Gas turbine compressor washing device and method

A technology for gas turbines and water washing devices, which is applied to gas turbine devices, jet propulsion devices, components of pumping devices for elastic fluids, etc., can solve the problems of washing water consumption, reduce water consumption for washing, reduce production costs, shorten The effect of washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

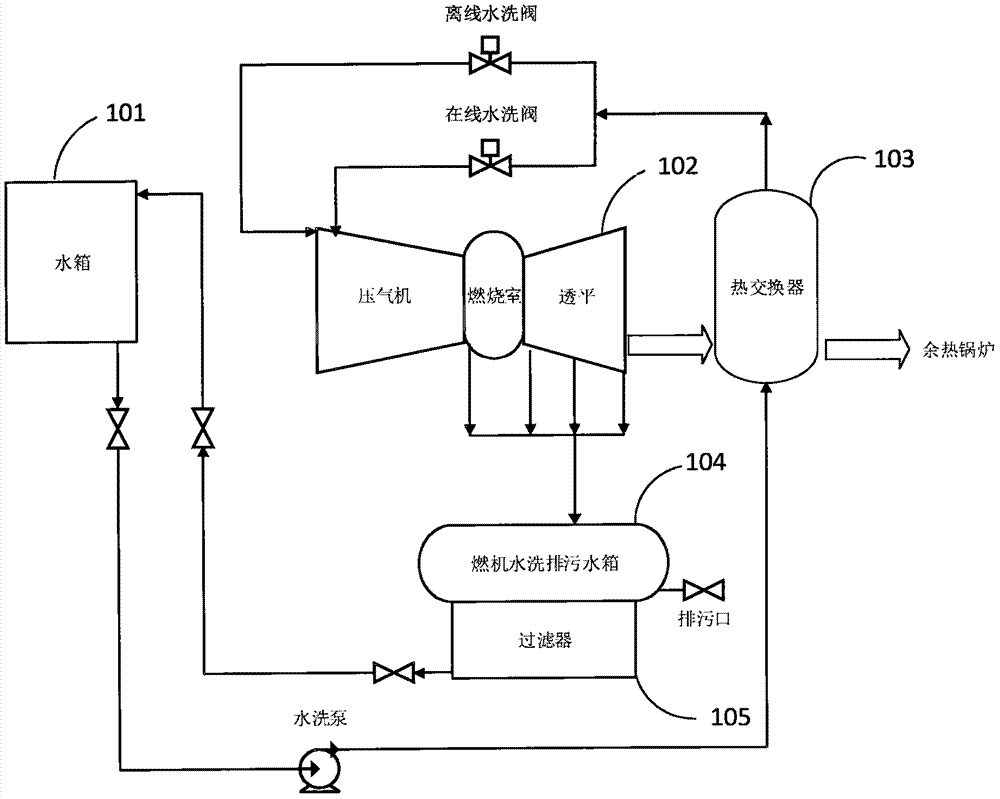

[0020] Taking a certain type of 360MW gas turbine as the application object, the block diagram of the gas turbine, the entire water washing device and its method is as follows figure 1 shown, with figure 1 Mark 101 is the compressor washing water tank, 103 is the heat exchanger, 104 is the gas turbine washing sewage tank, and 105 is the gas turbine washing sewage filter. In this embodiment, the unit runs for a period of time, and the channel of the compressor is fouled, which makes the performance of the unit decline. The gas turbine is washed with water to clean the fouling, so that the performance of the compressor is basically restored to the best operating condition. There are two ways to wash the compressor: offline water washing and online water washing. In this embodiment, online water washing is implemented.

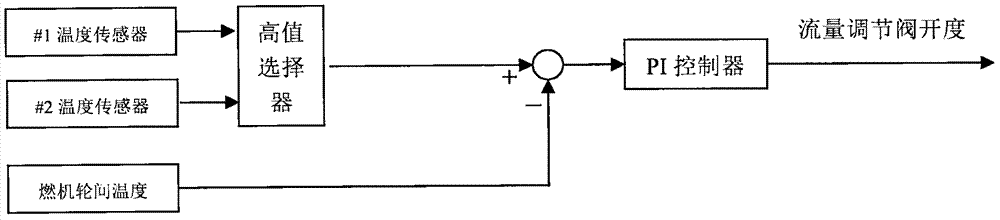

[0021] The compressor water washing system mainly consists of water washing tank, cleaning pump, heat exchanger, water washing nozzle, water supply pressure regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com