Liquefying and purifying device for chlorine in electrolytic magnesium chloride

A technology of magnesium chloride and chlorine gas, applied in liquefaction, electrolysis components, electrolysis process, etc., to achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

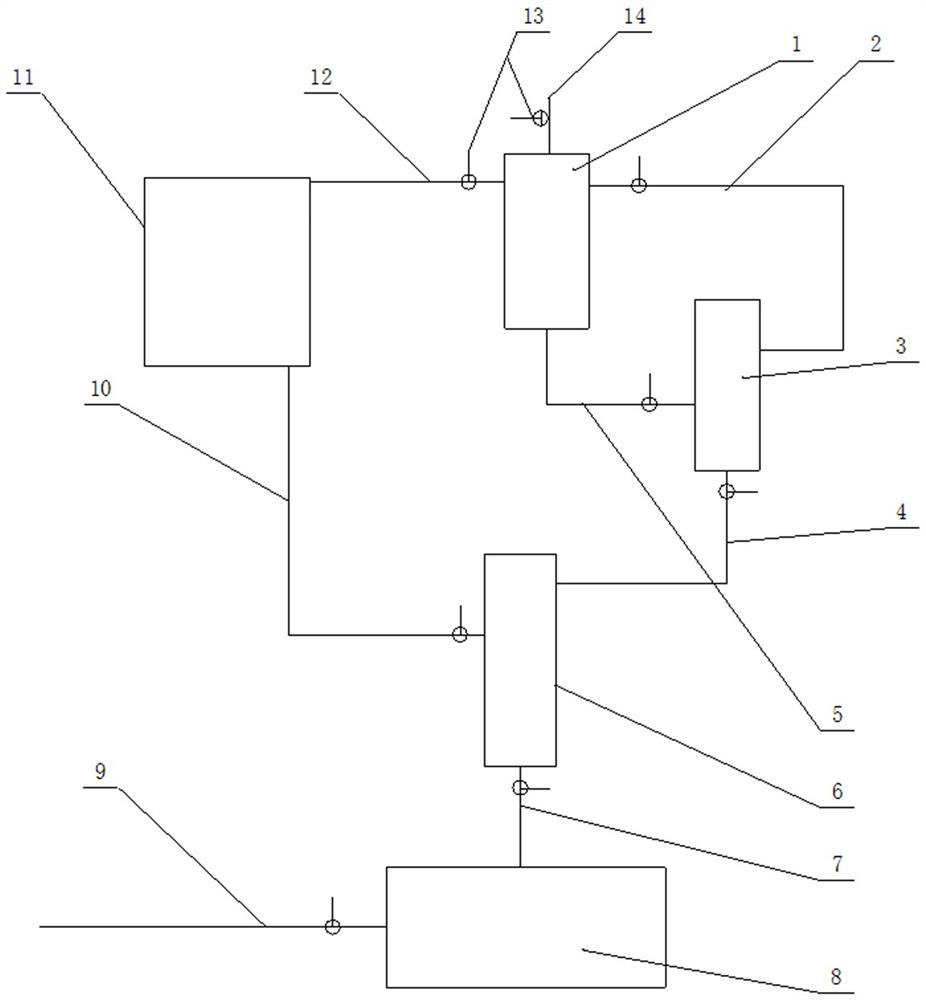

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing, but should not be interpreted as that the scope of the subject matter of the present invention is limited to following embodiment, under the situation of not departing from above-mentioned technical idea of the present invention, all according to the common technical knowledge of this field and Various modifications, substitutions and alterations made by conventional means are included within the scope of the present invention.

[0019] Such as figure 1 As shown, the device for liquefaction and purification of chlorine in electrolytic magnesium chloride consists of liquefier 1, pipeline A2, gas-liquid separator 3, pipeline B4, pipeline C5, liquid chlorine storage tank 6, pipeline D7, intermediate tank 8, and pipeline E9 , pipeline F10, tail gas treatment tank 11, pipeline G12, chlorine gas inlet pipe 14 and valve 13;

[0020] A chlorine inlet pipe 14 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com