Test machine and test method for real-time and dynamic observation of end surface torsion friction and abrasion of friction interface

A friction interface and torsional friction technology, applied in measurement devices, mechanical devices, instruments, etc., can solve problems such as the inability to dynamically observe the micro-wear state in real time, the inability to observe the real-time movement of wear debris, and the destruction of the continuity of the friction process. Improves performance and life, facilitates machining and handling, and reduces torsional wear and tear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

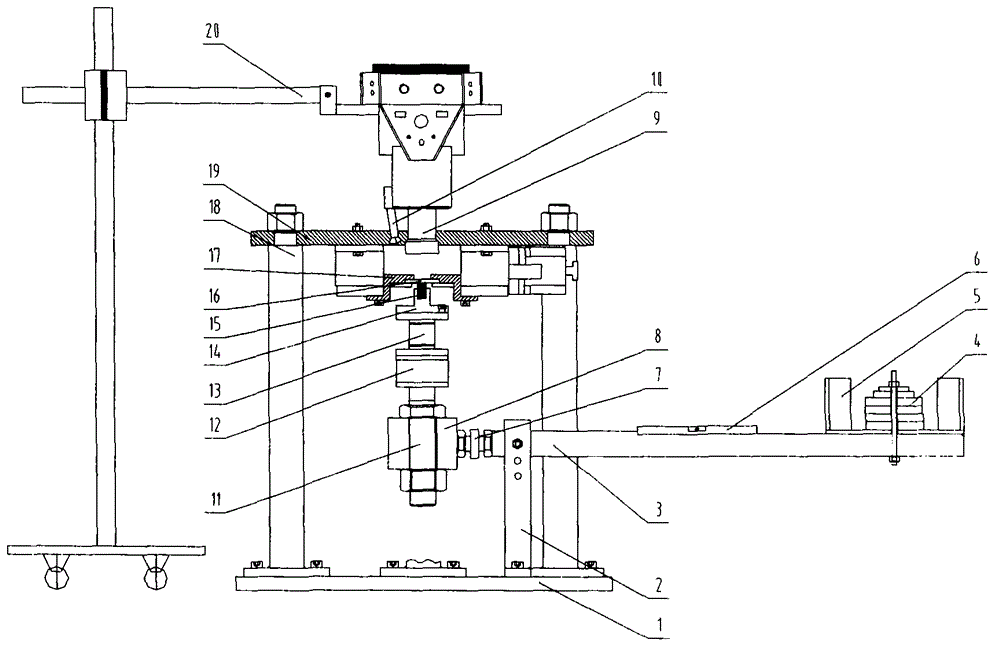

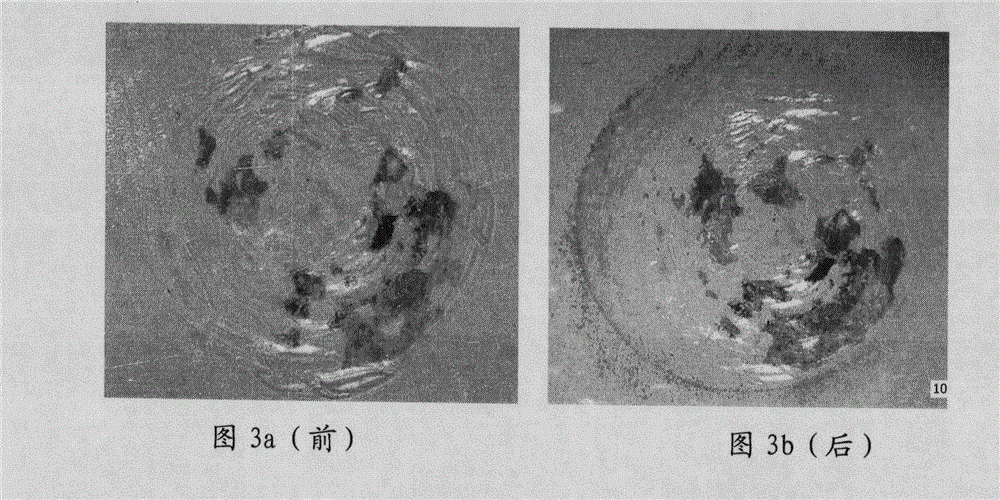

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the following in conjunction with the attached Figures 1 to 5 And embodiment, the present invention is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

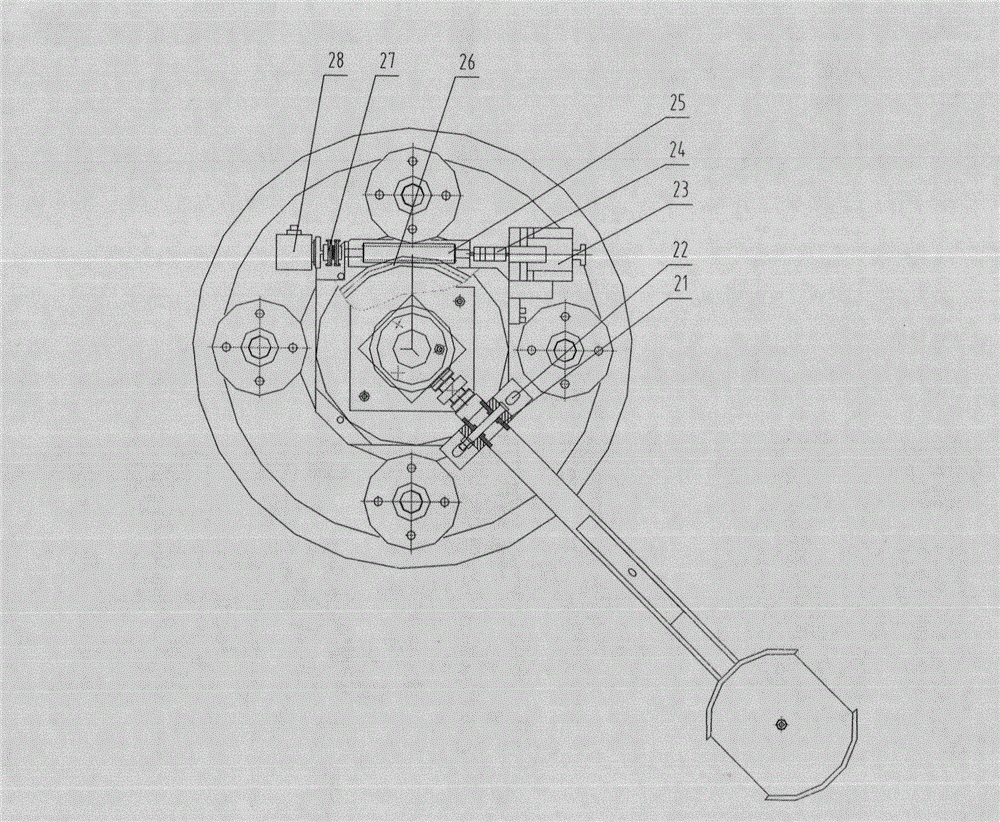

[0027] The end face torsion friction and wear testing machine for real-time dynamic observation of the friction interface of the present invention is mainly composed of a pressure loading device, a rotary platform, a friction interface observation device, and an adjustment device. The pressure loading device includes a lever bracket 2 arranged on the base 1, a lever 3 with the lever bracket as a fulcrum, a threaded hole expansion groove 22 at the lower end of the lever bracket 2, a weight 4 and a screw thread on one side of the lever fulcrum. The weight plate 5 for fixing the weight, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com