Production device and production process for producing ultra-pure oxygen and liquid nitrogen by adopting pre-cooling system

A production device and pure oxygen technology, applied in the field of coupled production of ultra-pure liquid oxygen and liquefied nitrogen, can solve the problems of oxygen venting, large cooling capacity consumption, and cooling capacity waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

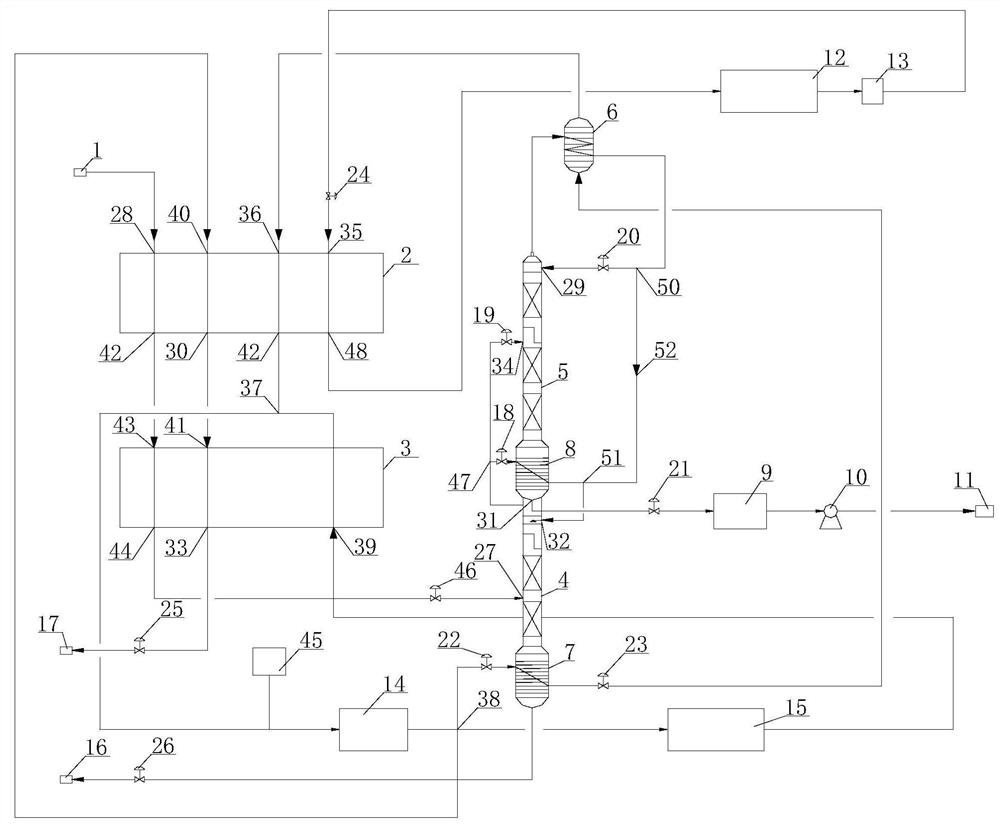

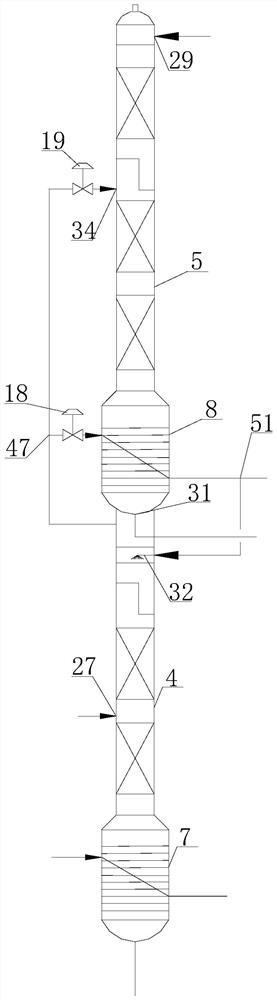

[0062] A production device for producing ultra-pure oxygen and liquid nitrogen using a pre-cooling system, including an ultra-pure oxygen production system, the ultra-pure oxygen production system includes an oxygen raw material storage tank 1, and the oxygen raw material storage tank 1 passes through a raw material heat exchange unit and heat The coupled rectification tower is connected to the ultra-pure oxygen storage tank 9; the liquid nitrogen preparation system and the cooling capacity supply system respectively provide cooling capacity for the raw material heat exchange unit; the liquid nitrogen preparation system is a thermally coupled rectification tower and a thermally coupled rectification tower top The top condenser 6 provides cooling capacity. The thermally coupled rectification tower comprises a lower rectification tower 4 and an upper rectification tower 5 arranged at the top of the lower rectification tower 4; A raw material liquid inlet 27 is connected to each ...

Embodiment 2

[0075] A production device for producing ultra-pure oxygen and liquid nitrogen using a pre-cooling system, including an ultra-pure oxygen production system, the ultra-pure oxygen production system includes an oxygen raw material storage tank 1, and the oxygen raw material storage tank 1 passes through a raw material heat exchange unit and heat The coupled rectification tower is connected to the ultra-pure oxygen storage tank 9; the liquid nitrogen preparation system and the cooling capacity supply system respectively provide cooling capacity for the raw material heat exchange unit; the liquid nitrogen preparation system is a thermally coupled rectification tower and a thermally coupled rectification tower top The top condenser 6 provides cooling capacity. The thermally coupled rectification tower comprises a lower rectification tower 4 and an upper rectification tower 5 arranged at the top of the lower rectification tower 4; A raw material liquid inlet 27 is connected to each ...

Embodiment 3

[0088] A production device for producing ultra-pure oxygen and liquid nitrogen using a pre-cooling system, including an ultra-pure oxygen production system, the ultra-pure oxygen production system includes an oxygen raw material storage tank 1, and the oxygen raw material storage tank 1 passes through a raw material heat exchange unit and heat The coupled rectification tower is connected to the ultra-pure oxygen storage tank 9; the liquid nitrogen preparation system and the cooling capacity supply system respectively provide cooling capacity for the raw material heat exchange unit; the liquid nitrogen preparation system is a thermally coupled rectification tower and a thermally coupled rectification tower top The top condenser 6 provides cooling capacity. The thermally coupled rectification tower comprises a lower rectification tower 4 and an upper rectification tower 5 arranged at the top of the lower rectification tower 4; A raw material liquid inlet 27 is connected to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com