Power-shift transmission for a commercial vehicle

A technology for power shifting, commercial vehicles, applied in the direction of vehicle gearbox, vehicle components, transmission, etc., can solve the problem of not discussing multi-level upshift transmission drive torque and other issues, achieve extended maintenance intervals, save space, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

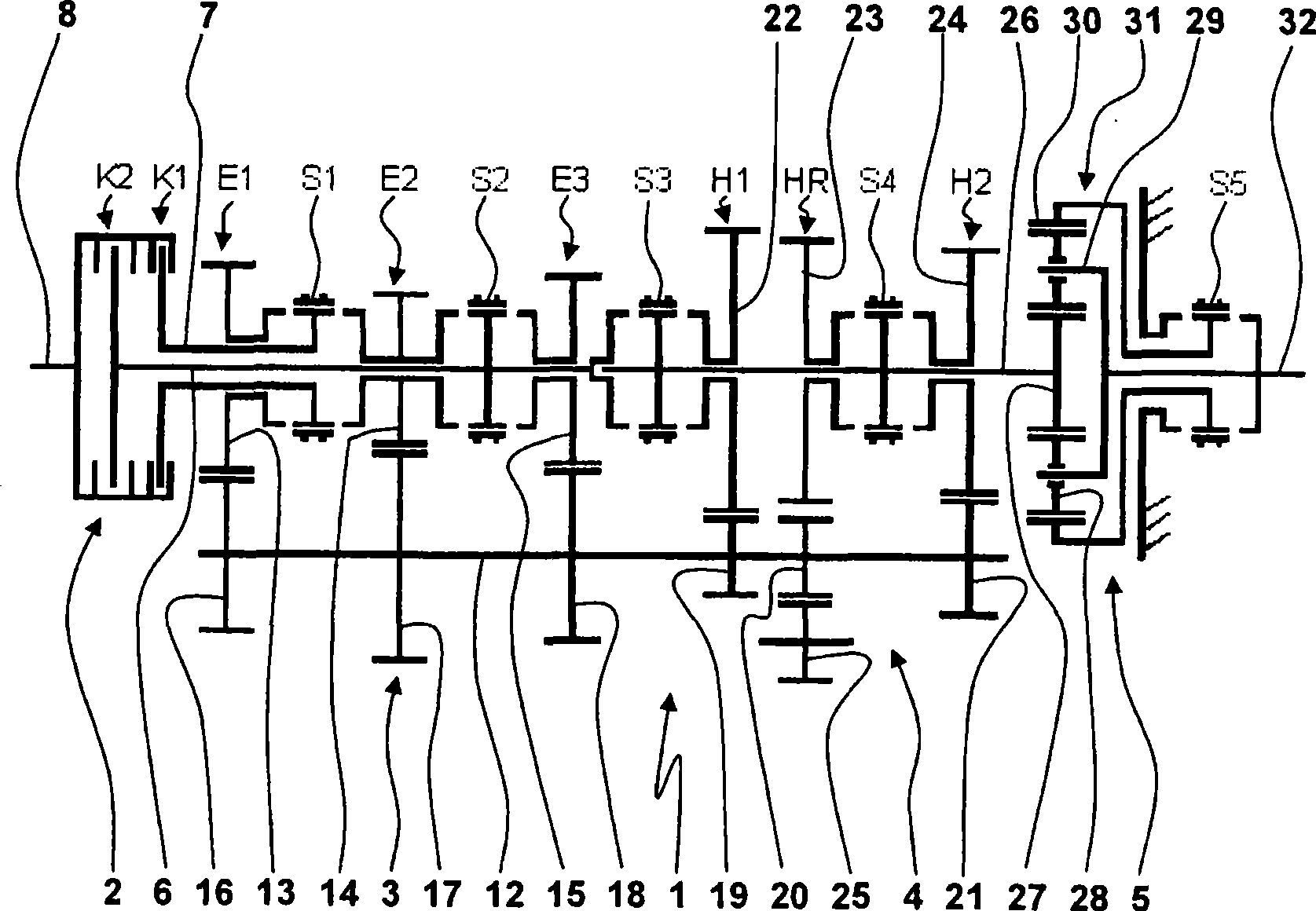

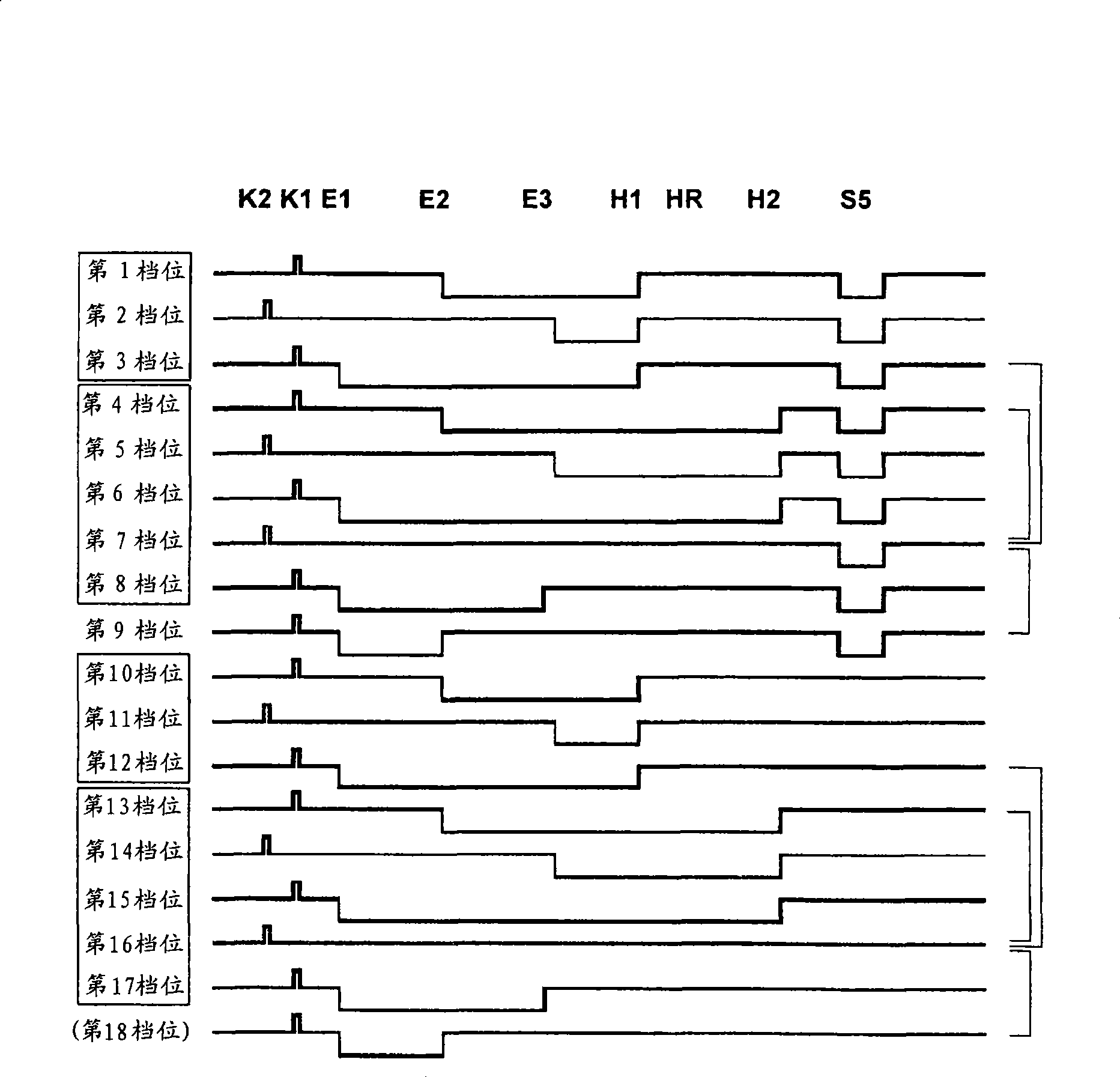

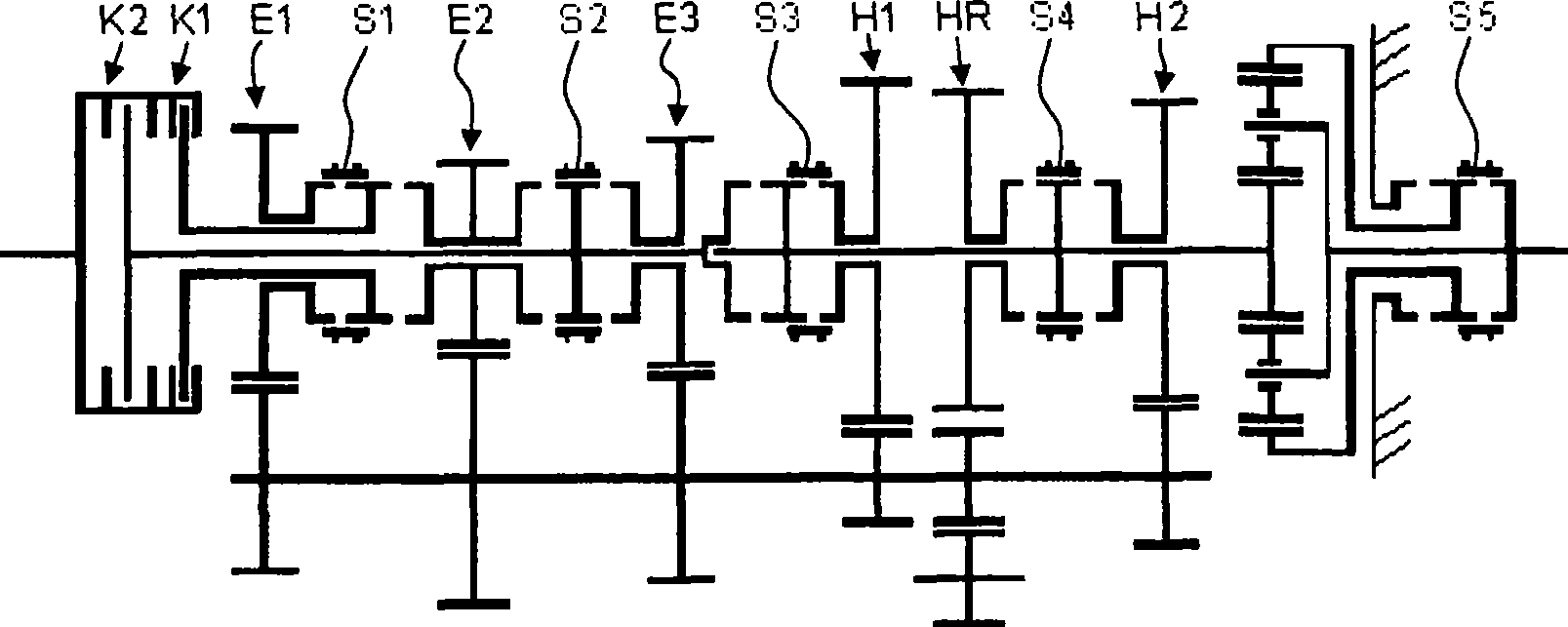

[0038] figure 1 A power shift transmission 1 is shown having a dual clutch 2 with two clutches K1 and K2 , a splitter assembly 3 , a main assembly 4 and a rear assembly 5 .

[0039] The splitter assembly 3 comprises two input shafts 6, 7 which can be selectively enabled by means of clutches K1, K2 or by means of a crossover controller ( ) is drivingly connected with the transmission input shaft 8. In the splitter assembly 3 , the countershaft 12 can be driven in different transmission ratios via input constants E1 , E2 , E3 associated with the respective gear plane. The input constants E1 , E2 , E3 include drive input side gears 13 - 15 that are meshed with the drive output side gears 6 - 18 of the input constants E1 , E2 , E3 . The gears 13 - 15 are designed as freewheels, wherein the gear 13 is mounted rotatably relative to the input shaft 7 and the gears 14 , 15 are mounted rotatably relative to the input shaft 6 . The input shaft 7 is designed as a hollow shaft and sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com