Full-automatic washing machine

A fully automatic washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of cross-infection of laundry, affecting the washing effect of clothes, etc., and achieve the effects of avoiding cross-infection, saving washing costs, and using hygienic use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

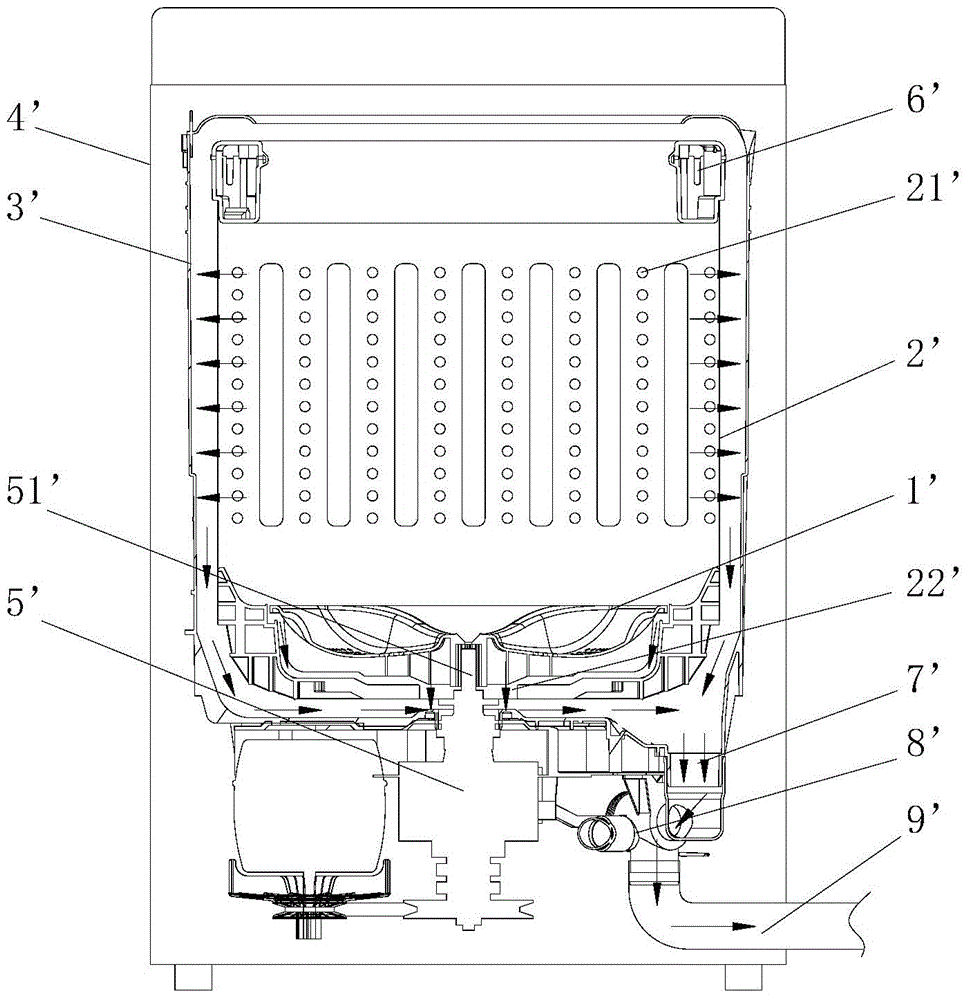

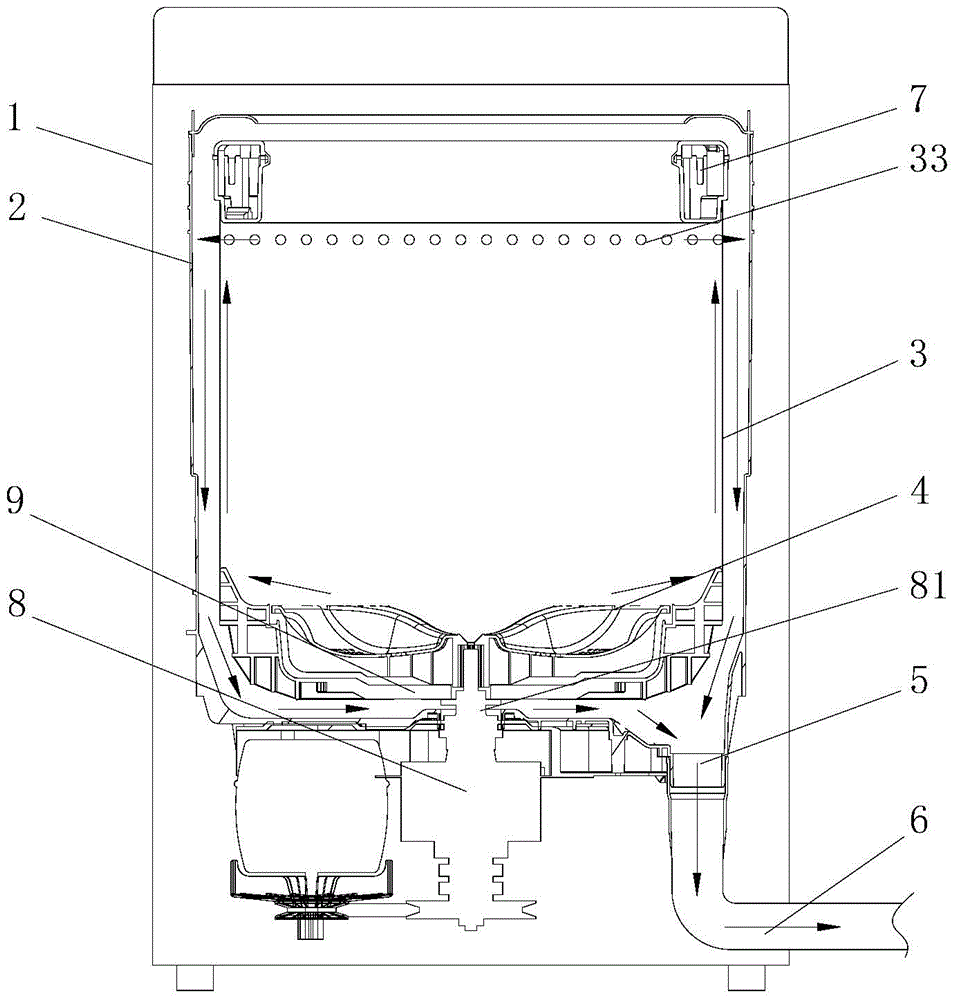

Embodiment 1

[0051] Such as Figure 4 As shown, the water outlet hole 33 described in this embodiment is located in the area between the lower edge of the balance ring 7 on the barrel body 31 and the position where the maximum water intake of the washing machine is set.

Embodiment 2

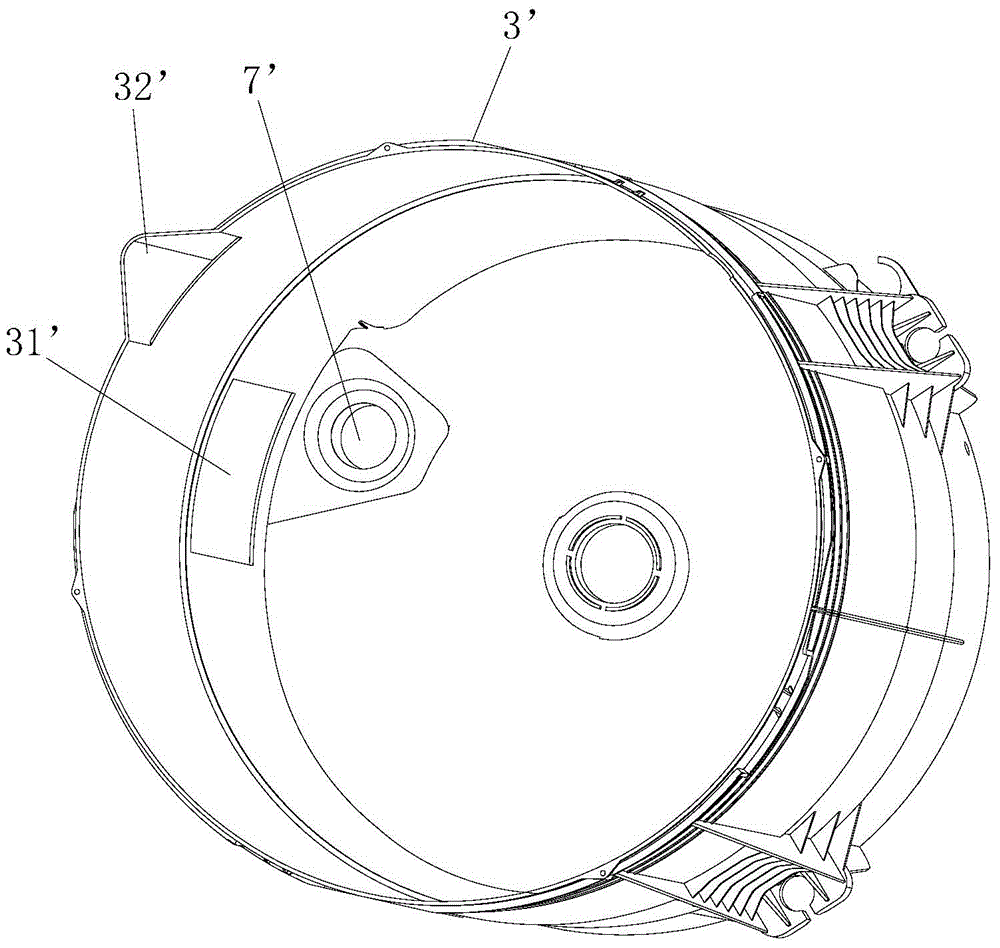

[0053] Such as Figure 5 As shown, the bucket body 31 of the present invention is provided with a drainage waterway structure for supplying water from the bottom 32 of the inner bucket to the upper water outlet hole 33 .

[0054] The barrel body 31 described in this embodiment has a rounded platform structure with a thick top and a thin bottom. The peripheral wall of the barrel body 31 and the axis of the inner barrel have an inclined angle α, and the included angle α is not greater than 4°; preferably 1°-2°. The barrel body 31 below the balance ring is provided with one circle or multiple circles of water outlet holes 33 arranged up and down.

Embodiment 3

[0056] Such as Figure 6 As shown, the difference between this embodiment and the above-mentioned second embodiment is that: the inner barrel body 31 is a cylindrical structure, and an outwardly protruding drainage groove 34 is provided on the barrel wall, and a water outlet 33 is located in each drainage groove 34 top. The opening of the drainage groove 34 faces the center of the barrel body 31, and the depth of the drainage groove 34 gradually deepens upwards from the bottom of the barrel body 31, that is, the bottom wall of the drainage groove and the inner barrel axis have an angle β inclined outwards, and the angle β 1°-2°.

[0057] Further, the side wall of the drainage groove 34 transitions smoothly with the surrounding wall of the barrel body 31 and the bottom of the drainage groove. Furthermore, the bottom end of the drainage groove 34 directly transitions smoothly with the surrounding wall of the barrel body 31 .

[0058] Preferably, the bottom of the drainage gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com