Energy-saving liquefaction system for production of alcohol from starchiness raw materials

A technology of starchy raw materials and alcohol, applied in biochemical instruments, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of heat consumption and waste, large cooling water consumption, cooling water consumption, etc., and achieve high absorption utilization rate , reduce production costs, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

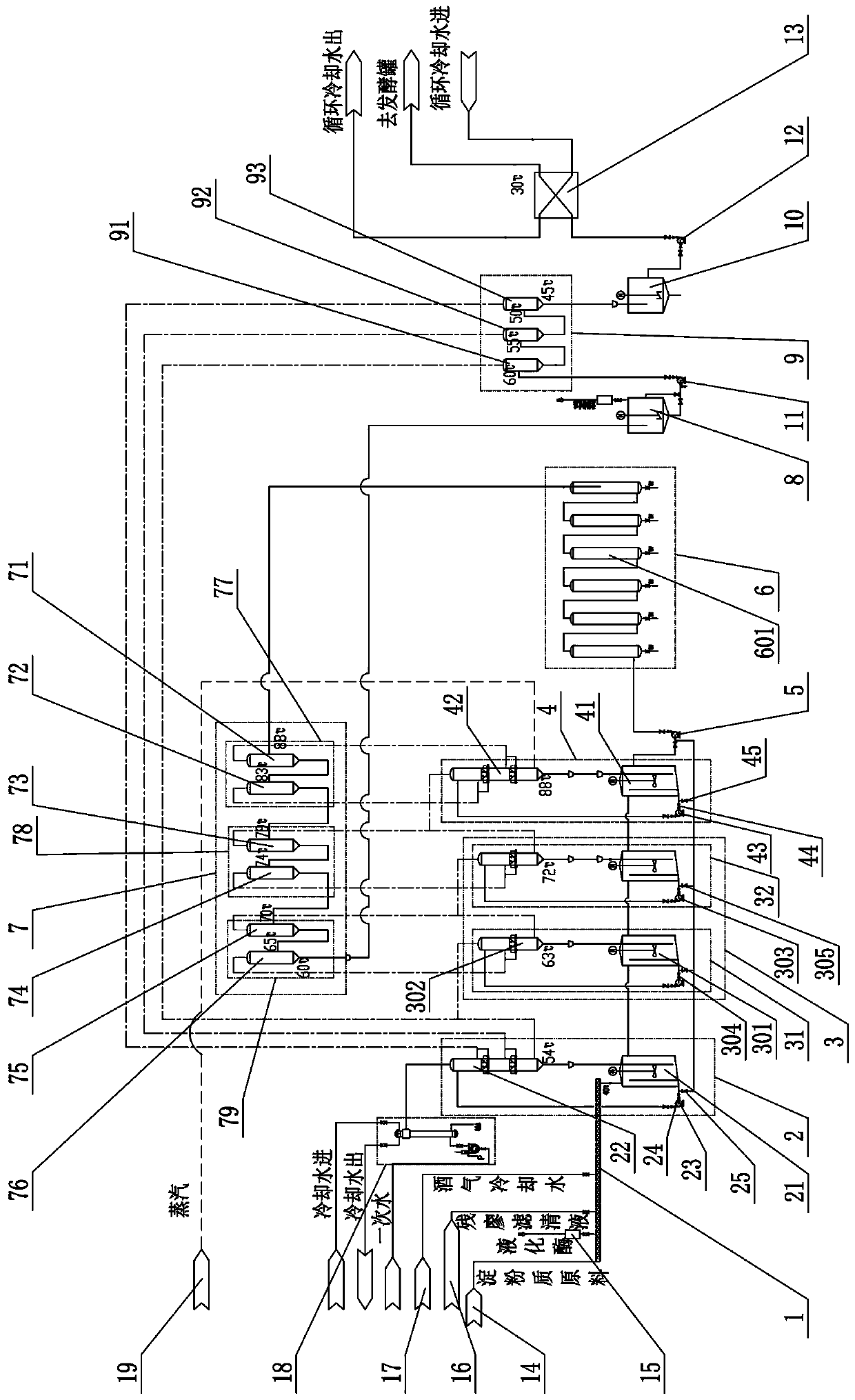

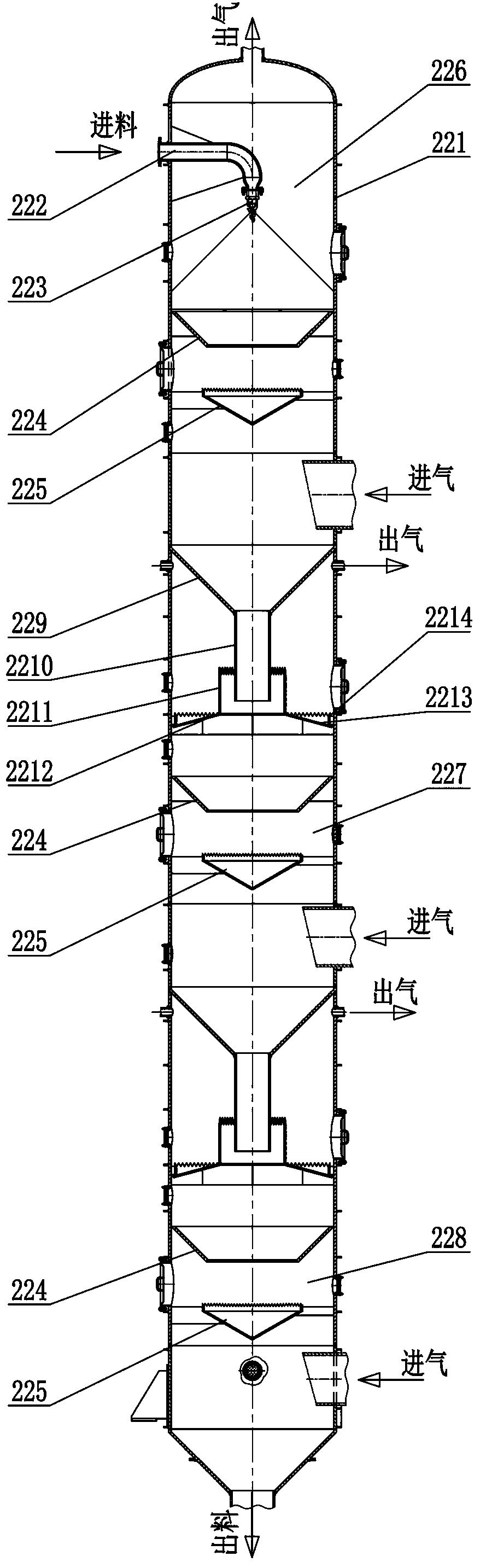

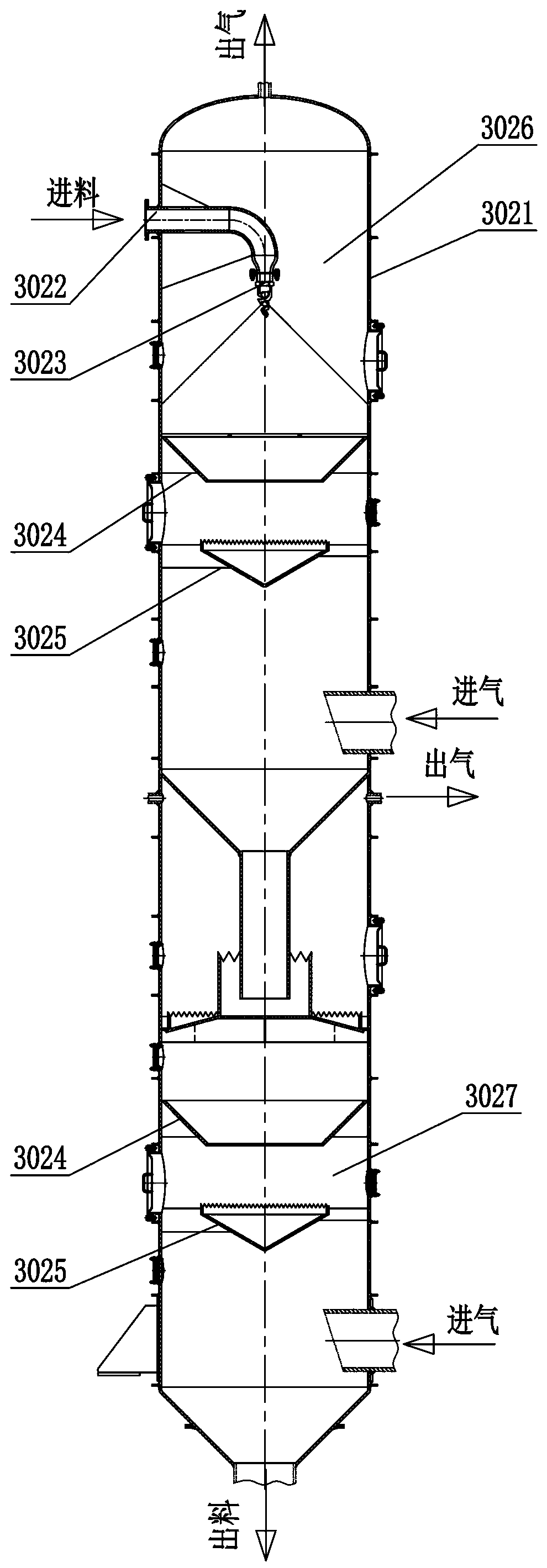

[0027] Such as figure 1 As shown, an energy-saving liquefaction system for producing alcohol from starchy raw materials, including mixing screw conveyor 1, primary preheating device 2, liquefaction preheating system 3, steam heating device 4, liquefaction delivery pump 5, liquefaction system 6, liquefaction Mash cooling system 7, saccharification tank 8, saccharification liquid cooling system 9, saccharification liquid buffer tank 10, saccharification liquid high temperature pump 11, saccharification liquid low temperature pump 12, heat exchanger 13 and tail gas condensation washing discharge device 18, the mixing material The screw conveyor 1 mixes the starchy raw material, liquefaction enzyme, distilled residual mash filtrate 16 and wine gas cooling water 17 to form a mixture evenly during the conveying process; the primary preheating device 2 uses the saccharification liquid to cool down The evaporated secondary steam preheats the mixed material, and the mixed material is i...

Embodiment 2

[0049] Such as Figure 4 As shown, Example 1 is repeated, with the following differences: the liquefaction system 6 includes three liquefaction stirring tanks 602, and the three liquefaction stirring tanks 602 are sequentially connected in series, including the first liquefaction stirring tank 602, the second liquefaction stirring tank 602 and the second liquefaction stirring tank 602. Three liquefaction stirring tanks 602, the feed port of the first liquefaction stirring tank 602 is connected to the discharge port of the jet liquefier, the discharge port of the first liquefaction stirring tank 602 is connected to the feed port of the second liquefaction stirring tank 602, and the feed port of the second liquefaction stirring tank 602 is connected. The discharge port of the second liquefaction stirring tank 602 is connected to the feed port of the third liquefaction stirring tank 602 , and the discharge port of the third liquefaction stirring tank 602 is connected to the feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com