Preparation method for magnetic biological carbon by one-step synthesis

A biochar, magnetic technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of high cost, cumbersome process, etc., and achieve remarkable effect, simplified process and convenient preparation. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

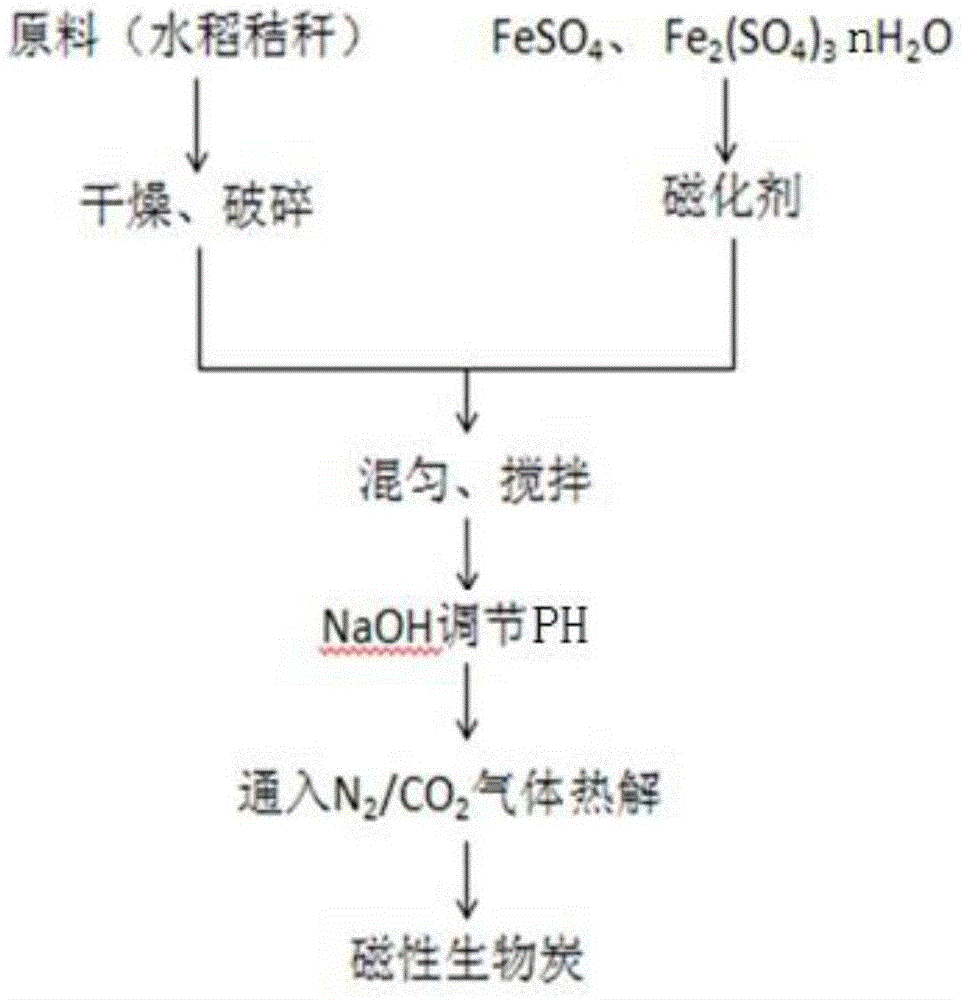

Method used

Image

Examples

Embodiment 1

[0026] The biomass raw material is air-dried under natural conditions and stored for later use. The biomass raw material is crushed into a length of about 2 cm, and the dried and crushed biomass raw material is added to the 2+ and Fe 3+ In the iron salt solution, in the iron salt solution, Fe 2+ The molar concentration of Fe is 0.4mol / L, Fe 3+ The molar concentration of the mixture is 0.04mol / L, and the mixed solution is obtained after adding the biomass raw material into the iron salt solution, and the weight percentage of the biomass raw material in the mixed solution is 0.03%.

[0027] Iron salt solution is formed by mixing divalent iron salt solution and ferric salt solution,

[0028] The ferrous salt solution is obtained by adding FeSO 4 Soluble in deionized water.

[0029] The ferric salt solution is obtained in the following way: Fe 2 (SO 4 ) 3 -nH 2 O is dissolved in deionized water.

[0030] The ferrous salt solution and the ferric salt solution are mixed to ...

Embodiment 2

[0036] After the biomass raw material is air-dried under natural conditions, it is stored for later use. The biomass raw material is crushed into a length of about 4 cm, and the dried and crushed biomass raw material is added to the 2+ and Fe 3+ In the iron salt solution, in the iron salt solution, Fe 2+ The molar concentration of Fe is 0.6mol / L, Fe 3+ The molar concentration is 0.06mol / L, and the mixed solution is obtained after adding the biomass raw material into the iron salt solution, and the weight percentage of the biomass raw material in the mixed solution is 0.05%.

[0037] Iron salt solution is formed by mixing divalent iron salt solution and ferric salt solution,

[0038] The ferrous salt solution is obtained by adding FeSO 4 Soluble in deionized water.

[0039] The ferric salt solution is obtained in the following way: Fe 2 (SO 4 ) 3 -nH 2 O is dissolved in deionized water.

[0040] The ferrous salt solution and the ferric salt solution are mixed to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic saturation | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com