Method for improving cleaning rate and washing equipment

A technology for washing equipment and washing water, which is applied to cleaning equipment, washing machines/washing machines for tableware, and improving the efficiency of home appliances, etc., can solve the problems of low washing rate, large water consumption, low washing efficiency, etc. , The effect of reducing washing cost and improving washing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

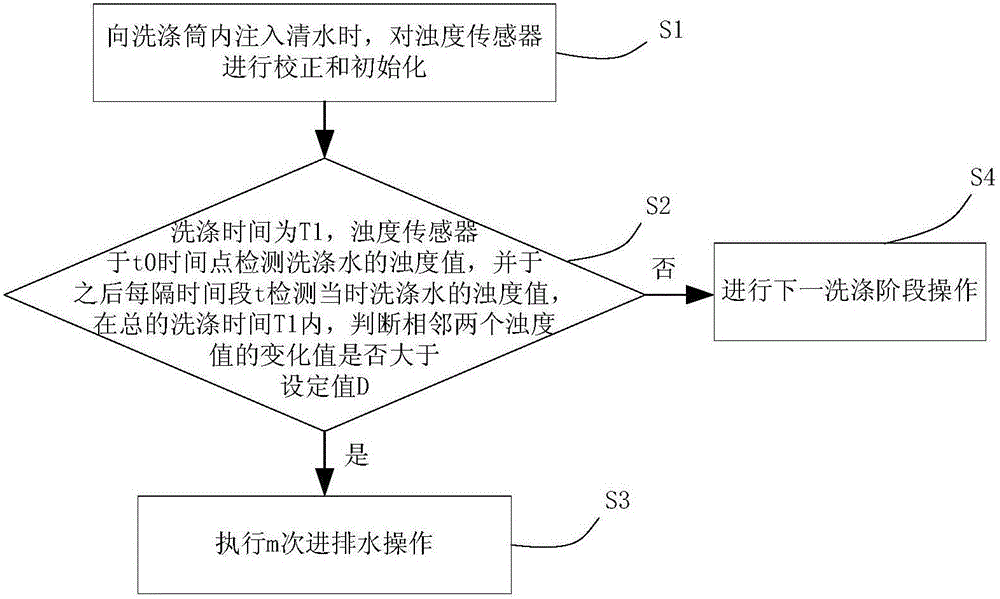

[0035] In order to solve the problems of large water consumption caused by the operation of the existing washing equipment without draining water in the washing process, the recycled use of polluted water, resulting in unclean washing of the products to be washed, low washing rate, and low washing efficiency, this embodiment provides A method to improve the cleaning rate, figure 1 It is a flow chart of a method for improving the cleaning rate provided in this embodiment. The method for improving the cleaning rate of this embodiment can be applied to washing equipment such as dishwashers or washing machines. During the washing process, the washing equipment can perform operations of draining dirty water and feeding clean water several times according to the washing stage and the turbidity of the washing water.

[0036] Take the application of the method for improving the washing rate in the dishwasher as an example, and the description is as follows:

[0037] The improvement c...

Embodiment 2

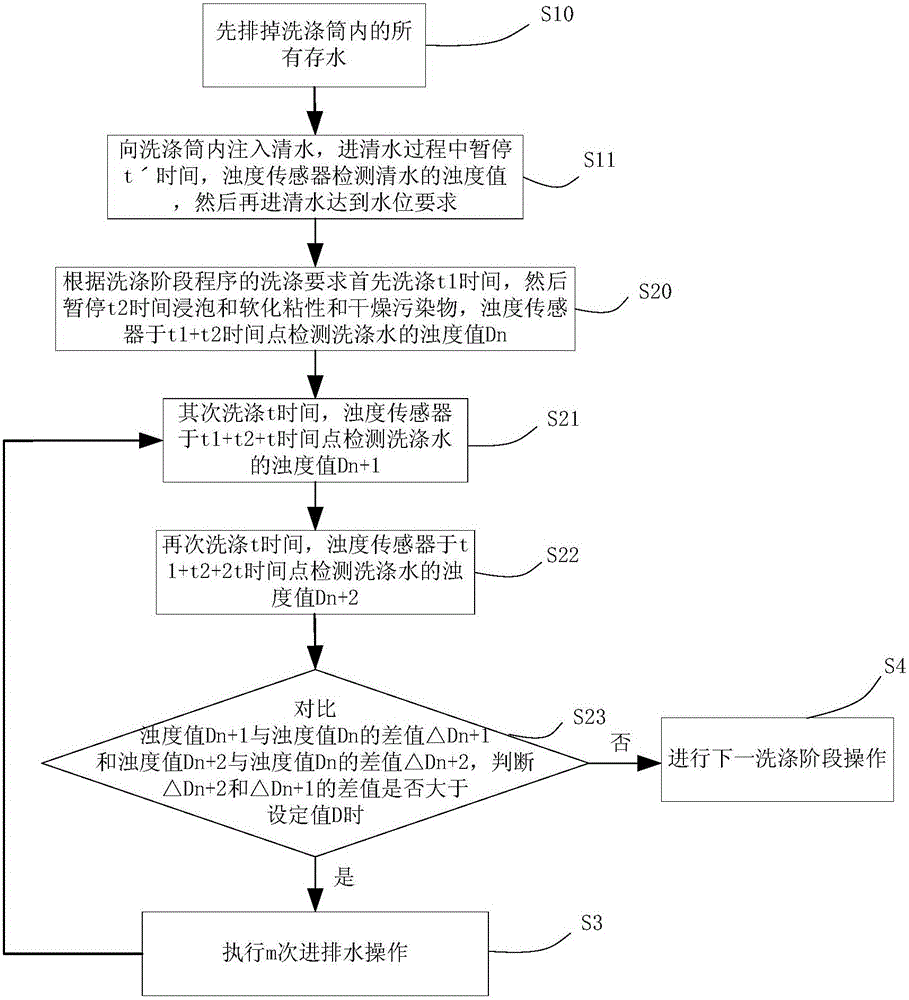

[0046] This embodiment proposes the second method for improving the cleaning rate, which is obtained by making slight improvements on the basis of the solution described in Example 1, such as figure 2 As shown, the method for improving the cleaning rate specifically includes the steps:

[0047] S10: In order to ensure that there is no water in the dishwasher, first drain all the water in the washing tub.

[0048] S11: Inject clean water into the washing tub, pause for tˊ time during the process of entering clean water, the turbidity sensor detects the turbidity value of the clean water, and then enter clean water to meet the water level requirement.

[0049] S20: According to the washing requirements of the washing stage program, first wash for t1 time, then pause for t2 time to soak and soften viscous and dry pollutants, and the turbidity sensor detects the turbidity value Dn of the washing water at the time point t1+t2, where t1+t2 The value of is equal to the value of t0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com