Method for separating and recovering gallium in gallium arsenide sludge

A technology for separation and recovery of gallium arsenide, applied in the field of hydrometallurgy, can solve the problems of difficult removal, high energy consumption, and difficult recovery, and achieve the effects of low cost, simple equipment and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

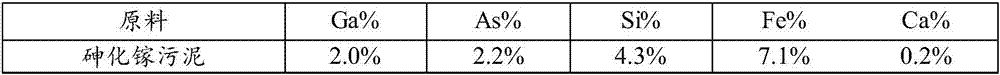

[0056] The gallium arsenide sludge used in Example 1 has a moisture content of 55%, and the main components are shown in Table 1.

[0057] Table 1 Main components of gallium arsenide sludge used in Example 1

[0058]

[0059] (1) Slurry alkaline leaching: Weigh 222.2g of gallium arsenide sludge (water content of 55%, dry weight of 100g) and 477.8g of water into a 2L beaker (solid-liquid ratio 1:6), turn on the stirring, Slurry at a speed of 1 / min for 2h, then add 180g of sodium hydroxide solid, heat to 90°C, react for 3h, add another 300g of water, continue the heat preservation reaction for 1h, and filter to obtain 750mL leachate.

[0060] Sampling is sent for inspection, and ICP-MS is used to detect Ga, As, Si, Fe, and Ca in the above-mentioned leaching solution. The results are as follows: the gallium content in the leaching solution is 2.637g / L, the arsenic content is 2.659g / L, the silicon content is 5.328g / L, the iron content is 1mg / L, and the calcium content is 10mg / L; calcula...

Embodiment 2

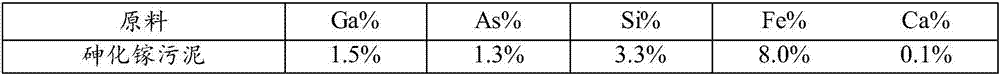

[0068] The water content of the gallium arsenide sludge used in Example 2 is 52%, and the main components are shown in Table 2.

[0069] Table 2 Main components of gallium arsenide sludge used in Example 2

[0070]

[0071] (1) Slurry alkali leaching: Weigh 208.4g gallium arsenide sludge (water content 52%, dry weight 100g) and 491.6g water into a 2L beaker (solid-liquid ratio 1:6), turn on the stirring, At a speed of 1 / min, the slurry was slurried for 1.5h, then 210g of sodium hydroxide solid was added, heated to 85°C, after 3h of reaction, 300g of water was added, the reaction was kept for 1h, and filtered to obtain 760mL of leachate.

[0072] Sampling is sent for inspection, and ICP-MS is used to detect Ga, As, Si, Fe, and Ca in the above-mentioned leaching solution. The results are as follows: the gallium content in the leaching solution is 1.944g / L, the arsenic content is 1.704g / L, the silicon content is 4.333g / L, the iron content is 2mg / L, and the calcium content is 12mg / L; ca...

Embodiment 3

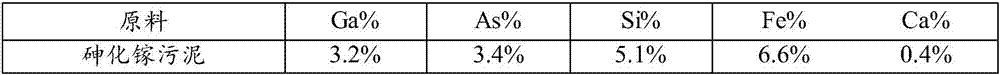

[0080] The moisture content of the gallium arsenide sludge used in Example 3 is 59%, and the main components are shown in Table 3.

[0081] Table 3 Main components of gallium arsenide sludge used in Example 3

[0082]

[0083] (1) Slurry alkaline leaching: Weigh 243.9g gallium arsenide sludge (59% moisture content, 100g dry weight) and 456.1g water into a 2L beaker (solid-liquid ratio 1:6), turn on the stirring, Slurry for 1h at a rotation speed of 1h / min, then add 240g of sodium hydroxide solid, heat to 80°C, react for 4h, add 300g of water, continue to keep the reaction for 1h, and filter to obtain 740mL leachate.

[0084] Sampling is sent for inspection, and ICP-MS is used to detect Ga, As, Si, Fe, and Ca in the above-mentioned leaching solution. The results are as follows: the gallium content in the leaching solution is 4.285g / L, the arsenic content is 4.544g / L, the silicon content is 6.786g / L, the iron content is 3mg / L, and the calcium content is 14mg / L; calculated, the gallium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com