Torbanite washbox, coal separation system and coal separation method thereof

A coal jig and jig technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of inability to ensure the accuracy of heavy products, increase the basic links of the whole system, and inability to ensure light products, etc. Achieve the effect of reducing washing cost, improving system reliability and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

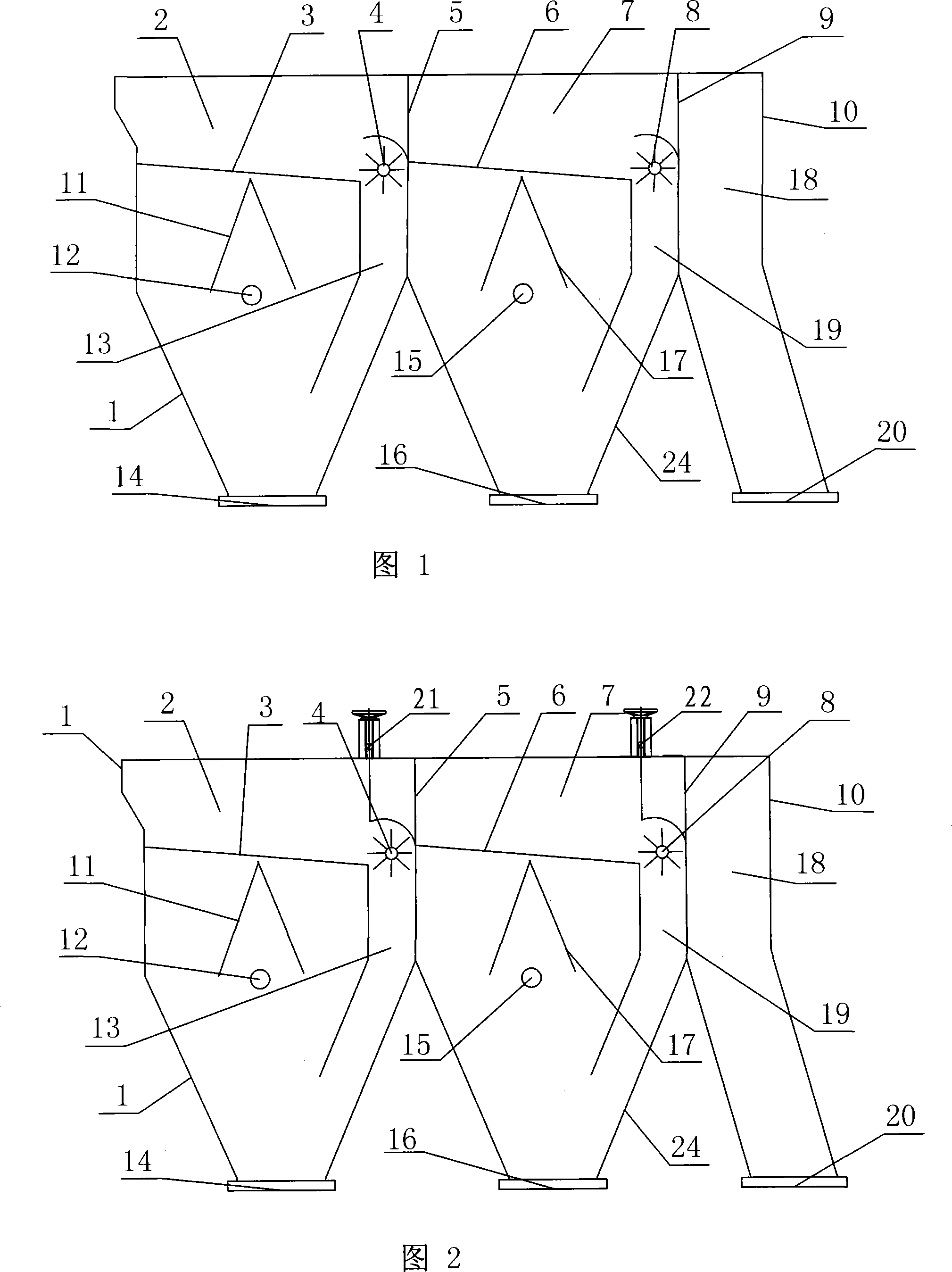

[0040] Embodiment 1, in FIG. 1 , a two-stage air chamber lump coal jig, which includes a common gangue section jig body 1 , an ordinary medium coal section jig body 24 and a clean coal discharge channel 10 . The inclination angle of the sieve plate 3 in the gangue section jig machine body 1 is several times larger than the inclination angle of the sieve plate of the common jig machine. The inclination angle of the sieve plate 6 of the mid-coal section in the body 24 of the mid-coal section jigger is several times larger than the inclination angle of the sieve plate of an ordinary jig. The inclination angle of the sieve plate 3 of the gangue section is larger than the inclination angle of the sieve plate 6 of the middle coal section. The height difference between the sieve plate surface at the outlet end of the gangue section and the sieve plate surface at the inlet end of the mid-coal section is kept between 50 and 700 mm. The clean coal discharge channel 10 is a closed devic...

Embodiment 2

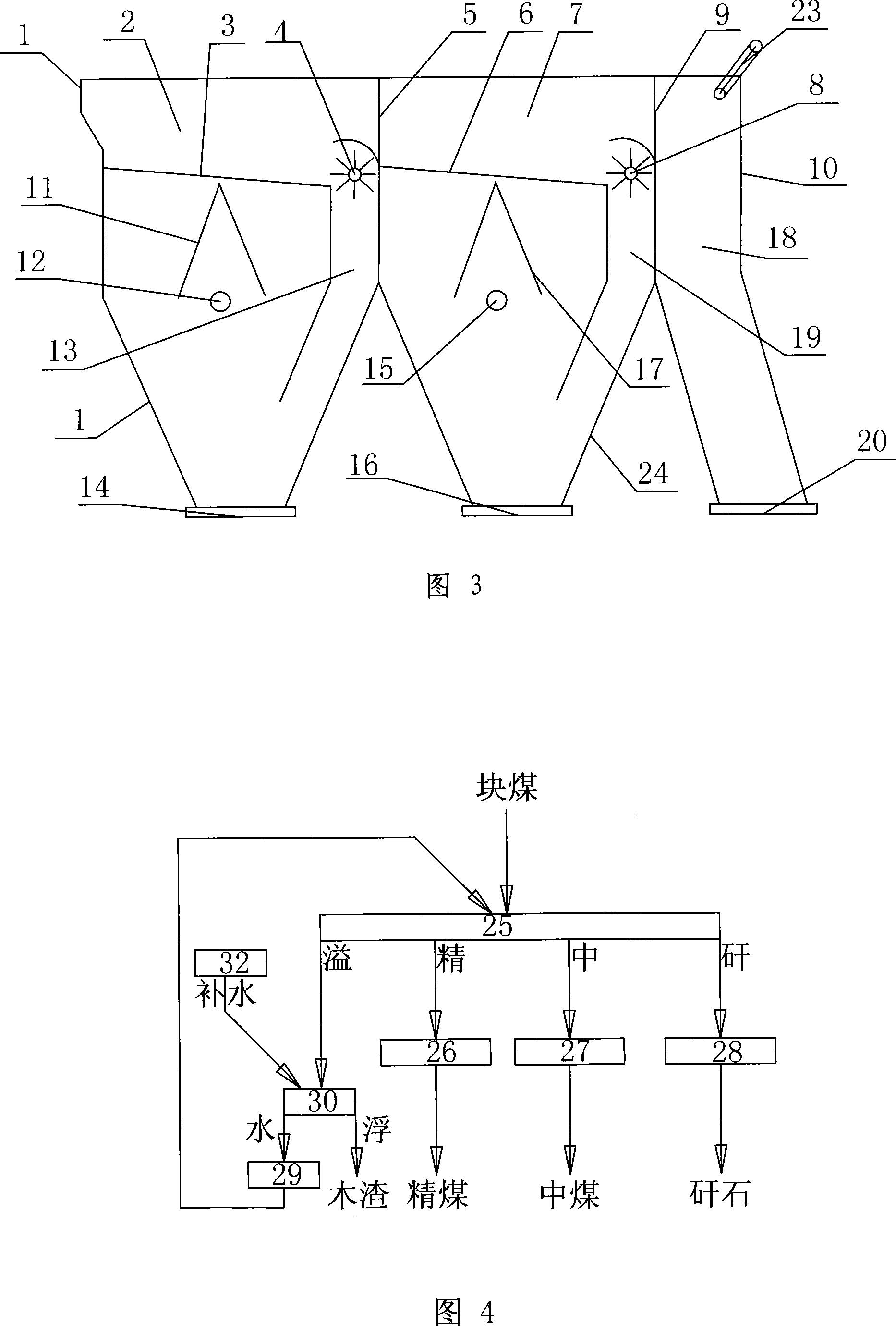

[0044] Embodiment 2, in Fig. 2, another kind of air chamber gangue jigging machine, the shape, structure, materials used, and functions of the gangue section jigging machine body 1 and the middle coal section jigging machine body 24 are as in the embodiment 1 described. The main shape, structure, materials used, and functions of the clean coal discharge channel 10 are also as described in Embodiment 1. The difference is that in FIG. 24 above the entrance of the gangue section gangue discharge device 4 and the mid-coal section discharge device 8, a gangue section discharge height adjustment device 21 and a mid-coal section discharge height adjustment device 22 that can adjust the discharge height are installed respectively.

[0045] When this embodiment is working, the working steps, methods, principles, etc. are as described in Embodiment 1, the difference is that through the adjustment of the installed gangue section discharge height adjustment device 21, which can adjust the...

Embodiment 3

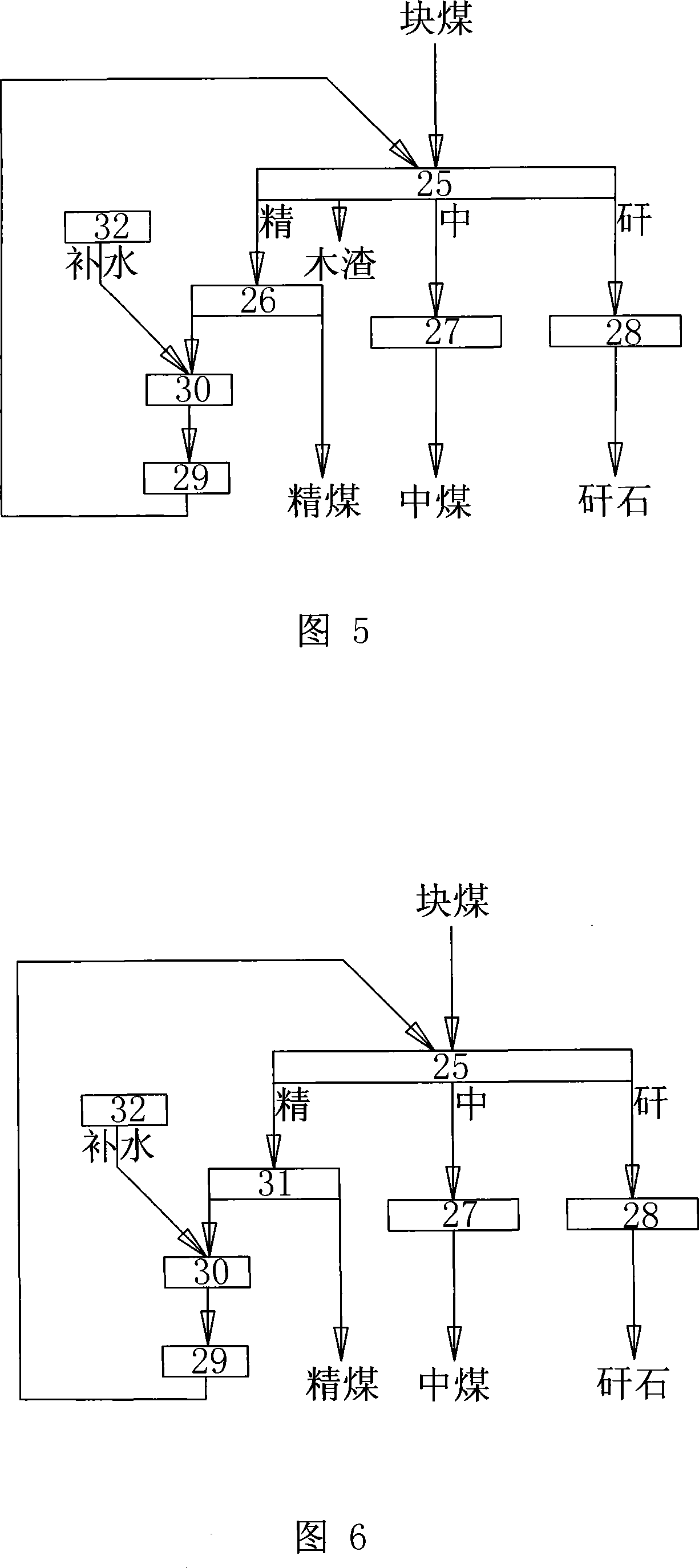

[0046] Embodiment 3, in Fig. 3, the third kind of air chamber lump coal jig, the shape, structure, materials used, and functions of the jig body 1 in the gangue section and the jig body 24 in the middle coal section are as in the embodiment 1 described. The main shape, structure, materials used, and functions of the clean coal discharge channel 10 are also as described in Embodiment 1, except that an automatic float discharge device 23 is installed on the clean coal discharge channel 10 .

[0047] Based on the same principle and method, the present invention can also realize the structure and function as shown in FIG. 2 on the lump coal jig machine as described in Embodiment 2.

[0048] When the present embodiment works, the working steps, methods, principles, etc. are as described in Embodiment 1, the difference is that the floating objects such as wood slag floating on the water surface are discharged by the installed floating object automatic discharge device 23.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com