Disc brake with floating caliper

A technology of disc brake and floating caliper, which is applied in the direction of brake type, axial brake, brake parts, etc., and can solve the problems of high brake and brake pipeline manufacturing requirements, large friction plate consumption, and small friction plate area. and other problems, to achieve the effect of increasing the stability of the connection installation, increasing the installation area, and improving the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

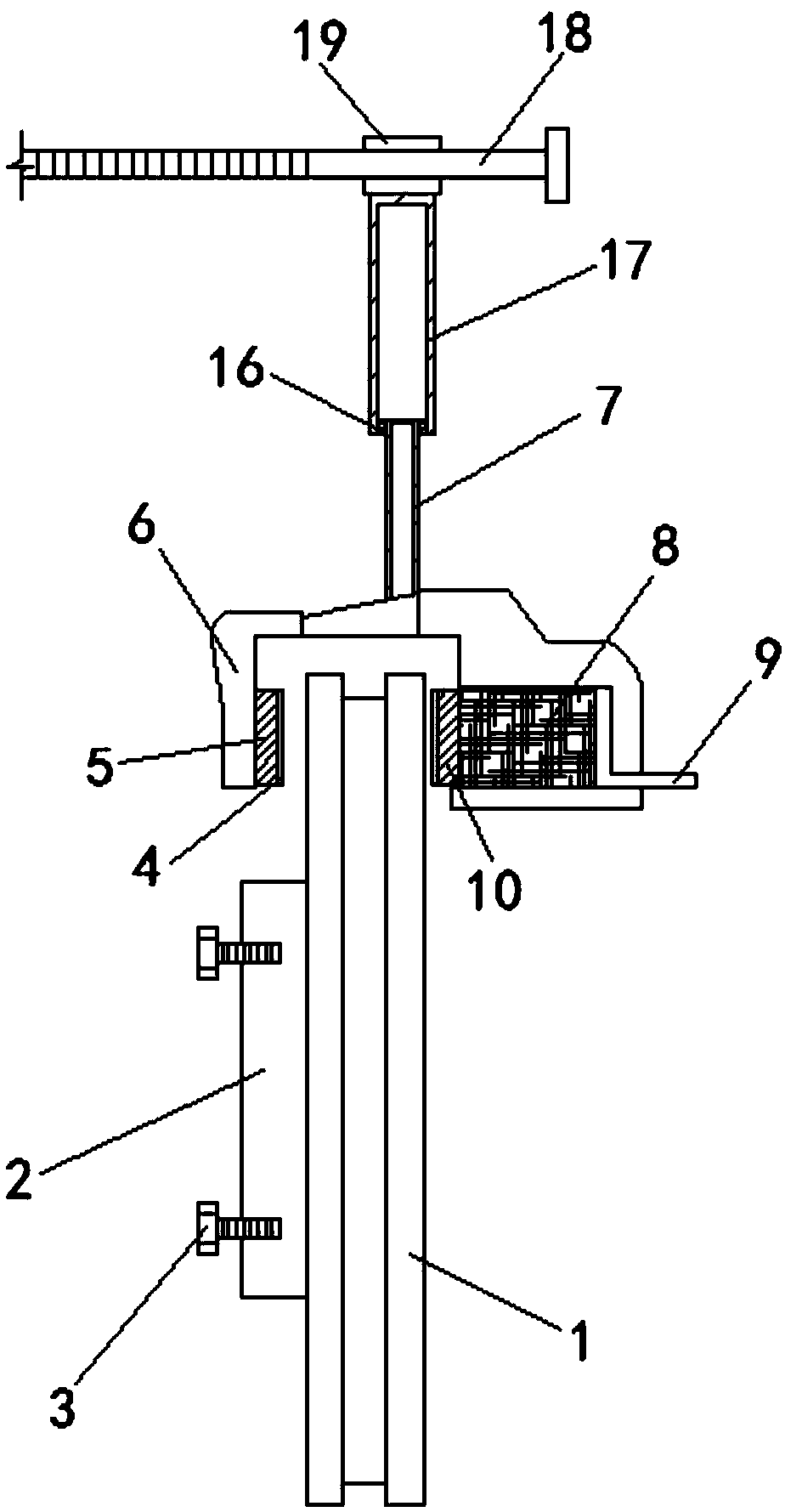

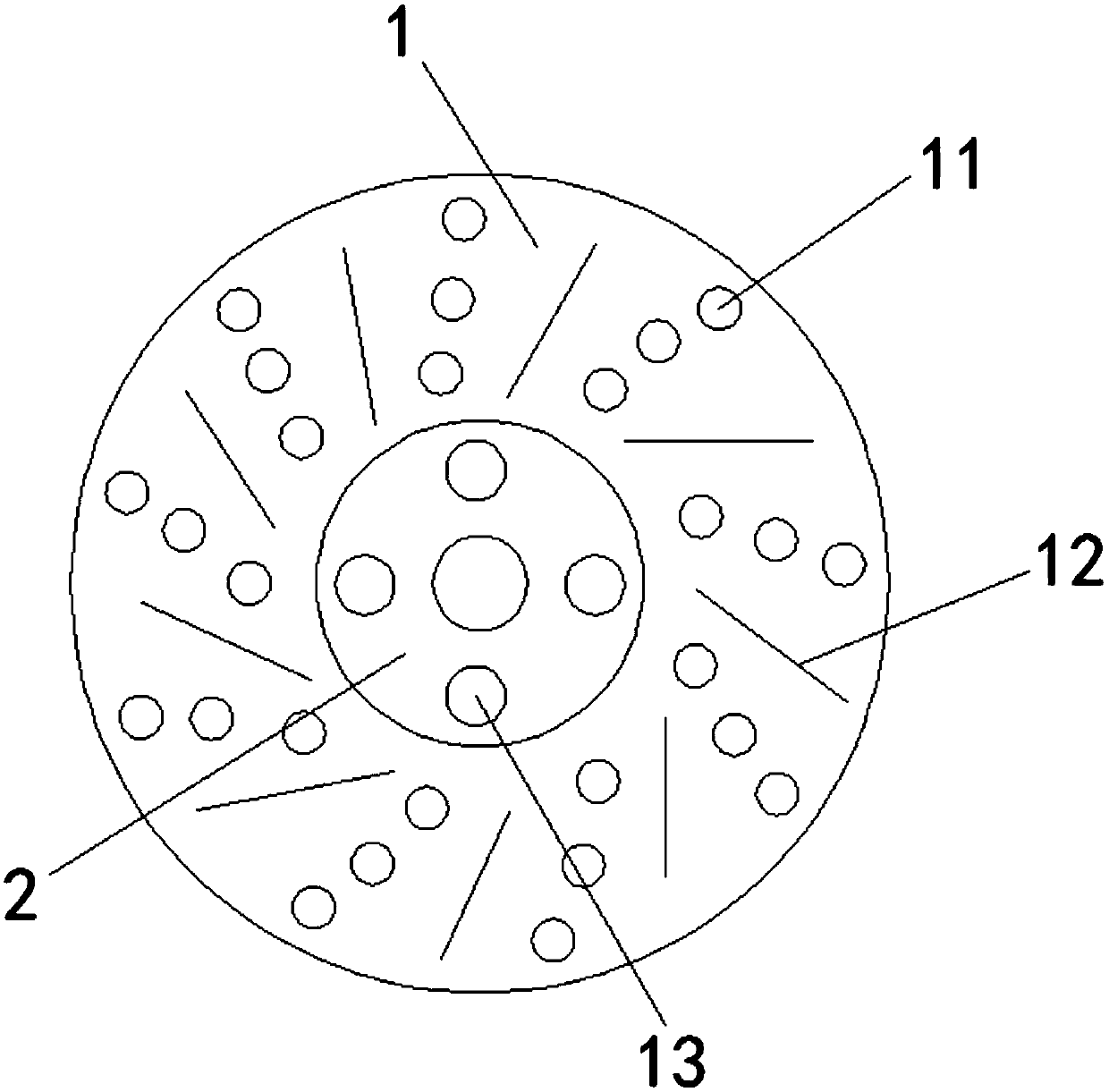

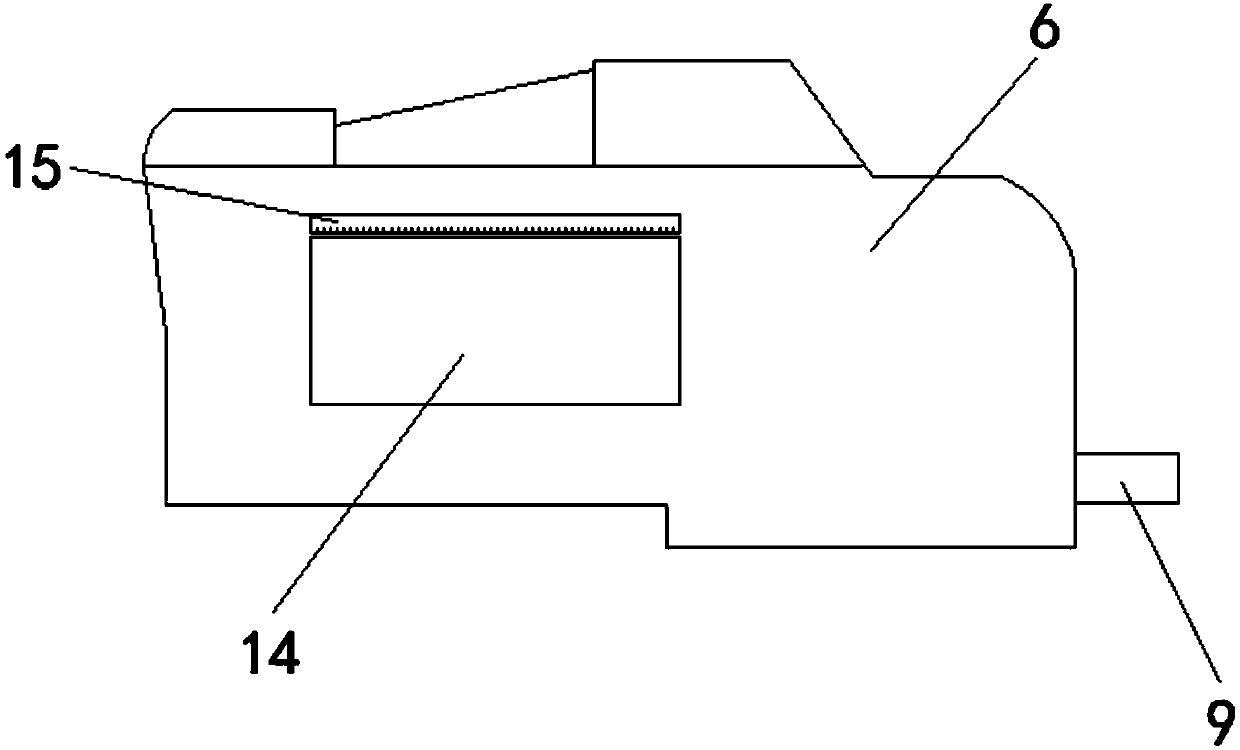

[0021] Combine below Figure 1-3 The floating caliper disc brake of the present invention is described in detail: a floating caliper disc brake includes a brake disc 1, a hub 2, a brake caliper 6, a piston 8 and an oil pipe 9, and the left side of the brake disc 1 is in the middle A wheel hub 2 is arranged on the position, and the wheel hub 2 is fixedly connected with the brake disc 1. A plurality of bolt holes 13 are arranged on the wheel hub 2, and bolts 3 are arranged in the bolt holes 13. The two sides of the brake disc 1 There are a number of scratches 12 arranged obliquely, and a number of through holes 11 are arranged between the scratches 12. The through holes 11 run through the brake disc 1, and a brake caliper 6 is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com