Method for comprehensively recovering zinc nickel cadmium from copper cadmium residues

A zinc-nickel-cadmium and copper-cadmium slag technology, applied in the field of nickel, cadmium, and zinc recovery, can solve the problems of large chemical consumption, harsh conditions, low metal purity, etc., to reduce equipment input costs, low costs, and metal recovery. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

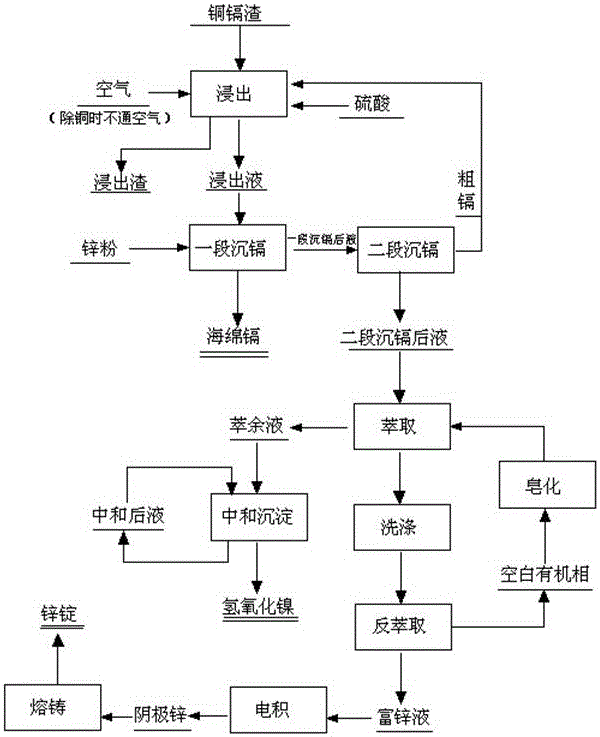

[0029] Embodiment 1: according to figure 1 Operate as shown.

[0030] The chemical composition of a typical copper-cadmium slag is shown in Table 1.

[0031] Table 1 Chemical composition of a typical copper-cadmium slag, unit: %

[0032] Cu Zn Cd Ni Fe Pb sn 1.72 4.61 22.28 0.67 0.67 4.23 0.27

[0033] A. Leaching

[0034] Add water to copper-cadmium slag according to the liquid-solid ratio of 4~5 / 1 to make slurry, blow in air, add concentrated sulfuric acid, adjust the pH value of the leaching end point to 4.0~5.0, stop the oxygen after 2 hours of oxidation reaction, and add step C The crude cadmium obtained in the second stage of cadmium precipitation replaces copper, and 1.5 times the theoretical amount is added. After a reaction time of 1 hour, samples are taken for Cu and Fe tests. After passing the test, the leachate is obtained by filtration. The components of the leachate are: Cu 0.064g / L, Fe 0.0012g / L, Zn 7.03g / L, Cd 50.0g / L, Ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com