A domestic waste pretreatment device and pretreatment method thereof

A pretreatment device, a technology for domestic waste, applied in grain processing, chemical instruments and methods, transportation and packaging, etc., can solve problems such as inability to combine together, environmental hazards, time-consuming and labor-intensive, etc. The effect of liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

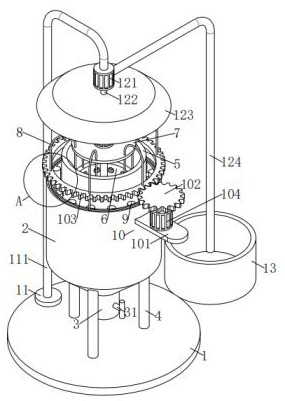

[0048] see Figure 1-4 , a domestic waste pretreatment device, comprising:

[0049] base1;

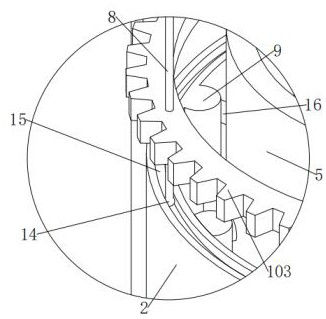

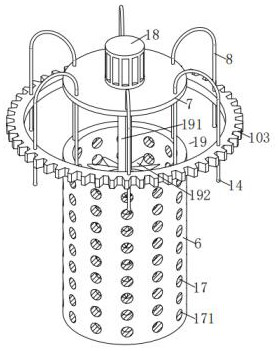

[0050] The outer cylinder 2 arranged on the upper side of the base 1, the outer cylinder 2 and the base 1 are fixedly connected by a plurality of support feet 4 to realize support, the upper parts of the plurality of outer cylinders 2 are designed as openings, and the lower parts of the outer cylinder 2 are designed as closed , the supporting feet 4 are used to install and support the outer cylinder 2 well, the lower part of the outer cylinder 2 is fixedly provided with a water outlet 3, and a water outlet valve 31 is installed on the water outlet 3, and the water outlet 3 is used to realize the discharge of waste liquid, namely achieve drainage;

[0051] A plurality of far-infrared heating tubes 9 fixedly arranged on the inner wall of the outer cylinder 2 in an annular array, the far-infrared heating tubes 9 have a good heating effect, that is, the drying can be realized by the far-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com