Oilfield associated gas complete liquefaction recovery system and method thereof

A technology of oilfield associated gas and recovery system, applied in the field of oilfield associated gas full liquefaction recovery system, can solve the problems of high investment cost and huge equipment, and achieve the effects of high resource recovery rate, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

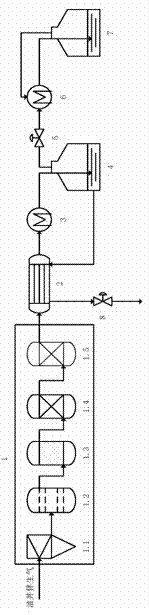

[0015] Such as figure 1 As shown, the oilfield associated gas full liquefaction recovery system includes associated gas pretreatment device 1, regenerator 2, first condenser 3, gas-liquid separator 4, throttle valve 5, second condenser 6, LNG storage tank 7, regulating valve 8, associated gas pretreatment device 1 includes sequentially connected oil removal device 1.1, dust removal and purification device 1.2, acid gas removal device 1.3, dehydration device 1.4, adsorption and separation nitrogen device 1.5, and regenerator 2 The light hydrocarbon outlet is connected to the regulating valve 8, and the lower part of the gas-liquid separator 4 is connected to the light hydrocarbon inlet of the regenerator 2.

[0016] The LNG storage tank 7 and the second condenser 6 form a loop. The dust removal and purification device 1.2 uses a combination of cyclone separator, wire mesh and hollow fiber filter element according to the cleanliness of the air source, or only uses the wire mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com