Lost foam casting method

A lost foam casting and lost foam technology, applied in casting molding equipment, molds, mold components, etc., can solve the problems of environmental pollution, increase production costs, etc., and achieve the goal of improving quality, saving energy, and improving environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

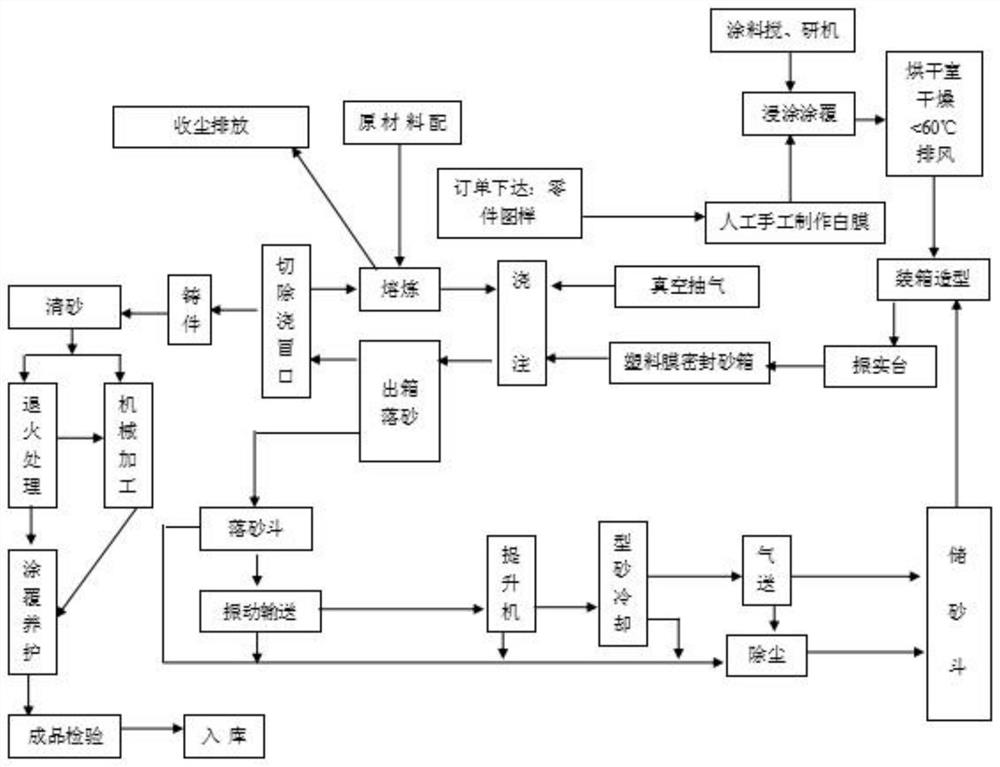

[0027] see figure 1 , the present invention provides a technical solution: a lost foam casting method, including drawing drawing of lost foam, mold making, molding sand molding, vibration, sealing and vacuuming treatment, mold shell elimination, mold pouring, exhaust gas purification treatment, casting post-production Treatment and sand recovery, the specific steps of lost foam casting are:

[0028] (1) The lost foam includes the sand box and the mold shell. After the order is placed, the part pattern is drawn, and then the white film is manually produced according to the part pattern. The paint is stirred and ground by the paint stirring and grinding machine, and then applied on the outside of the white film model. On the surface, foam and silica sol are used to make the mold shell according to the shape and size of the casting. The mold shell includes multiple cavities, and the mold shell is placed in a drying room for drying. The temperature is controlled below 60 degrees a...

Embodiment 2

[0044] see figure 1 , the present invention provides a technical solution: a lost foam casting method, including drawing drawing of lost foam, mold making, molding sand molding, vibration, sealing and vacuuming treatment, mold shell elimination, mold pouring, exhaust gas purification treatment, casting post-production Treatment and sand recovery, the specific steps of lost foam casting are:

[0045] (1) The lost foam includes the sand box and the mold shell. After the order is placed, the part pattern is drawn, and then the white film is manually produced according to the part pattern. The paint is stirred and ground by the paint stirring and grinding machine, and then applied on the outside of the white film model. On the surface, foam and silica sol are used to make the mold shell according to the shape and size of the casting. The mold shell includes multiple cavities, and the mold shell is placed in a drying room for drying. The temperature is controlled below 60 degrees a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com