Post-treatment method of hydrogen sulfide

A hydrogen sulfide and sulfur technology, applied in hydrogen sulfide, chemical instruments and methods, sulfur compounds, etc., can solve the problems of catalyst pollution, hydrogen sulfide gas entrainment, unfriendly continuous operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

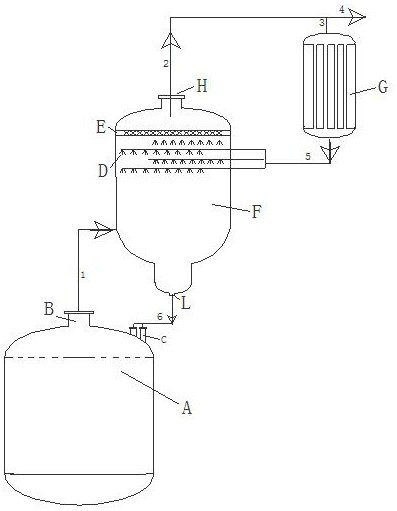

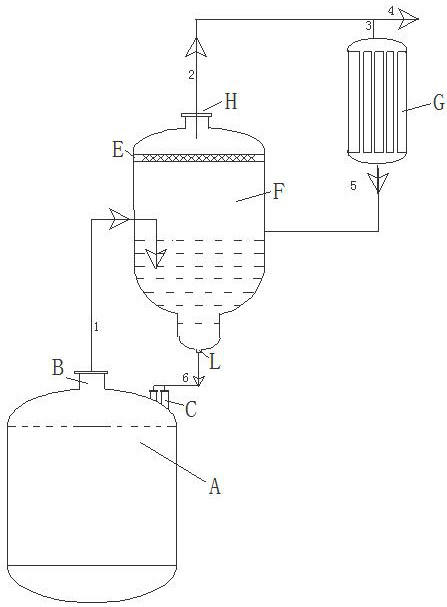

[0043] Embodiment 1 A kind of aftertreatment method of hydrogen sulfide

[0044] The sulfur obtained from the quenching tower is discharged from the liquid sulfur discharge port L, and the discharged sulfur 6 is preheated to 100°C, and enters the hydrogen sulfide reactor A through the sulfur feed pipe C, and is mixed with hydrogen and passed through the catalytic tube to obtain Hydrogen sulfide synthesis gas 1, hydrogen sulfide synthesis gas 1 is discharged from hydrogen sulfide synthesis gas outlet B at 678.35kg / h (the composition of hydrogen sulfide synthesis gas 1 is 92.44% hydrogen sulfide, 7.48% sulfur, 0.08% impurities), and the output The material temperature is 379°C, and the temperature when it enters the hydrogen sulfide quenching tower F is 375°C under the condition of pipeline insulation at 7bar;

[0045] The refluxed gaseous hydrogen sulfide 3 passes through the hydrogen sulfide liquefier G to obtain the refluxed liquid hydrogen sulfide 5, the temperature of the r...

Embodiment 2

[0050] Embodiment 2 A kind of aftertreatment method of hydrogen sulfide

[0051] The sulfur obtained from the quenching tower is discharged from the liquid sulfur discharge port L, and the discharged sulfur 6 is preheated to 100°C, and enters the hydrogen sulfide reactor A through the sulfur feed pipe C, and is mixed with hydrogen and passed through the catalytic tube to obtain Hydrogen sulfide synthesis gas 1, hydrogen sulfide synthesis gas 1 is discharged from hydrogen sulfide synthesis gas outlet B at 678.35kg / h (the composition of hydrogen sulfide synthesis gas 1 is 92.24% hydrogen sulfide, 7.41% sulfur, 0.35% impurities), and the output The material temperature is 378°C, 7bar. Under the condition of pipeline insulation and pressure preservation, the temperature when entering the hydrogen sulfide quenching tower F is 375°C;

[0052] The refluxed gaseous hydrogen sulfide 3 passes through the hydrogen sulfide liquefier G to obtain the refluxed liquid hydrogen sulfide 5, the ...

Embodiment 3

[0057] Embodiment 3 A kind of aftertreatment method of hydrogen sulfide

[0058] The sulfur obtained from the quenching tower is discharged from the liquid sulfur discharge port L, and the discharged sulfur 6 is preheated to 100°C, and enters the hydrogen sulfide reactor A through the sulfur feed pipe C, and is mixed with hydrogen and passed through the catalytic tube to obtain Hydrogen sulfide synthesis gas 1, hydrogen sulfide synthesis gas 1 is discharged from hydrogen sulfide synthesis gas outlet B at 678.35kg / h (the composition of hydrogen sulfide synthesis gas 1 is 92.24% hydrogen sulfide, 7.41% sulfur, 0.35% impurities), and the output The material temperature is 375°C, 4bar. Under the condition of pipeline insulation, the temperature when entering the hydrogen sulfide quenching tower F is 365°C;

[0059] The refluxed gaseous hydrogen sulfide 3 passes through the hydrogen sulfide liquefier G to obtain the refluxed liquid hydrogen sulfide 5, the temperature of the refluxe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com