Effect device for forming stage-lighting effects

A stage lighting and effect wheel technology, which is applied in the field of stage lighting, can solve the problems of pattern wheel shaking, slow movement, and increased manufacturing costs, and achieve the effects of increased change speed, sufficient range of motion, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

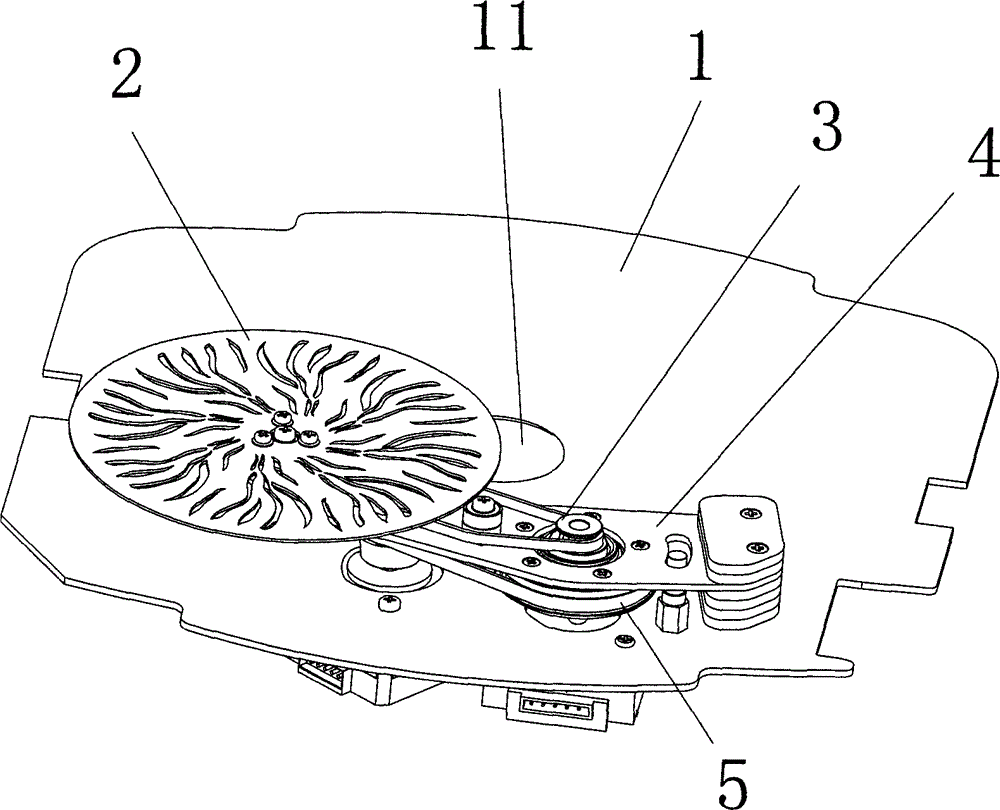

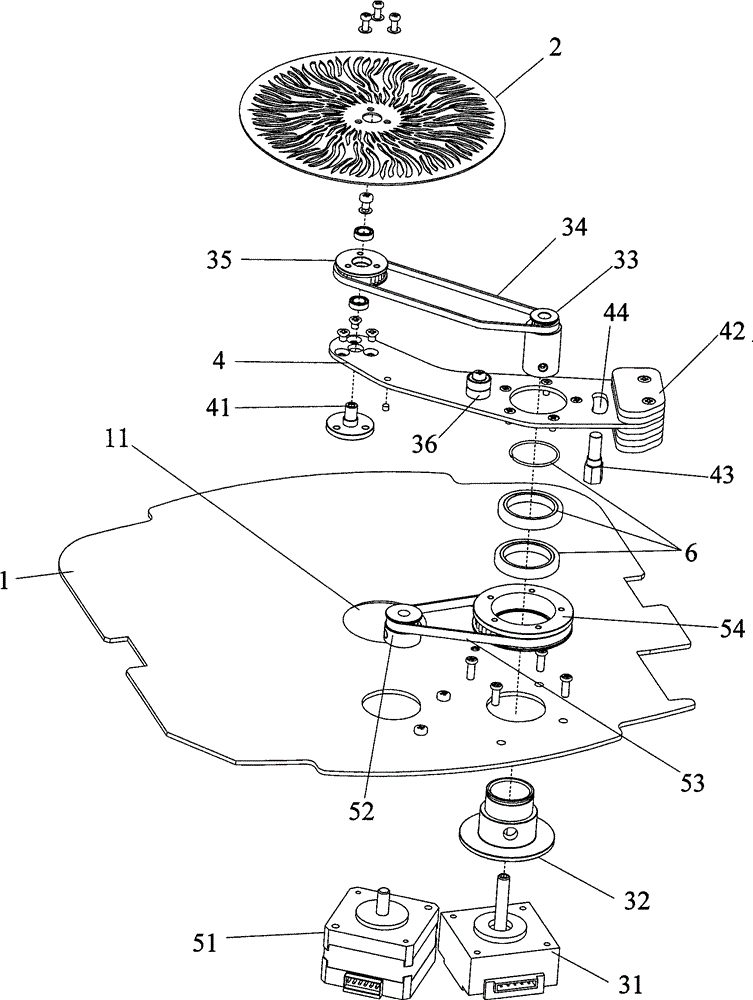

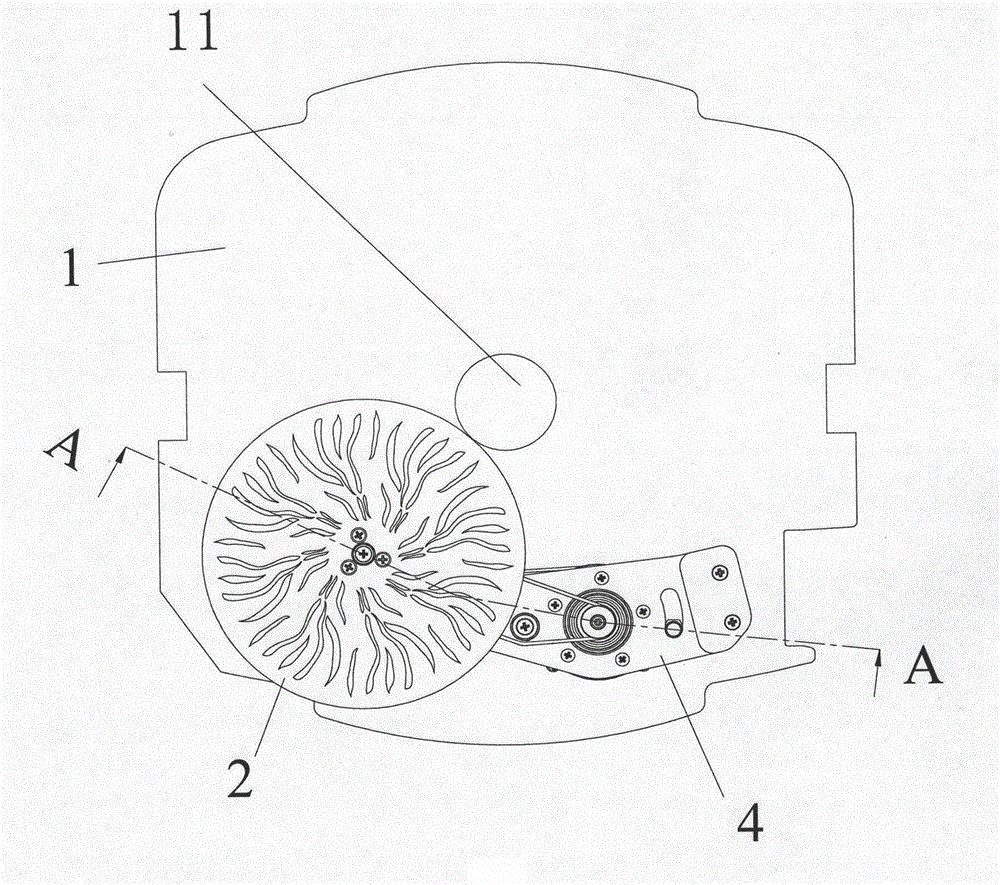

[0039] refer to figure 1 , the effect device used to shape the stage lighting effect includes:

[0040] A total support 1, the total support 1 is provided with a light-transmitting hole 11 for the passage of light beams;

[0041] The effect wheel 2, the effect wheel 2 can be a pattern wheel with irregular pattern holes, it can also be a color filter, a frosted glass sheet, a prism or any optical effect element, or a combination of the above elements;

[0042] Rotating mechanism 3, used to make the effect wheel 2 rotate around the axis of the effect wheel 2;

[0043] The moving mechanism is used to move the effect wheel 2 relative to the light transmission hole 11, so that the effect wheel 2 overlaps with the light transmission hole 11 or does not overlap with the light transmission hole 11, thereby producing different lighting effects.

[0044] refer to figure 1 Or 2, moving mechanism comprises rocking arm 4 and moving driving mechanism 5, and moving driving mechanism 5 com...

Embodiment 2

[0054] The effect devices used to shape the stage lighting effects include:

[0055] A total support 1, the total support 1 is provided with a light-transmitting hole 11 for the passage of light beams;

[0056] The effect wheel 2, the effect wheel 2 can be a pattern wheel with irregular pattern holes, it can also be a color filter, a frosted glass sheet, a prism or any optical effect element, or a combination of the above elements;

[0057] Rotating mechanism 3, used to make the effect wheel 2 rotate around the axis of the effect wheel 2;

[0058] The moving mechanism is used to move the effect wheel 2 to a position overlapping with the light-transmitting hole 11 or a position not overlapping with the light-transmitting hole 11 , so as to produce different lighting effects.

[0059] The moving mechanism includes a rocking arm 4 and a moving driving mechanism 5 , the moving driving mechanism 5 is a moving driving motor, and the output shaft of the driving motor is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com