Method for recycling copper foils and aluminum foils in waste lithium ion batteries

A lithium-ion battery and copper foil technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of low efficiency, complicated process, high cost, etc., and achieve adjustment and optimization, mature technology, and rich experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

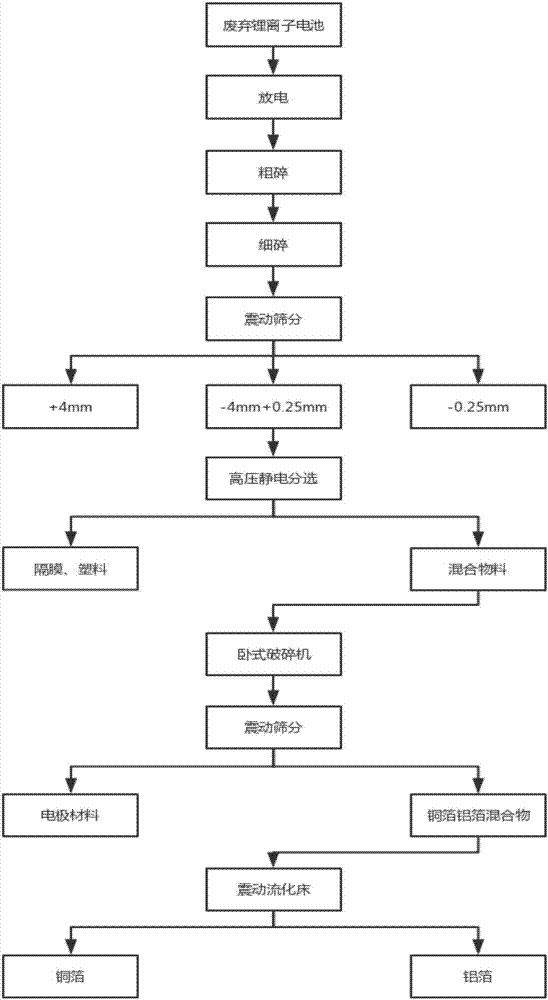

[0018] Please refer to figure 1 Shown, it has shown a kind of method for reclaiming copper foil and aluminum foil in the waste lithium ion battery of preferred embodiment of the present invention, comprises the following steps:

[0019] (1) Put the discharged waste lithium-ion battery into the roller crusher and vertical impact crusher, and put the product after two stages of crushing into the vibrating screen for screening and classification. The product is divided into three grades, Take the intermediate particle size; in this embodiment, when discharging, place the waste lithium-ion battery in a NaCl solution with a mass fraction of 5% and discharge it for 48 hours, and then carry out coarse crushing on the discharged lithium-ion battery through a roller crusher, and then coarsely crush The final product is finely crushed by a vertical screenless impact crusher, and the finely crushed product is screened by a vibrating screen, and the three particle sizes are +4mm, -4mm+0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com