Process and system for preventing excessive cracking

A process and cracker technology, applied in the fields of cracking, chemical industry, and petroleum, can solve the problems of lower oil yield, low oil yield, and reduced service life of equipment in the cracking process, so as to increase oil yield, increase oil yield and Oil quality, effect of avoiding polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

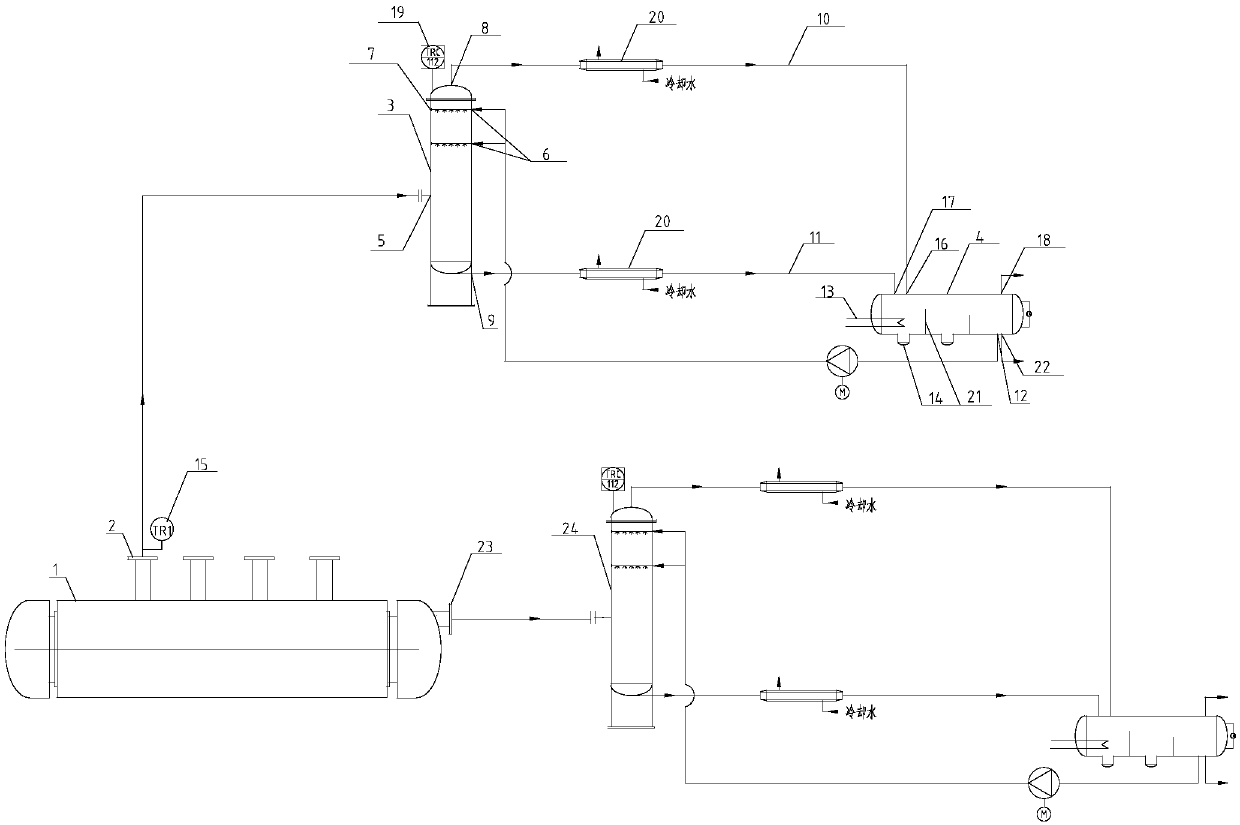

[0043] A kind of technology that prevents excessive pyrolysis, it is characterized in that: comprise the following steps:

[0044] (1) After the material to be cracked enters the cracker, along with the operation of the material to be cracked in the cracker, the oil and gas in different temperature ranges produced are discharged from the corresponding oil and gas outlet 1 and enter the corresponding purification tower;

[0045] (2) The oil gas entering the purification tower and the cooling reflux component are sprayed and contacted in reverse in the purification tower, then discharged from the purification tower and enter the corresponding collection tank;

[0046] (3) After the oil and gas entering the corresponding collection tank are cooled and settled, part of the liquid components are used as cooling reflux components in step (2), the rest of the liquid oil is discharged from the oil outlet of the oil collection tank, and the unliquefied oil and gas are discharged from th...

Embodiment 2

[0058] A kind of technology that prevents excessive pyrolysis, it is characterized in that: comprise the following steps:

[0059] (1) After the material to be cracked enters the cracker, along with the operation of the material to be cracked in the cracker, the oil and gas in different temperature ranges produced are discharged from the corresponding oil and gas outlet 1 and enter the corresponding purification tower;

[0060] (2) The oil gas entering the purification tower and the cooling reflux component are sprayed and contacted in reverse in the purification tower, then discharged from the purification tower and enter the corresponding collection tank;

[0061] (3) After the oil and gas entering the corresponding collection tank are cooled and settled, part of the liquid components are used as cooling reflux components in step (2), the rest of the liquid oil is discharged from the oil outlet of the oil collection tank, and the unliquefied oil and gas are discharged from th...

Embodiment 3

[0073] A kind of technology that prevents excessive pyrolysis, it is characterized in that: comprise the following steps:

[0074] (1) After the material to be cracked enters the cracker, along with the operation of the material to be cracked in the cracker, the oil and gas in different temperature ranges produced are discharged from the corresponding oil and gas outlet 1 and enter the corresponding purification tower;

[0075] (2) The oil gas entering the purification tower and the cooling reflux component are sprayed and contacted in reverse in the purification tower, then discharged from the purification tower and enter the corresponding collection tank;

[0076] (3) After the oil and gas entering the corresponding collection tank are cooled and settled, part of the liquid components are used as cooling reflux components in step (2), the rest of the liquid oil is discharged from the oil outlet of the oil collection tank, and the unliquefied oil and gas are discharged from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com