Coarse slime separating system and method

A sorting system and technology for coarse coal slime, which are applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problem of the difficult operation of the sorting method, the low processing capacity of the cyclone, and the unsatisfactory sorting effect. and other problems, to achieve the effect of reducing the cost of coal preparation, reducing the cost of washing and reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

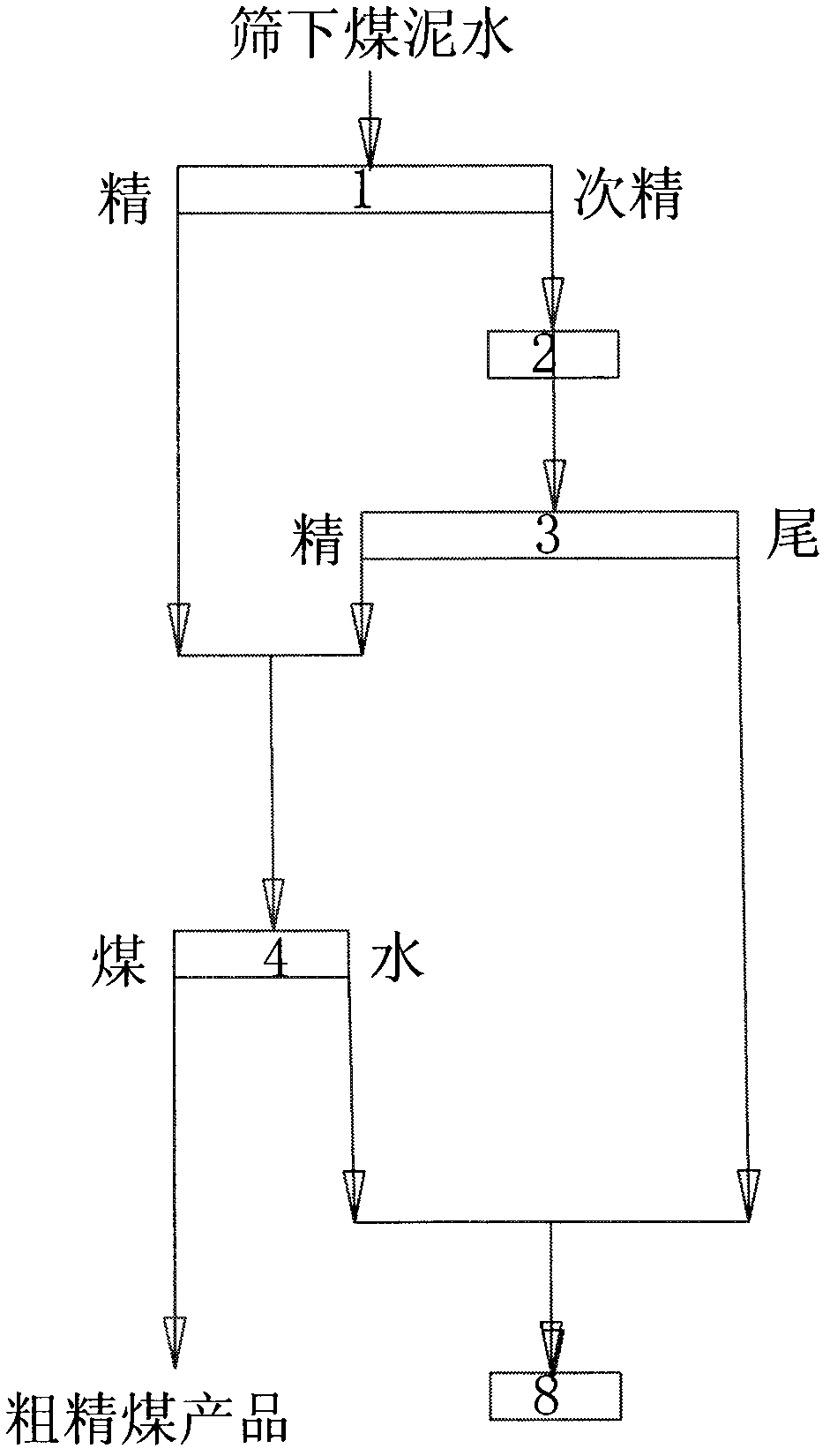

Embodiment 1

[0023] Example 1, figure 1 Among them, a kind of coarse coal slime separation system of the present invention, it comprises hydraulic separation device 1, feeding material pump 2, hydrocyclone 3, dehydration device 4, flotation device 8, wherein said feeding material pump 2 The feed inlet of the feed pump is connected with the underflow outlet of the hydraulic separation device 1 through a pipeline, and the discharge outlet of the feed pump 2 is connected with the feed inlet of the hydrocyclone 3 through a pipeline. The overflow port of the hydrocyclone 3 is connected with the feed port of the dehydration device 4 through a pipeline, and the overflow port of the hydraulic separation device 1 is also connected with the feed port of the dehydration device 4 through a pipeline, so The bottom flow port of the dehydration device 4 is connected with the feed port of the flotation device 8 through a pipeline, and the bottom flow port of the hydrocyclone 3 is connected with the feed p...

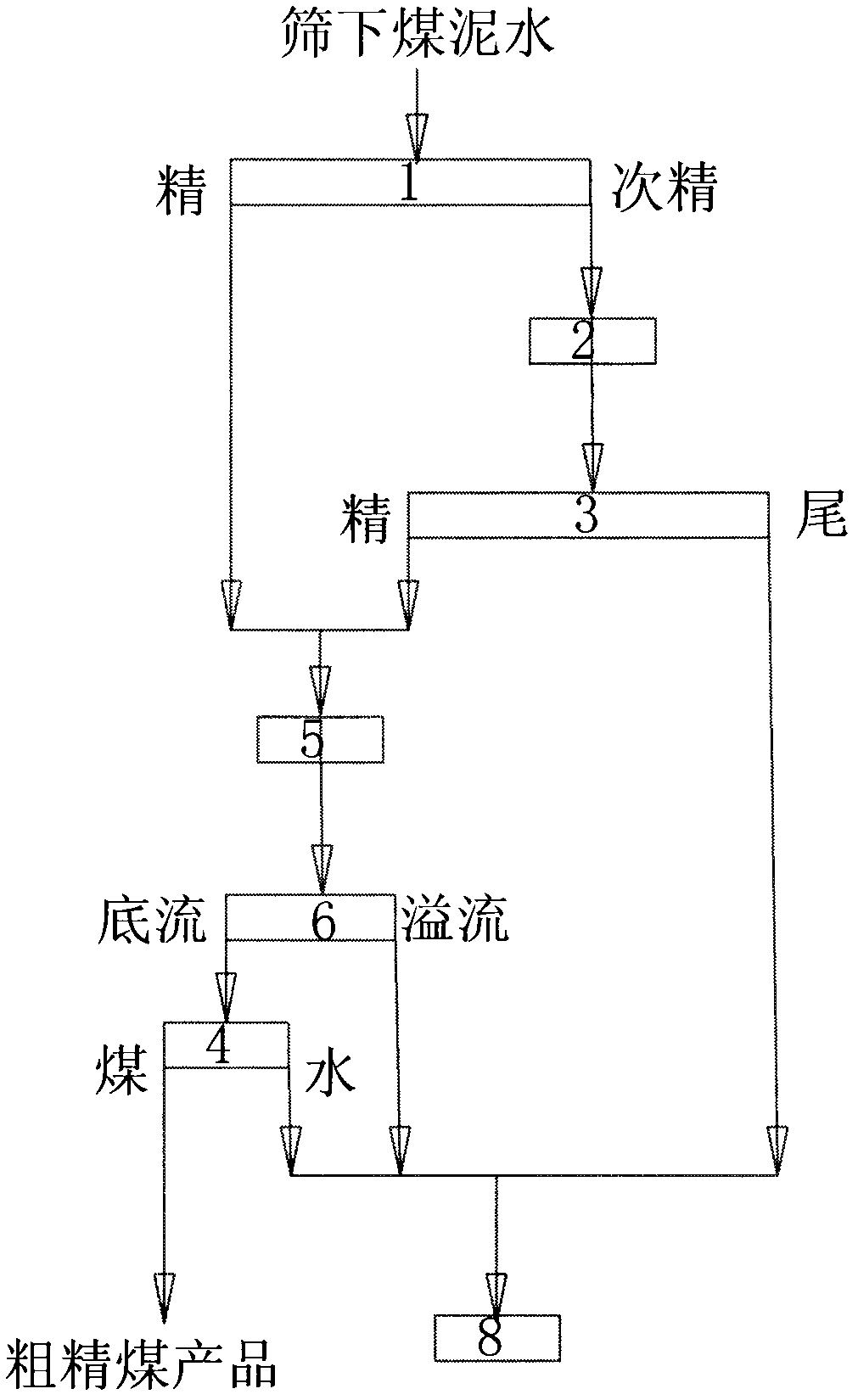

Embodiment 2

[0025] Example 2, in figure 2 Among them, another coarse coal slime separation system of the present invention, wherein the shape, structure, and Materials, effects, etc. are as described in Example 1. The difference is that a concentrated cyclone 6 and a concentrated feed pump 5 are added in front of the dehydration device 4 in the system, and the feed inlet of the concentrated feed pump 5 is connected with the hydraulic separation device 1 and the concentrated feed pump 5 through a pipeline. The overflow port of the hydrocyclone 3 is connected, the discharge port of the concentrated feed pump 5 is connected with the feed inlet of the concentrated cyclone 6 through a pipeline, and the bottom flow port of the concentrated cyclone 6 The feed port of the dehydration device 4 is connected through a pipeline, and the overflow port of the concentration cyclone 6 is connected with the feed port of the flotation device 8 through a pipeline.

[0026] When this embodiment is working...

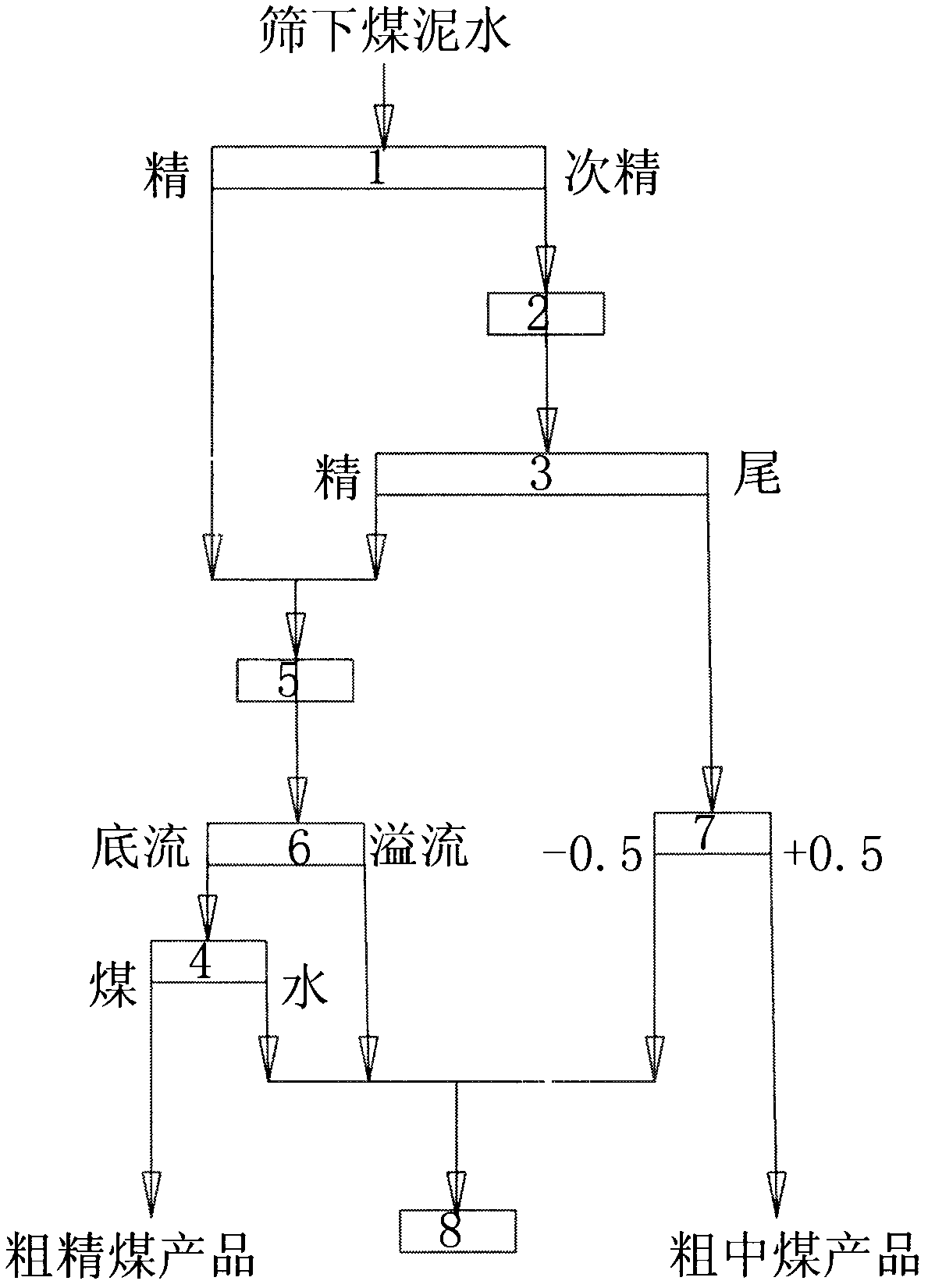

Embodiment 3

[0027] Example 3, in image 3 Among them, the third kind of coarse coal slime separation system, wherein the hydraulic separation device 1, feed pump 2, hydrocyclone 3, dehydration device 4, concentrated feed pump 5, concentrated cyclone 6, floating The shape, structure, material used, function, etc. of the selection device 8 are as described in Embodiment 2. The difference is that a classification device 7 is added between the bottom flow port of the hydrocyclone 3 and the flotation device 8 in the system, and the bottom flow of the classification device 7 passes through the pipeline and the feed of the flotation device 8. port connection. The classifying device 7 can be one of conventional technologies such as curved screen, linear screen, circular vibrating screen, electromagnetic screen, etc. in the prior art, or other equivalent alternative technologies and products.

[0028] When this embodiment is working, the working steps, methods, principles, etc. are as described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com