Preparation method of magnetic biochar material

A biochar, magnetic technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of unsatisfactory heavy metal ion adsorption and secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

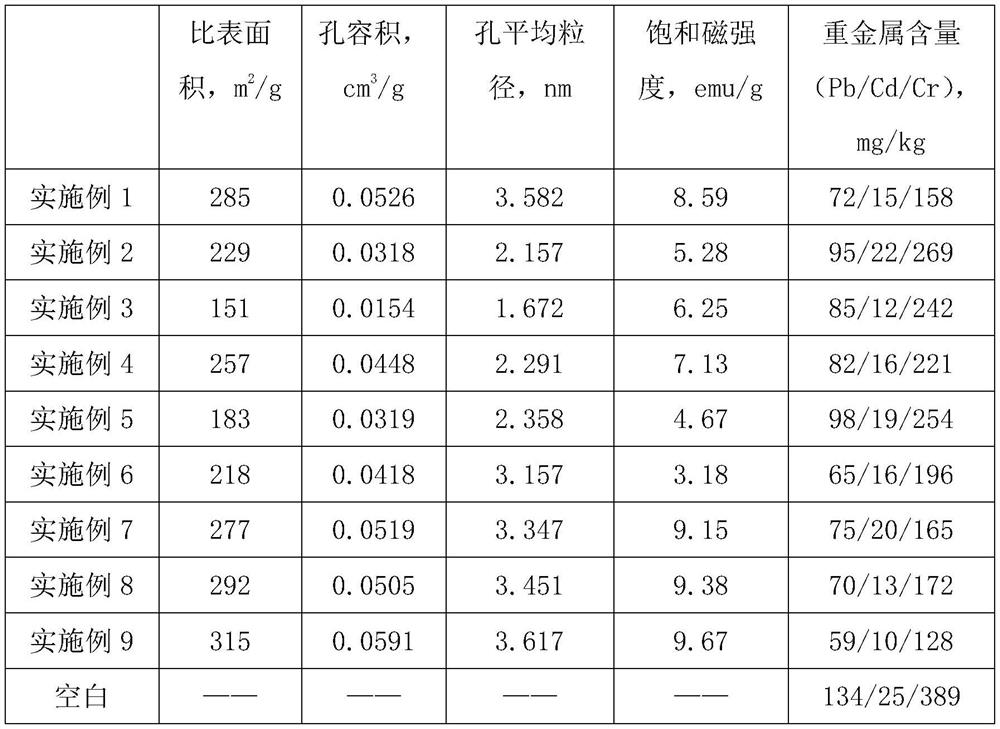

Examples

preparation example Construction

[0023] As one of the embodiments of the present invention, a method for preparing a magnetic biochar material comprises the following steps: using crop straw as a raw material, after pretreatment, sequentially impregnating with iron salt, freeze-drying, high-temperature pyrolysis, and post-treatment to obtain the Magnetic biochar materials.

[0024] Preferably, the pretreatment of the crop straws specifically includes: the crop straws are washed and preliminarily crushed, then heated and soaked in an alkaline solution, washed and dried, crushed and sieved.

[0025] Preferably, the crop stalks are washed and preliminarily crushed to a length less than 5 cm, then placed in a sodium carbonate solution with a mass fraction of 5-10% at 50-80° C. for 10-60 minutes, heated and soaked for 10-60 minutes, and then taken out to dry.

[0026] Before iron salt impregnation, the use of alkaline solution to heat and impregnate the crop straw has the following effects: on the one hand, it can...

Embodiment 1

[0037] (1) Raw material pretreatment: take corn stalks as raw materials, wash and dry them, and then crush them to a length of less than 5 cm, then place them in a sodium carbonate solution with a mass fraction of 5%, heat them to 80°C, soak them at a constant temperature for 30 minutes, and take them out to dry Dry;

[0038] (2) Ferric salt impregnation: take ferric chloride and ferrous chloride, be dissolved in water according to the ratio of 1:2 according to molar ratio and prepare the ferric salt mixed solution that the total concentration of iron ions is 1.5mol / L, will pass through step ( 1) The pretreated crop stalks are soaked in the iron salt mixed solution for 24 hours, then taken out and aired until the water content is 20%;

[0039] (3) Freeze-drying: vacuum freeze-dry the crop stalks impregnated in step (2), grind and pulverize them, the freeze-drying temperature is -20°C, the vacuum degree is 5 Pa, and the freeze-drying time is 20 minutes;

[0040] (4) Place the cr...

Embodiment 2

[0042] With embodiment 1, difference is, omit the mass fraction in the step (1) and be the sodium carbonate solution heating soaking step of 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com