Deoxidation and denitrification system for oxygen-containing coal bed gas

A coalbed methane and denitrification technology, applied in the denitrification system and deoxygenation field, can solve the problems of reducing separation and liquefaction processing capacity, consuming large amounts of methane and reacting with oxygen, low efficiency of auxiliary mechanical refrigeration, etc. The effect of high rate and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

[0028] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0029] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

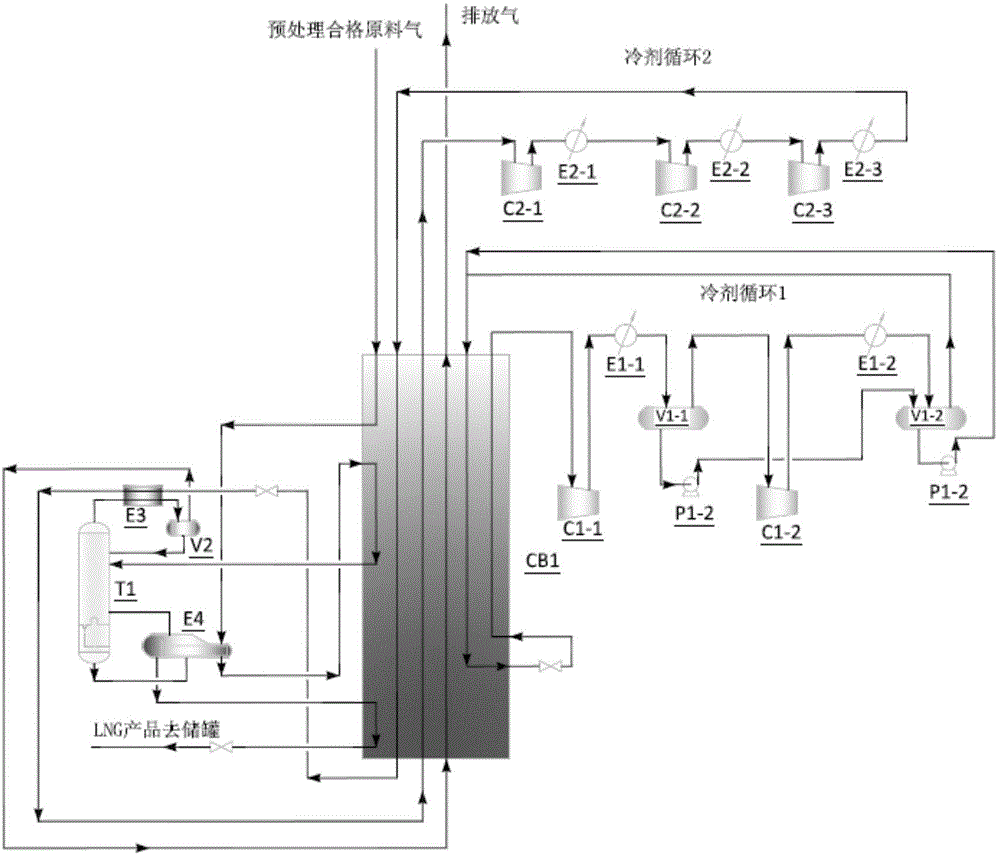

[0030] like figure 1 As shown, the oxygen-containing coalbed methane deoxygenation and denitrification system provided by the present invention includes a cold box CB1, a rectification tower T1, a coalbed methane deoxygenation and denitrification mechanism, a mixed refrigerant circulation mechanism and a nitrogen refrigerant circulation mechanism; in this system, The mixed refrigerant circulation mechanism provides cooling capacity for the cold box CB1, and the nitrogen refrigerant circulation mechanism provides cooling capacity for the cold box CB1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com