Device for preparing liquefied natural gas with pipeline pressure energy and application method thereof

A technology for liquefied natural gas and pipeline pressure, applied in the field of equipment for preparing liquefied natural gas, can solve problems such as difficult guarantee, blockage of liquefaction equipment, high liquefaction rate, etc., and achieve the effect of low cost, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

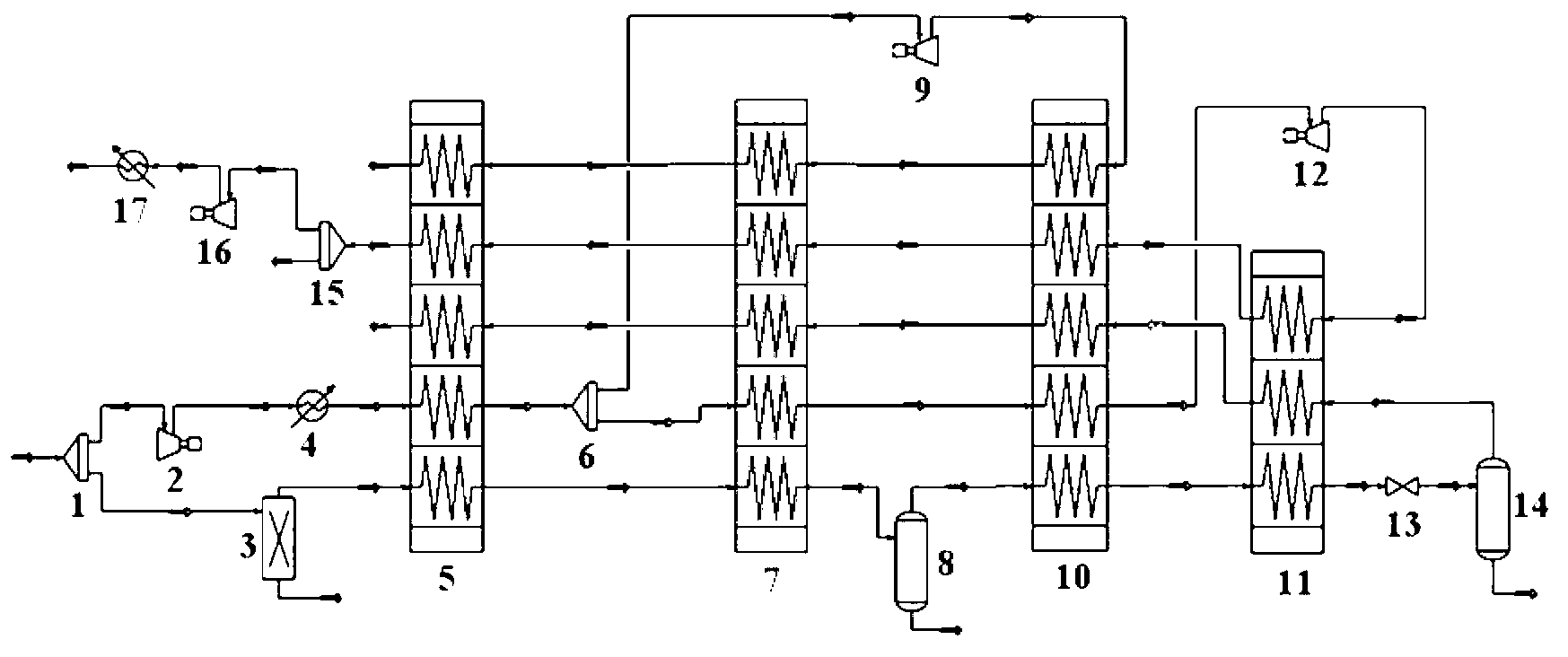

[0029] This embodiment relates to a device for preparing liquefied natural gas by using pipeline pressure energy. Heater 5, second-stage splitter 6, second-stage heat exchanger 7, heavy hydrocarbon separator 8, first-stage expander 9, third-stage heat exchanger 10, fourth-stage heat exchanger 11, second A first-stage expander 12, a throttle valve 13, a gas-liquid separator 14, a third-stage flow divider 15, a second-stage supercharger 16, and a second-stage water cooler 17, the structure of which is as follows figure 1 Shown:

[0030] This embodiment also relates to a method for preparing liquefied natural gas using the aforementioned device, the method comprising the following steps:

[0031] Step 1, divide the molar composition into 95% CH 4 and 5%N 2 Natural gas with a pressure of 4 MPa, a temperature of 15°C and a flow rate of 1 kmol / h passes through the first stage splitter 1 to form the first line and the second line. The volume percentage of the natural gas entering ...

Embodiment 2

[0038] This embodiment relates to a device for preparing liquefied natural gas by using pipeline pressure energy. Heater 5, second-stage splitter 6, second-stage heat exchanger 7, heavy hydrocarbon separator 8, first-stage expander 9, third-stage heat exchanger 10, fourth-stage heat exchanger 11, second A first-stage expander 12, a throttle valve 13, a gas-liquid separator 14, a third-stage flow divider 15, a second-stage supercharger 16, and a second-stage water cooler 17, the structure of which is as follows figure 1 Shown:

[0039] This embodiment also relates to a method for preparing liquefied natural gas using the aforementioned device, the method comprising the following steps:

[0040] Step 1, divide the molar composition into 95% CH 4 and 5%N 2 , natural gas with a pressure of 4 MPa, a temperature of 15°C, and a flow rate of 1 kmol / h passes through the first-stage splitter 1 to form the first line and the second line. The volume percentage of the natural gas enteri...

Embodiment 3

[0047] This embodiment relates to a device for preparing liquefied natural gas by using pipeline pressure energy. Heater 5, second-stage splitter 6, second-stage heat exchanger 7, heavy hydrocarbon separator 8, first-stage expander 9, third-stage heat exchanger 10, fourth-stage heat exchanger 11, second A first-stage expander 12, a throttle valve 13, a gas-liquid separator 14, a third-stage flow divider 15, a second-stage supercharger 16, and a second-stage water cooler 17, the structure of which is as follows figure 1 Shown:

[0048] This embodiment also relates to a method for preparing liquefied natural gas using the aforementioned device, the method comprising the following steps:

[0049] Step 1, divide the molar composition into 90% CH 4 and 10%N 2 , natural gas with a pressure of 5 MPa, a temperature of 15°C, and a flow rate of 1 kmol / h passes through the first-stage splitter 1 to form the first line and the second line. The volume percentage of the natural gas enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com