Vehicle-mounted carbon dioxide phase change circulating refrigerating system, circulating method and vehicle-mounted refrigerator

A refrigeration system, carbon dioxide technology, applied in gas cycle refrigerators, refrigeration and liquefaction, refrigerators, etc., can solve the problems of small COP value, power and energy occupied by battery life, and limited energy of vehicle battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

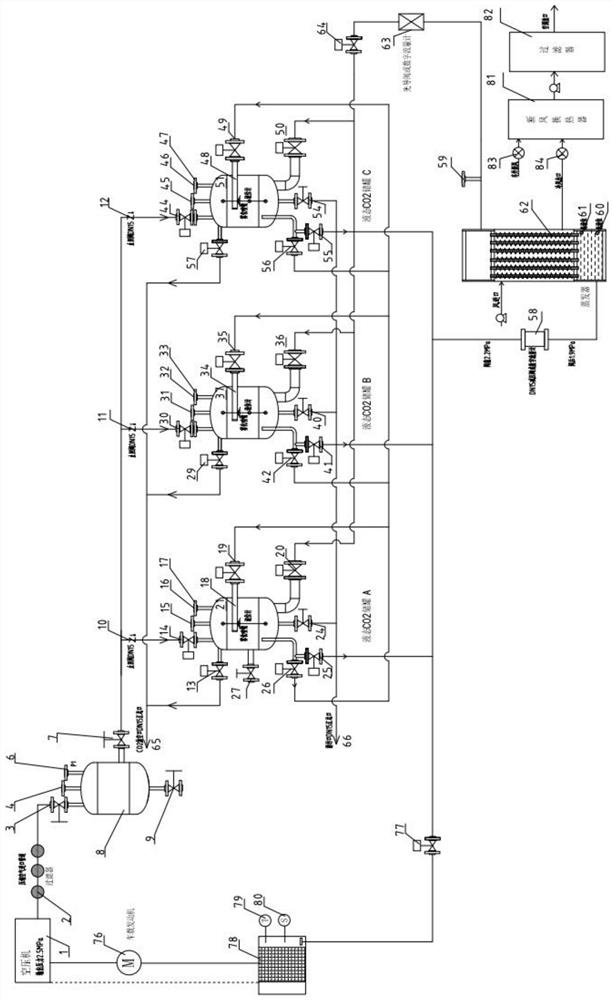

[0103] see figure 1 As shown, this embodiment provides a vehicle-mounted carbon dioxide phase-change cycle refrigeration system, which mainly includes a battery compartment group 78, a vehicle-mounted engine 76, an air compressor 1, and at least two parallel arrangements of liquid CO 2 Storage tank and an evaporator 62.

[0104] read on figure 1 In the vehicle-mounted carbon dioxide phase-change cycle refrigeration system shown, the battery compartment group 78 used is used to provide energy for the vehicle; the vehicle-mounted engine 76 used is used to provide power for the vehicle and the air compressor 1; The press 1 is connected with the vehicle-mounted engine 76 or the battery compartment group 78, and is used to provide high-pressure gas for the system driven by the vehicle-mounted engine 76 or the battery compartment group 78; liquid CO 2 The storage tank can be 2 A and B in parallel, or three A, B and C in parallel, liquid CO 2 The storage tanks are respectively con...

Embodiment 2

[0131] Based on the vehicle-mounted carbon dioxide phase change cycle refrigeration system in embodiment 1, this embodiment provides a carbon dioxide phase change and gas expansion refrigeration, gas pressure change and temperature drop liquefaction cycle refrigeration method, including steps:

[0132] S1, filling the first storage tank A with liquid carbon dioxide that can be used in a single cycle, and filling a small amount of liquid carbon dioxide into the second storage tank B and the third storage tank C;

[0133] S2, the air compressor 1 is driven by the vehicle-mounted engine 76 or the air compressor 1 is directly driven by the battery compartment group 78, and the high-pressure air is fed into the first storage tank A, the second storage tank B and the third storage tank C respectively, and respectively Keep the pressure in the first storage tank A at 25kg / cm 2 , the pressure in the second storage tank B is not lower than 10kg / cm2 , and the pressure in the third stora...

Embodiment 3

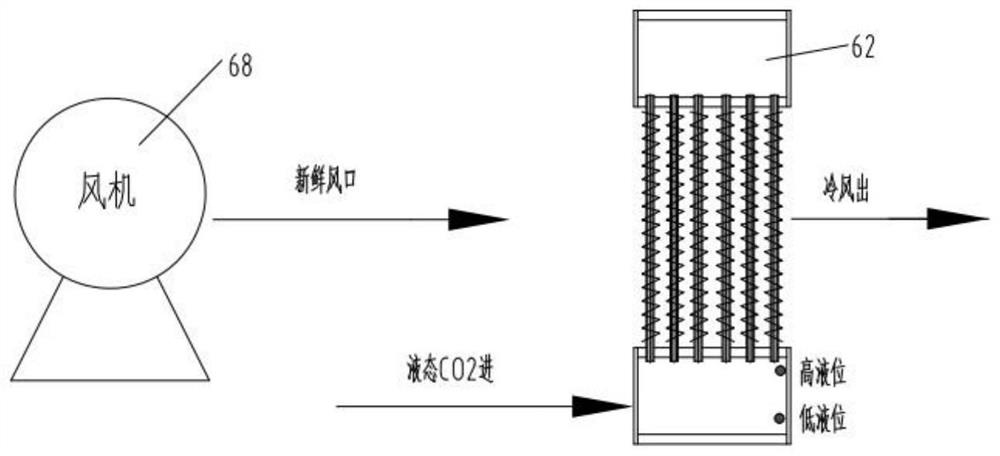

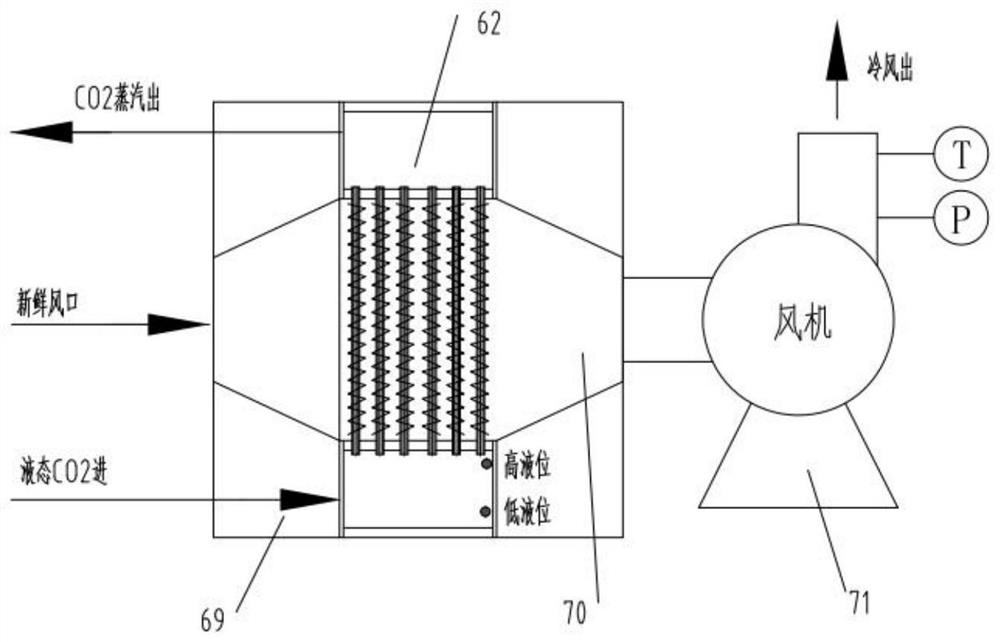

[0144] Such as figure 2 and Figure 5 As shown, different from the above-mentioned embodiment 1, this embodiment provides a vehicle-mounted refrigeration system using the vehicle-mounted carbon dioxide phase-change cycle refrigeration system. The vehicle-mounted refrigeration system also includes a first fresh air blower 68, and the first fresh air blower 68 is arranged At the inlet of the brine of the evaporator 62 , the brine is air, which flows through the outside of the tube wall of the evaporator 62 .

[0145] In this embodiment, the temperature control of the brine at the brine outlet of the evaporator 62 can be achieved by feeding liquid CO 2 High pressure gas control liquid CO from storage tank A / B / C 2 The pressure in tank A / B / C regulates the flow of liquid CO through evaporator 62 2 the quality of. The liquid CO flowing through the evaporator 62 can also be adjusted by a pressure reducing valve or a flow meter 58. 2 the quality of. It is also possible to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com