Washing machine inner barrel bottom seal structure

A technology of sealing structure and inner barrel bottom, applied in the field of washing machines, can solve the problems of affecting the washing effect of clothes, cross infection of laundry, etc., and achieve the effects of avoiding cross infection, improving sealing effect, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as Figure 4 As shown, the inner barrel bottom 1 described in this embodiment is of plastic structure, and the inner barrel flange 2 is of metal structure, which is directly embedded into the inner barrel bottom 1 by injection molding for sealing.

Embodiment 2

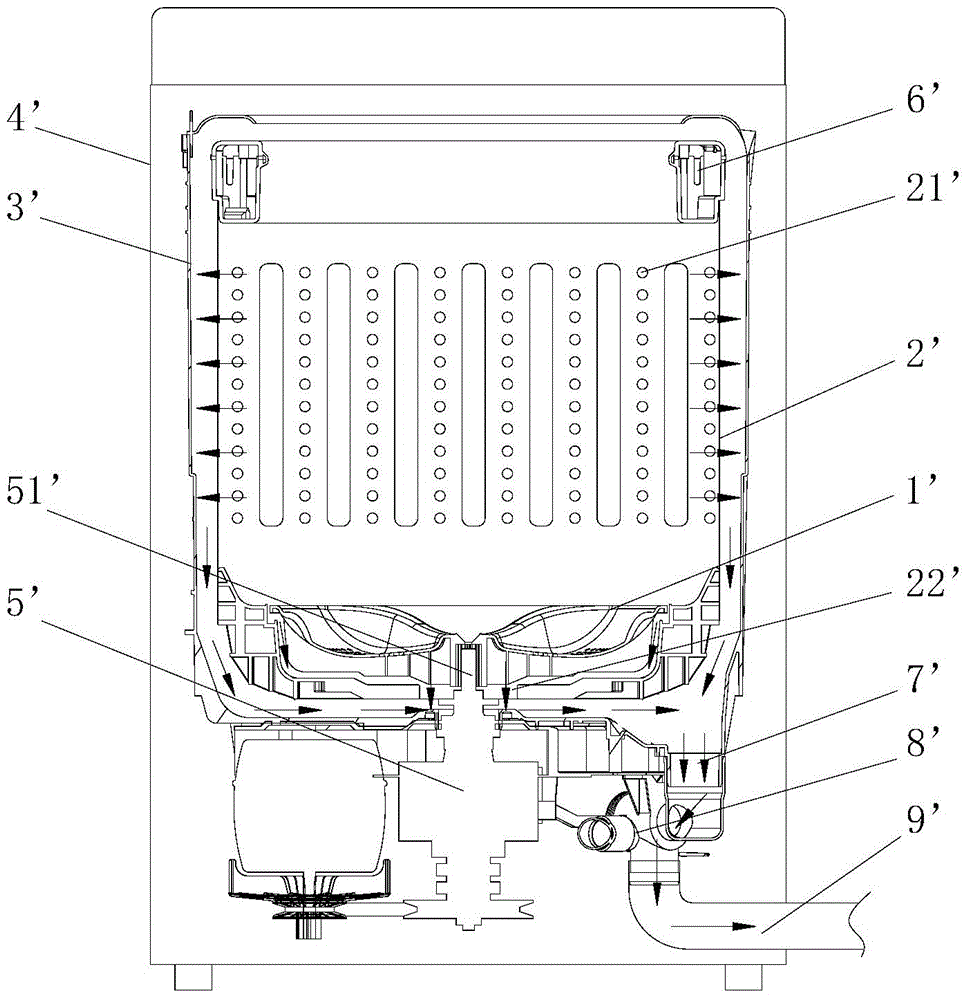

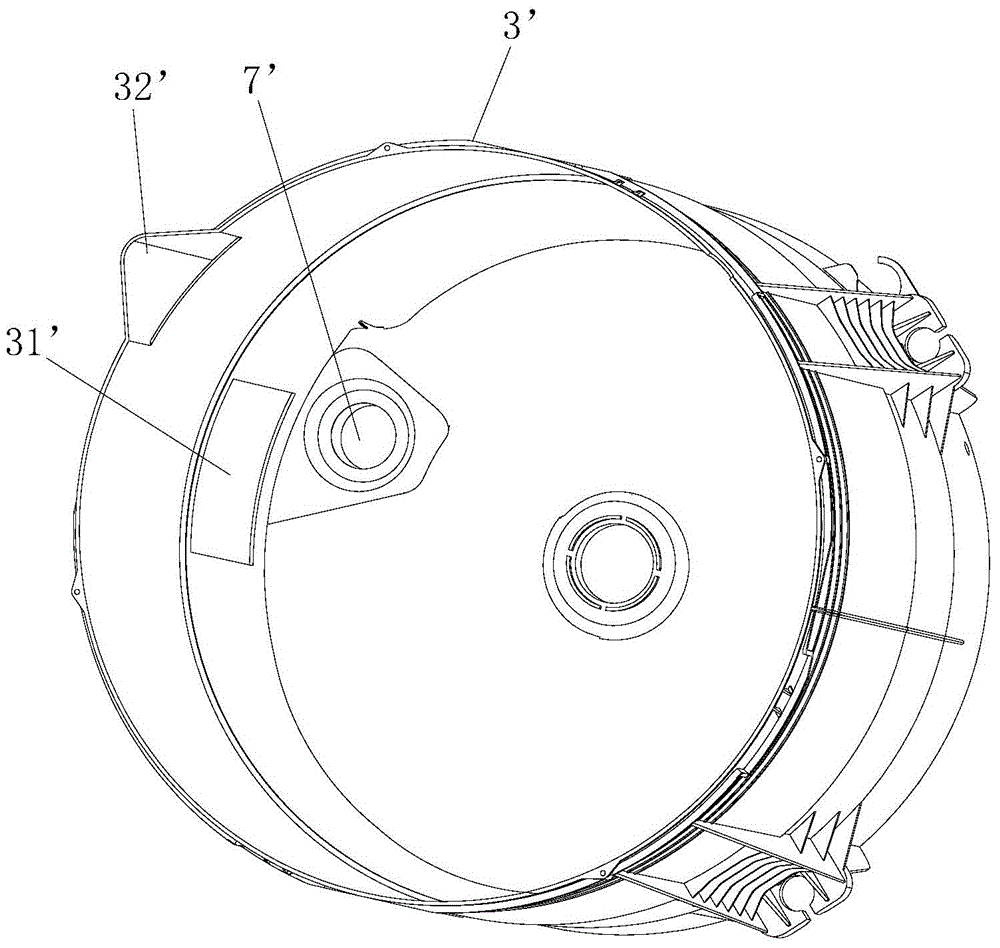

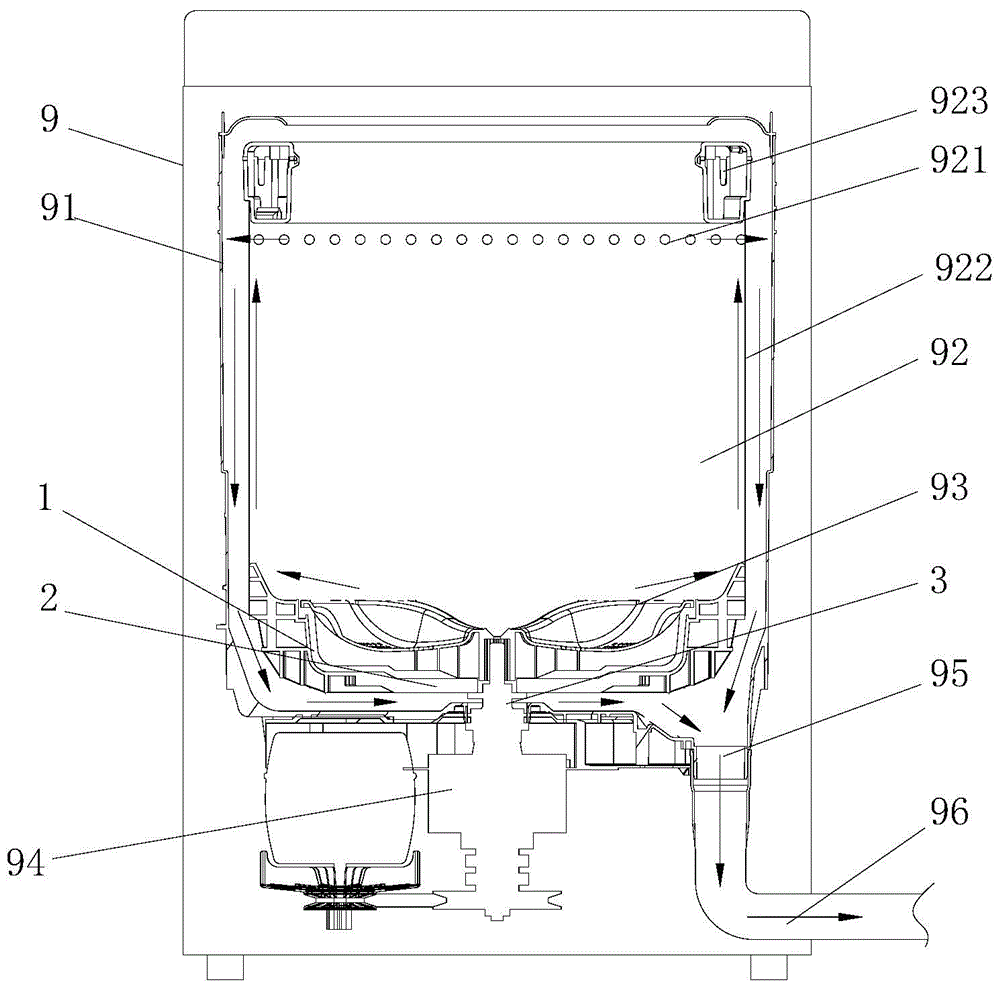

[0046] Such as Figure 5 to Figure 7 and Figure 14 to Figure 16 As shown, the inner barrel flange 2 described in this embodiment is installed below the inner barrel bottom 1, the center of the inner barrel bottom bottom wall 11 is a hollow portion 12, and the inner barrel flange 2 cooperates with the dehydration shaft 3 to block the hollow portion 12, and the inner barrel A sealing structure is provided between the flange 2 and the bottom wall 11 of the inner tub, and a sealing structure is provided between the dehydration shaft 3 and the flange 2 of the inner tub.

Embodiment 3

[0048] Such as Figure 5 and Figure 6 As shown, the inner barrel flange 2 and the inner barrel bottom wall 11 described in this embodiment are provided with a plurality of screw holes one by one, the inner barrel flange 2 is installed below the inner barrel bottom wall 11 through screws 4, and the inner barrel flange A first sealing ring 5 is sandwiched between the disc 2 and the bottom wall of the inner tub. A plurality of screw holes are located on the same circular track, and the first sealing ring 5 is located in the inner or outer area of the circular track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com