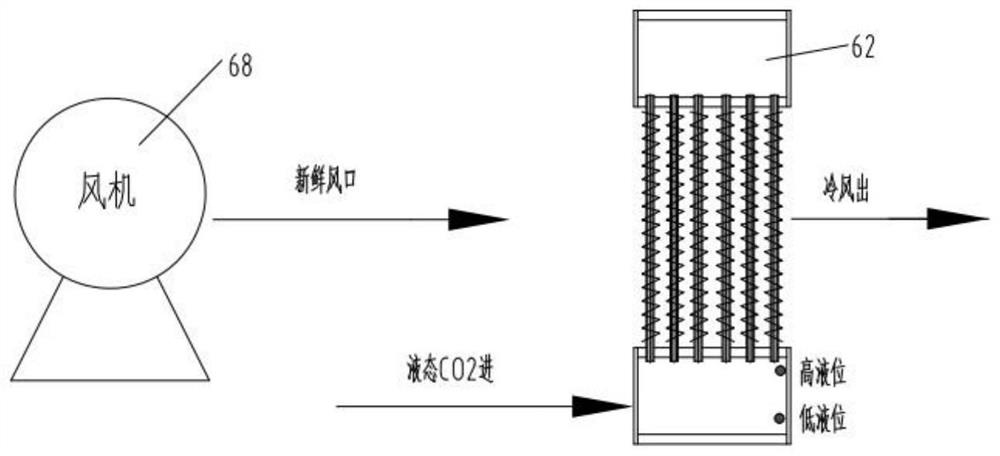

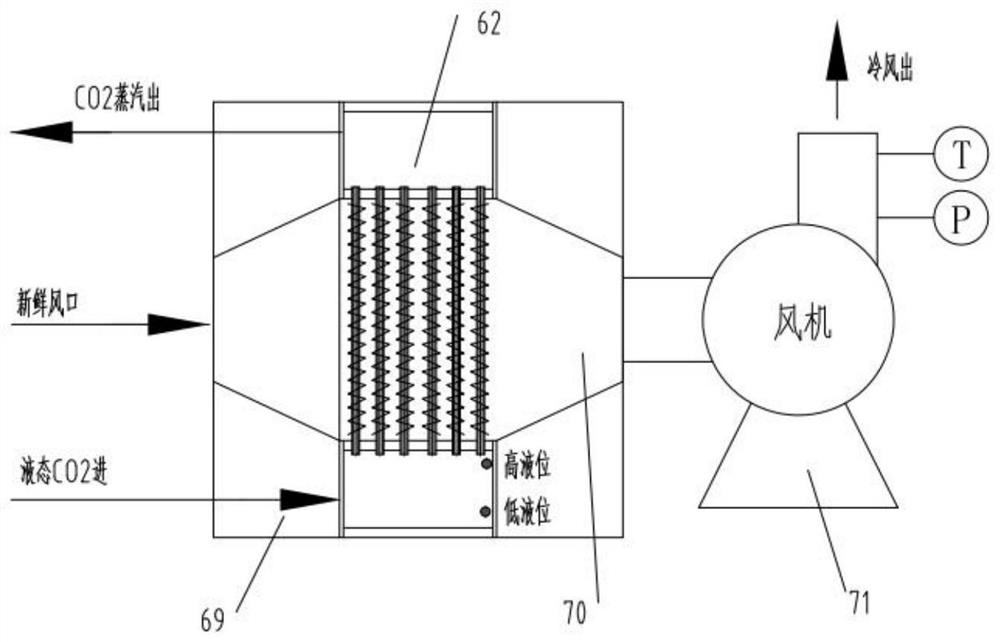

Vehicle-mounted carbon dioxide phase change circulating refrigerating system, circulating method and vehicle-mounted refrigerator

PendingCN113375358AReduce the temperatureRealize the refrigeration processAir-treating devicesMechanical apparatusCo2 storageElectrical battery

The invention discloses a vehicle-mounted carbon dioxide phase change circulating refrigerating system, a circulating method and a vehicle-mounted refrigerator. The refrigerating system involves a battery bin group, a vehicle-mounted engine, an air compressor, at least two liquid CO2 storage tanks arranged in parallel and an evaporator, wherein the liquid CO2 storage tanks are connected with the air compressor; and the evaporator is connected with the liquid CO2 storage tanks so as to alternately receive a liquid CO2 refrigerant provided by the liquid CO2 storage tanks and gasify the liquid CO2 refrigerant in the evaporator, and heat exchange is carried out through sensible heat released by cooling of a secondary refrigerant flowing through the outer surface of the pipe wall of the evaporator. According to the vehicle-mounted carbon dioxide phase change circulating refrigerating system, the liquid CO2 refrigerant reverse circulation principle is used for refrigeration, the liquid CO2 refrigerant is fed into the evaporator through high-pressure air in a pressed mode to be gasified into steam, latent heat needs to be absorbed in the gasification process, the absorbed latent heat comes from the sensible heat released by cooling of cold-carrying fresh air flowing through the surface of the evaporator, and after the cold-carrying fresh air releases the sensible heat, the temperature is reduced to achieve the vehicle-mounted refrigeration process.

Owner:上海颐柏企业管理有限公司

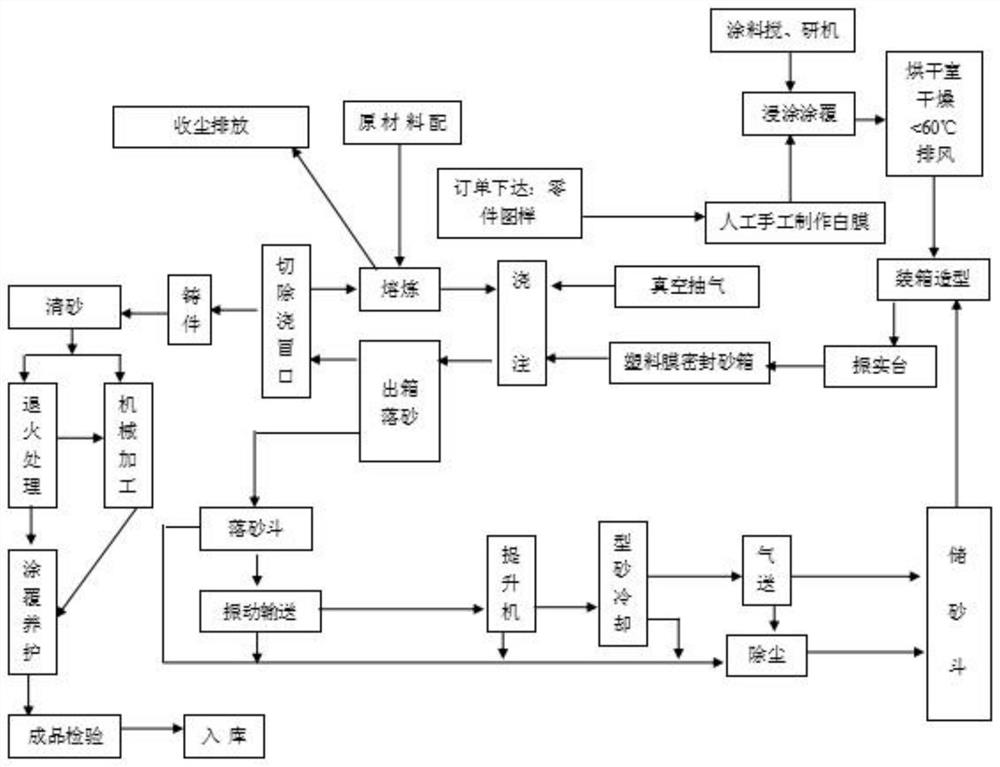

Lost foam casting method

PendingCN113996753AQuick ClearImprove liquidityFoundry mouldsMould handling/dressing devicesPumping vacuumMolding sand

The invention discloses a lost foam casting method in the technical field of lost foam casting. The method comprises the following steps: lost foam drawing, mold manufacturing, molding sand molding, jolt ramming, sealing and vacuumizing treatment, formwork elimination, casting mold pouring, waste gas purification treatment, casting post-treatment and molding sand recovery. After a formwork is manufactured, the formwork in a sand mold is heated, the heating lasts for a period of time, the formwork is heated and converted from solid into liquid, formwork liquefying is realized, and the liquefied formwork is discharged from the sand mold, so that the replacement of the formwork is effectively realized, a workpiece cavity is conveniently and quickly formed, and a casting workpiece is conveniently formed by subsequently pouring liquid metal. The heating temperature of the sand mold is increased for a period of time, so that residual liquid formwork raw materials are converted into gas, clean and rapid removal of the formwork materials is achieved, the casting quality of castings can be guaranteed, waste gas can be collected, the mold sand can be recycled and reused, the production cost is reduced, energy consumption is reduced, and the environment friendliness is high.

Owner:云南领峰机械制造有限公司

Method for preparing sugar alcohol ethylation biology liquid fuel

The invention discloses a method for preparing sugar alcohol ethylation biology liquid fuel, and belongs to the field of fuels. The method includes the following steps: mixing sucrose, mannitol and glycerin; adding sodium hydroxide and monochloroethane for reaction; enabling the mixture after reaction to be subjected to standing; adjusting the pH value of the supernatant, and then adding trichloromethane in the supernatant to obtain ethylation mixed liquor; taking fruits of cornus wilsoniana, and obtaining the bio-oil of fruits of cornus wilsoniana after processes of soaking with n-butyl alcohol, grinding, filtration, and the like; mixing a catalyst prepared from calcium oxide with the bio-oil, so as to obtain hydrocarbon-enriched bio-oil; mixing the ethylation mixed liquor with the hydrocarbon-enriched bio-oil to obtain the sugar alcohol ethylation biology liquid fuel. According to the invention, sucrose, mannitol and monochloroethane (an etherifying agent) is successfully subjected to one-step reaction to realize liquidation of oligosaccharide and sugar alcohol without generating gaseous by-product, besides, the ethylation of glycerin changes fluidity and combustion performance of glycerin, and the bio-oil generated by cornus wilsoniana is added, so that the condensation point of the fuel is reduced.

Owner:梅庆波

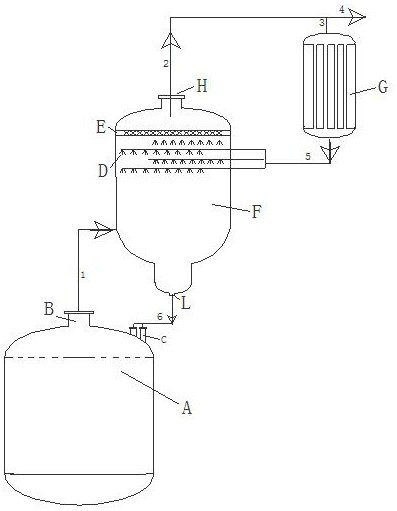

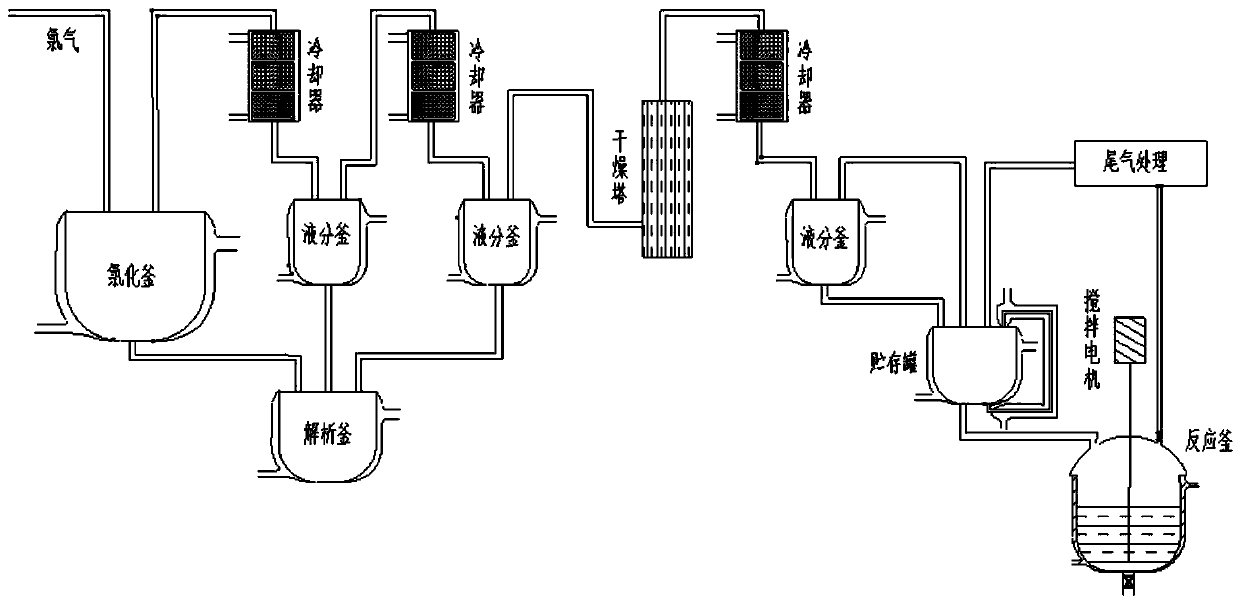

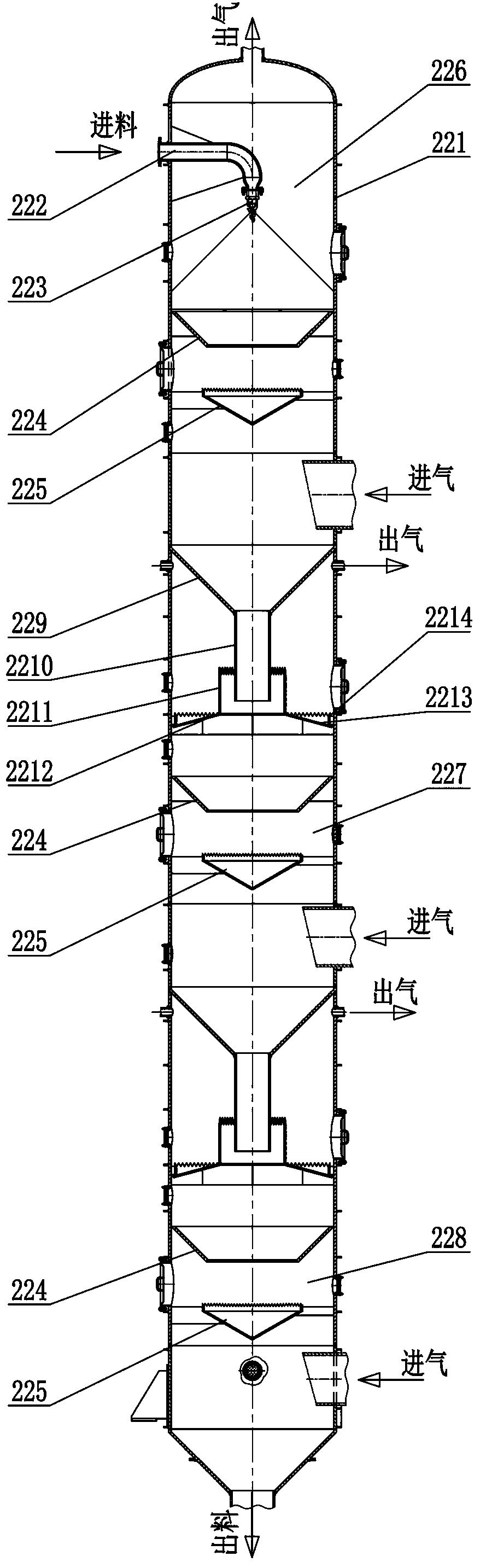

Cyanogen chloride liquefaction and gas-liquid separation method

InactiveCN111195471AAchieve liquefactionStable storageGas treatmentDispersed particle separationVapor–liquid separatorPhysical chemistry

The invention relates to a cyanogen chloride liquefaction and gas-liquid separation method, which comprises the following steps of: enabling high-temperature cyanogen chloride gas to sequentially passthrough a first-stage condenser and a first-stage gas-liquid separator to perform first-stage condensation and gas-liquid separation, setting the condensation temperature of the first-stage condenserto be -25 DEG C to -15 DEG C, enabling the mixed gas obtained after first-stage gas-liquid separation to sequentially pass through a second-stage condenser and a second-stage gas-liquid separator, conducting second-stage condensation and gas-liquid separation, setting the condensation temperature of the second-stage condenser to range from -25 DEG C to -15 DEG C, drying the mixed gas after the second-stage gas-liquid separation, enabling the dried mixed gas to sequentially pass through a third-stage condenser and a third-stage gas-liquid separator for third-stage condensation and gas-liquid separation, and setting the condensation temperature of the third-stage condenser to be -25 DEG C to -15 DEG C. Through three-stage condensation and three-stage gas-liquid separation processes, most ofcontinuously generated high-temperature cyanogen chloride gas can be liquefied, stable storage of liquid is achieved through low-temperature storage, and storage and metering are facilitated.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

liquid-based tableting method

ActiveCN109030151BFully automaticWithout human interventionPreparing sample for investigationPad printingMedicine

The invention provides a liquid-based film-making method, comprising the following steps: sputum cup processing step: processing the sample liquid inside the sputum cup to obtain a pretreatment liquid; filter cup action step: filtering the pretreatment liquid in the filter cup to obtain Film-making liquid; slide glass action steps: the glass slide touches the filter cup filled with the film-making liquid for pad printing to obtain a liquid-based sheet. The entire film-making process of the present invention can be fully automatic without human intervention; real liquefaction film-making is realized: all samples are automatically added with digestive juice and buffer solution to realize sample liquefaction.

Owner:上海皓信生物科技有限公司

Circulation system for seawater thermoelectric power generation device

ActiveCN112943397BImplement hybrid processingAchieve liquefactionSeawater treatmentWater/sewage treatment by heatingWater vaporEngineering

The invention discloses a circulation system for a seawater temperature difference power generation device. By adding a valve, the current limitation of the No. 2 water pipe and the No. 4 water pipe is realized, and the water pressure of the sea water is used to replace the two cold and hot sea water pumps. The energy consumption of the device is reduced by 90%. By adding a distributor, the mixed treatment between high-temperature seawater and normal-temperature seawater is realized. By adding an IDC server, the server cooling pipe can make full use of the waste heat of the IDC and carry out the seawater treatment. In order to advance the heating temperature to about 70 degrees, by adding a distiller and No. 2 condenser, there is a height difference between the distiller and the No. 2 condenser, so that the distilled water vapor is transported to the No. 2 condenser in a gaseous state. , By adding the No. 2 condenser, the No. 2 condenser of the condensing equipment can be used for air-cooled cooling and heat exchange to produce water vapor liquefaction.

Owner:房盼盼

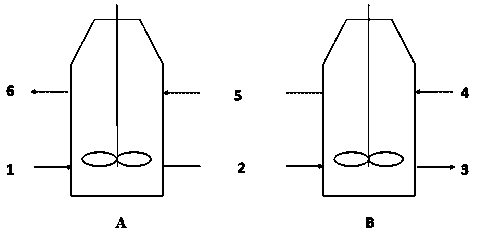

Liquefying and purifying device for chlorine in electrolytic magnesium chloride

InactiveCN113203249AAchieve liquefactionAchieve purificationSolidificationLiquefactionVapor–liquid separatorPhysical chemistry

The invention relates to a liquefying and purifying device for chlorine in electrolytic magnesium chloride. The liquefying and purifying device consists of a liquefier, a pipeline A, a pipeline B, a pipeline C, a pipeline D, a pipeline E, a pipeline F, a pipeline G, a gas-liquid separator, a liquid chlorine storage tank, an intermediate tank, a tail gas treatment tank, a chlorine inlet pipe and valves, wherein the chlorine inlet pipe is arranged at the top of the liquefier; one side of the upper portion of the liquefier is connected with the gas-liquid separator through a pipeline A, and the other side of the upper portion of the liquefier is connected with the tail gas treatment tank through the pipeline G; one side of the gas-liquid separator is connected with the bottom of the liquefier through the pipeline C; the bottom of the gas-liquid separator is connected with one side of the liquid chlorine storage tank through the pipeline B, and the other side of the liquid chlorine storage tank is connected with the bottom of the tail gas treatment tank through the pipeline F; the bottom of the liquid chlorine storage tank is connected with the top of the intermediate tank through the pipeline D; the pipeline E is arranged on a side of the liquid chlorine storage tank; and the valves are respectively arranged on the pipeline A, the pipeline B, the pipeline C, the pipeline D, the pipeline E, the pipeline F and the pipeline G. According to the liquefying and purifying device disclosed by the invention, liquefying, purifying and collecting of the chlorine in the electrolytic magnesium chloride production are realized, and environmental pollution is avoided.

Owner:ZUNYI TITANIUM

LED (light emitting diode) chip production wastewater treatment device

PendingCN110498550AChange pHPH value consistentWater treatment parameter controlTreatment involving filtrationFiltrationEvaporation

The invention belongs to the technical field of wastewater treatment and in particular discloses an LED (light emitting diode) chip production wastewater treatment device. Aiming at the problem that the production efficiency is low as operation water discharge is instable and the medicine consumption is large in conventional wastewater treatment, the invention discloses a scheme that the method comprises the following steps: S1, firstly, centrally conveying produced wastewater into a wastewater tank, allowing the wastewater to stand in the wastewater tank to precipitate insoluble substances inthe wastewater, and discharging the wastewater into a reaction tank through a water discharge tube after standing is completed; and S2, putting sodium hydroxide of solid powder into the wastewater tank, and dissolving the sodium hydroxide into the water. Through steps of precipitation, evaporation, condensation, filtration and the like of wastewater, the wastewater can be treated, and the purposeof up-to-standard emission of the wastewater can be achieved; and as each treatment process of the technical scheme is independently operated, dosages can be accurately controlled, a stable water outlet quantity can be ensured, and the production efficiency can be effectively improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

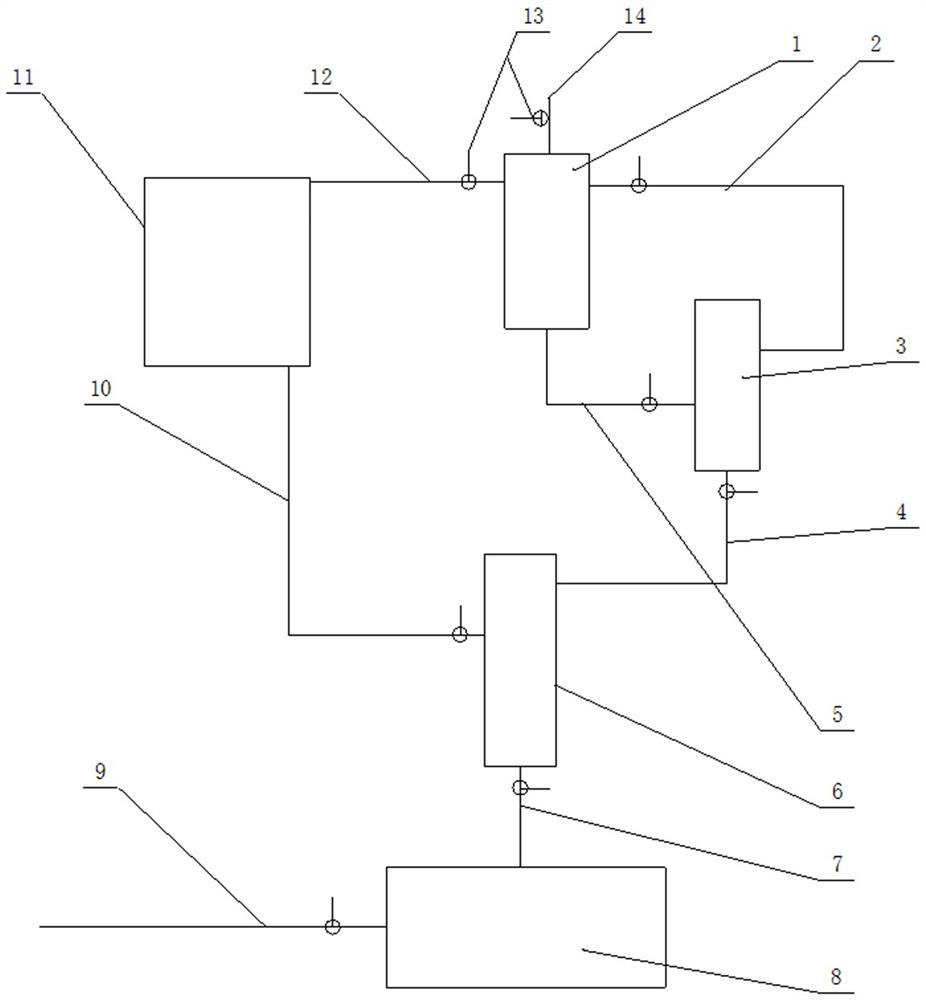

Energy-saving liquefaction system for production of alcohol from starchiness raw materials

PendingCN110643490AReduce consumptionReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholChaptalization

The invention belongs to the technical field of equipment for the production of alcohol from starchiness raw materials, and particularly relates to an energy-saving liquefaction system for the production of the alcohol from the starchiness raw materials. The energy-saving liquefaction system comprises a mixing spiral conveyer, a primary preheating device, a liquefying preheating system, a steam heating device, a liquefying conveyor pump, a liquefying system, a liquefying mash cooling system, a saccharifying tank, a saccharifying liquid cooling system, a saccharifying liquid cache tank, a saccharifying liquid high-temperature pump, a saccharifying liquid low-temperature pump, a heat exchanger and a tail gas condensation washing discharge device. According to the energy-saving liquefaction system, secondary steam generated in the flash evaporation and cooling process of liquified mash the evaporation and cooling process of saccharified liquid after liquefying the starch raw materials isrecovered, the starch raw materials are preheated by using the recovered secondary steam, temperature rising and pre-liquefying are conducted on the starch raw materials step by step, thus the recovery and reuse of the secondary steam are achieved, the purposes of reducing energy consumption, cooling water consumption, energy conservation and emission reduction are achieved, thus the production cost of alcohol is lowered, and the competitiveness of enterprises is improved.

Owner:孙发喜

A domestic waste pretreatment device and pretreatment method thereof

ActiveCN111659711BAchieve dehydrationAchieve liquefactionTransportation and packagingSolid waste disposalPretreatment methodStructural engineering

The invention discloses a domestic garbage pretreatment device and a pretreatment method thereof, belonging to the technical field of garbage pretreatment, comprising: a base; an outer cylinder arranged on the upper side of the base; To achieve support, the upper part of the outer cylinder is designed to be open, and the lower part of the outer cylinder is designed to be closed. tube; the annular baffle arranged inside the outer cylinder, the annular baffle is connected to the support feet through multiple sets of heat-conducting connecting rods, the upper and lower parts of the annular baffle are designed with openings; the inner cylinder arranged inside the annular baffle, the inner cylinder The upper part is designed to be open, and the lower part of the inner cylinder is designed to be closed, and the circumferential surface of the inner cylinder is provided with a plurality of evenly distributed drainage holes; the invention integrates crushing, drying and solid-liquid separation in a clever way.

Owner:JIANGSU HEHAI WATER SUPPLY & DRAINAGE EQUIP CO LTD

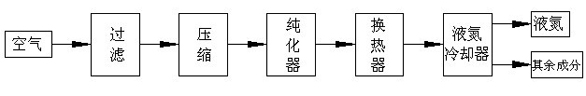

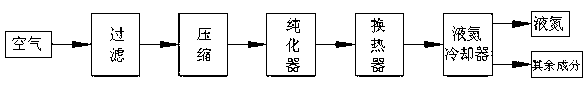

Production device and production process for producing ultra-pure oxygen and liquid nitrogen by adopting pre-cooling system

PendingCN113390231AAchieve liquefactionMeet sales needsSolidificationLiquefactionProcess engineeringRefrigeration

The invention belongs to a production device and a production process for producing ultra-pure oxygen and liquid nitrogen by adopting a pre-cooling system. The production device comprises an ultra-pure oxygen production system and a liquid nitrogen preparation system, the ultra-pure oxygen production system comprises an oxygen raw material storage tank, and the oxygen raw material storage tank is connected with an ultra-pure oxygen storage tank through a raw material heat exchange unit and a thermal coupling rectifying tower; the liquid nitrogen preparation system and a cooling capacity supply system provide cooling capacity for the raw material heat exchange unit; and the liquid nitrogen preparation system provides cold energy for the thermal coupling rectifying tower and a top condenser at the top of the thermal coupling rectifying tower. The production device has the advantages that the structure is simple, the flow design is reasonable, the upper and lower towers and the circulating refrigeration process are adopted, the occupied area of the device is small, the investment is low, the product is stable, and the liquid nitrogen byproduct can be obtained while the ultra-pure oxygen product is obtained.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

Deoxidation and denitrification system for oxygen-containing coal bed gas

The invention discloses a deoxygenation and denitrification system for oxygen-containing coal bed gas. The system includes a cold box, a rectification tower, a coal bed gas deoxidation and denitrification mechanism, a mixed refrigerant circulation mechanism and a nitrogen refrigerant circulation mechanism; the mixed refrigerant circulation mechanism provides cooling capacity for the cold box; The cooling capacity is provided by the box and the rectification tower; the coalbed methane deoxygenation and denitrification mechanism includes the feed gas pipeline, the recondenser arranged at the top of the rectification tower and the reboiler arranged at the bottom of the rectification tower; the feed gas pipeline and all The above-mentioned cold box is connected, and then connected with the reboiler after being drawn out from the cold box; the feed gas pipeline is drawn out from the reboiler and then enters the cold box, and then connected with the rectification tower after being drawn out from the cold box; The gas phase outlet of the reboiler is connected with the cold box through the pipeline, and the pipeline is connected with the LNG storage tank after being cooled by the cold box. The invention can realize the liquefaction of coalbed methane with a methane content of 30-90% in raw material gas, reduce carbon emission, and recover natural gas resources to the greatest extent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Evaporation and concentration system

ActiveCN111732143AIncrease throughputStart fastSpecific water treatment objectivesWater/sewage treatment by heatingRefrigerantCold medium

The invention discloses an evaporation and concentration system. The system comprises: a first evaporation tank provided with a first steam outlet and a first concentrated solution outlet; a second evaporation tank provided with a second steam outlet and a second concentrated solution outlet; a decompression device; a first heat exchanger connected with the first evaporation tank and located outside the first evaporation tank; a heat source device comprising a compressor unit and an air inlet port, wherein the compressor unit comprises a plurality of compressors arranged in parallel, each compressor is connected with the air inlet port and the first heat exchanger, and the air inlet port is used for distributing a gaseous refrigerant into each compressor to form a heat exchange medium provided for the first heat exchanger; a second heat exchanger connected with the first steam outlet and the second evaporation tank and positioned outside the second evaporation tank; a distilled water tank connected with the second heat exchanger and the second steam outlet; a preheating device connected with the second evaporation tank; and a cooling device. The evaporation and concentration systemis good in use effect.

Owner:昆山威胜达环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com