Cyanogen chloride liquefaction and gas-liquid separation method

A technology of gas-liquid separation and gas-liquid separator, which is applied in the direction of separation methods, chemical instruments and methods, and dispersed particle separation, etc., which can solve the problems of small temperature interval, large amount of gasification, and more crystallization of the vessel wall, etc., so as to facilitate storage and the effect of measuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the purpose, technical solution and advantages of the present invention more clearly, the method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

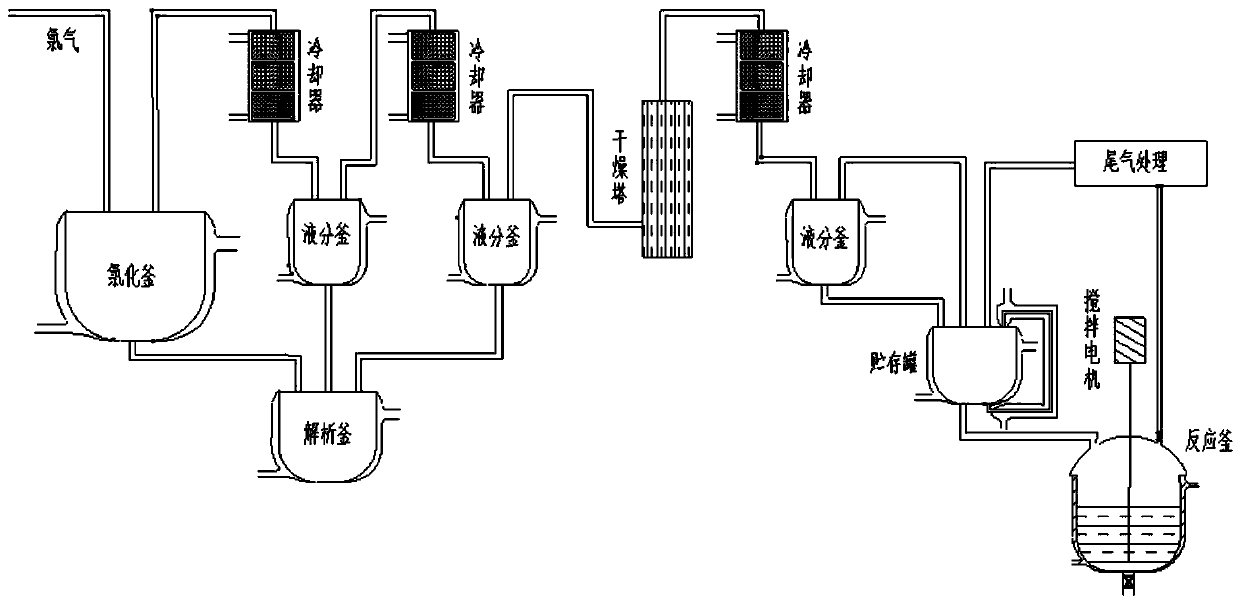

[0019] figure 1 It is the flowchart of the three-stage condensation-gas-liquid separation method of cyanogen chloride that the present invention is the present invention. Such as figure 1 Shown, the flow process of cyanogen chloride liquefaction and gas-liquid separation method of the present invention mainly comprises cyanogen chloride preparation, primary condensation, primary gas-liquid separation, secondary condensation, secondary gas-liquid separation, drying, tertiary condensation and The three-stage gas-liquid separation can also include the storage process of cyanogen chloride. Specific steps are as follows:

[0020] (1) Chlorine and sodium cyanide react in the chlorination reactor to prepare cyanogen chloride. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com