Method for separating and extracting vanadium and chromium from vanadium slag sodium-modified roasting water leachate

A technology of sodium roasting and leaching solution, which is applied in the direction of improving process efficiency, can solve the problems of difficulty in recycling, inability to process, and difficult, avoid high-risk solid waste and high-burden treatment wastewater, realize recycling, The effect of reducing alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 4L of vanadium slag sodium roasting water leaching solution containing V 30g / L, Cr 1.1g / L, pass into carbon dioxide to adjust the pH value of the leaching solution to 8.5, and then follow the NH 3 Add ammonium carbonate to 1 times the molar ratio of V and stir at room temperature for 3 hours, then filter and separate to obtain ammonium meta-acid crystals and filtrate A, and the recovery rate of vanadium is 78%; ammonium meta-acid is calcined at 500° C. for 2 h to obtain vanadium-containing 99.3% Vanadium oxide products, wherein the content of Cr is 0.03%.

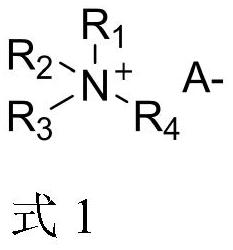

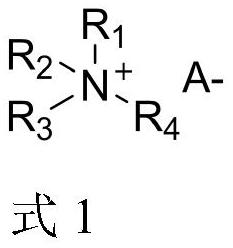

[0045] Filtrate A and composition are 40% methyltrialkyl extractant (in formula 1, R 1 ~R 3 for C 8 ~C 10 straight-chain alkane group, R 4 for CH 3 , A - for CO 3 2- ) + 20% 2-octanol + 40% sulfonated kerosene (volume percent) organic phases were mixed, and then 3-stage countercurrent extraction was carried out under the condition that the flow ratio was 1:10 to obtain raffinate A1 and loaded organic pha...

Embodiment 2

[0048] Take 3L of vanadium slag sodium roasting water leaching solution containing V 30g / L, Cr 13g / L, pass into carbon dioxide to adjust the pH value of the leaching solution to 7.5, and then follow the NH 3 0.8 times of the / V mol ratio was added ammonium bicarbonate and stirred at 60° C. for 0.5 h, during which the pH of the solution was added to control the pH of the solution at about 8.0, and then filtered and separated to obtain ammonium meta-acid crystals and filtrate A, and the rate of recovery of vanadium was 61%; The ammonium acid was calcined at 500°C for 2 hours to obtain a vanadium pentoxide product containing 99.2% of vanadium, in which the content of Cr was 0.05%.

[0049] Filtrate A and composition are 5% methyl trioctyl extractant (in formula 1, R 1 ~R 3 is n-octyl; R 4 for CH 3 ;A - for CO 3 2- )+10% 2-octanol+85% aviation kerosene (volume percent) organic phases were mixed, and then 8 stages of countercurrent extraction were carried out under the condit...

Embodiment 3

[0052] Get 2L containing V 80g / L, Cr 40g / L vanadium slag sodium roasting water leachate, and then according to NH 3 0.6 times of / V mol ratio is added liquid ammonia, and feeds carbon dioxide to adjust the pH value of the leaching solution to be 9.5, stir at room temperature for 2h, then filter and separate to obtain ammonium meta-acid crystals and filtrate A, the recovery rate of vanadium is 49%; ammonium meta-acid is in Calcined at 500°C for 2 hours to obtain a vanadium pentoxide product containing 99.1% of vanadium, wherein the content of Cr is 0.07%.

[0053] Filtrate A and composition are 10% methyl trinonyl extractant (in formula 1, R 1 ~R 3 is n-nonyl, R 4 for CH 3 ;A - for CO 3 2- ) + 10% tridecanol + 80% No. 200 solvent naphtha (volume percentage) mixed with the organic phase, and then carry out 14 stages of countercurrent extraction under the condition that the flow ratio is 1:4 to obtain the raffinate A1 and the loaded organic phase B1 . After washing the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com