Ultrasonic lace machine

An ultrasonic and lace machine technology, applied in textile and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of inconvenient layout, large space occupied, long transmission path, etc., and achieve convenient layout, short path and installation space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

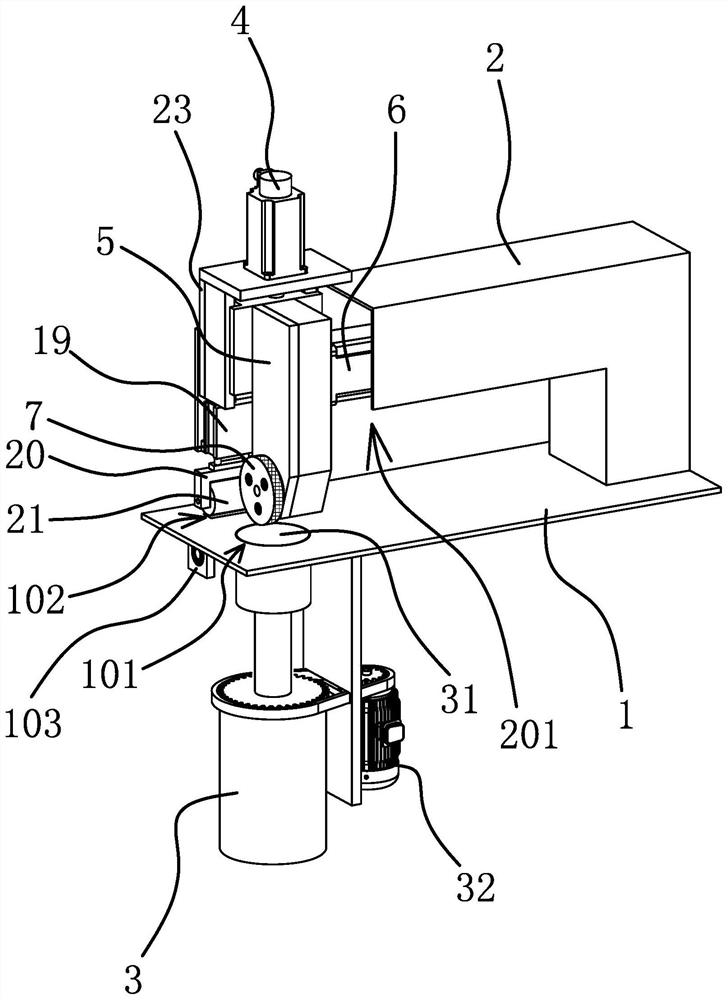

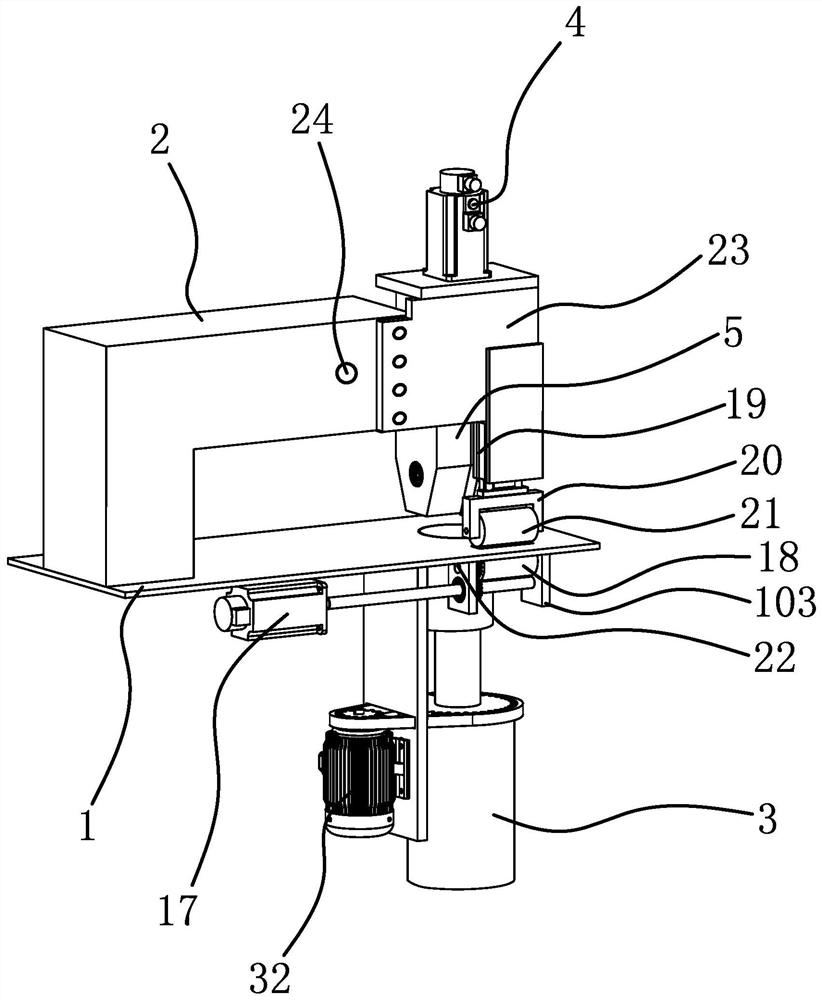

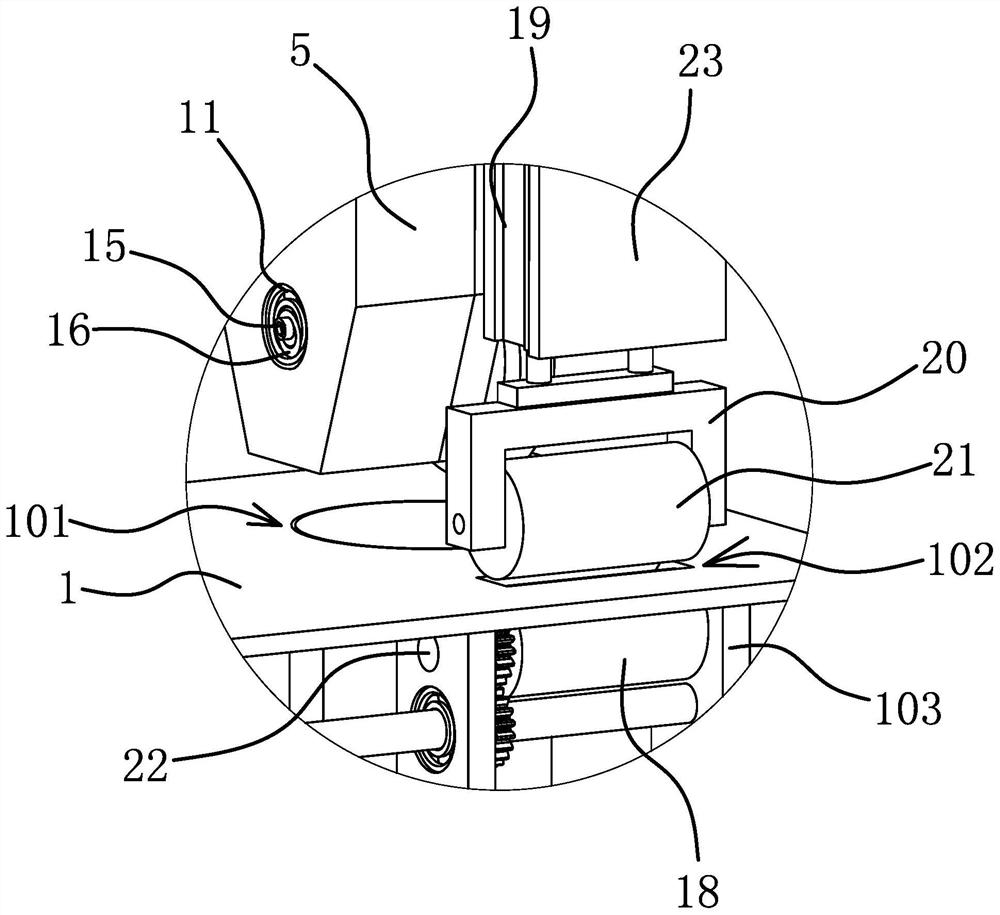

[0033] like figure 1 , figure 2 As shown, the ultrasonic lace machine includes a worktable 1, a machine head 2, an ultrasonic transducer assembly 3, a fifth driving member 32, a first driving member 4, a sliding frame 5, a second driving member 6, a flower wheel 7, a transmission mechanism, The third driving member 17 , the fourth driving member 19 and the mounting plate 23 . In this embodiment, the first driving member 4 and the fourth driving member 19 are driving cylinders, and the second driving member 6, the third driving member 17 and the fifth driving member 32 are servo motors. In actual production, the first driving member 4 and the fourth driving member 19 are driving oil cylinders, and the second driving member 6, the third driving member 17 and the fifth driving member 32 can be rotary cylinders.

[0034] The handpiece 2 is fixed above the workbench 1, the interior of the handpiece 2 has a cavity, the ultrasonic transducer assembly 3 is fixed under the workbench...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as those of the first embodiment. The difference is that in this embodiment, the handpiece 2 has a downwardly protruding accommodating cavity, and along the vertical direction, the accommodating cavity is located in the second driving member Right below 6, the second driving member 6 can move down to be located in the accommodating cavity.

Embodiment 3

[0044] The structure and principle of this embodiment are basically the same as those of the first embodiment. The difference is that in this embodiment, the transmission mechanism can be a gear set, and through the cooperation of multiple gears, the second driving member 6 can drive the flower wheel 7 to rotate. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com