Aluminum cast rolling efficient cooling device and cooling process

A cooling device, casting and rolling technology, applied in the field of aluminum casting and rolling production, to achieve the effect of improving cooling rate, uniform distribution, and accelerating metal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

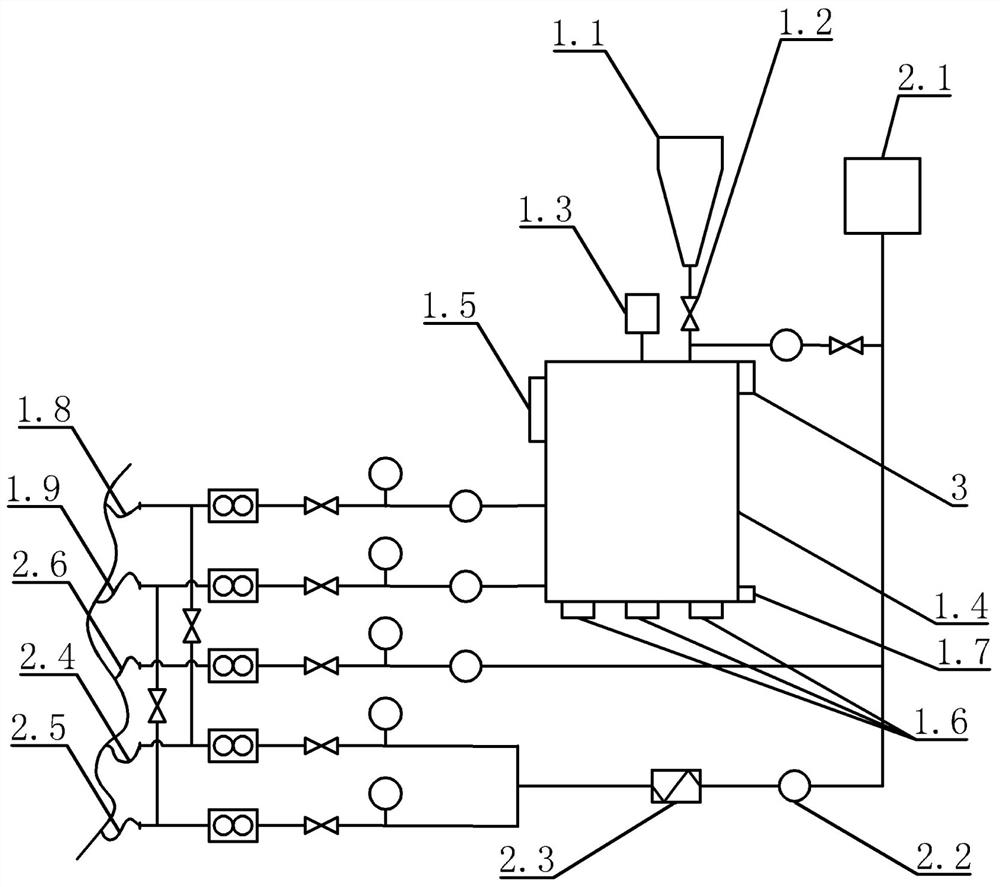

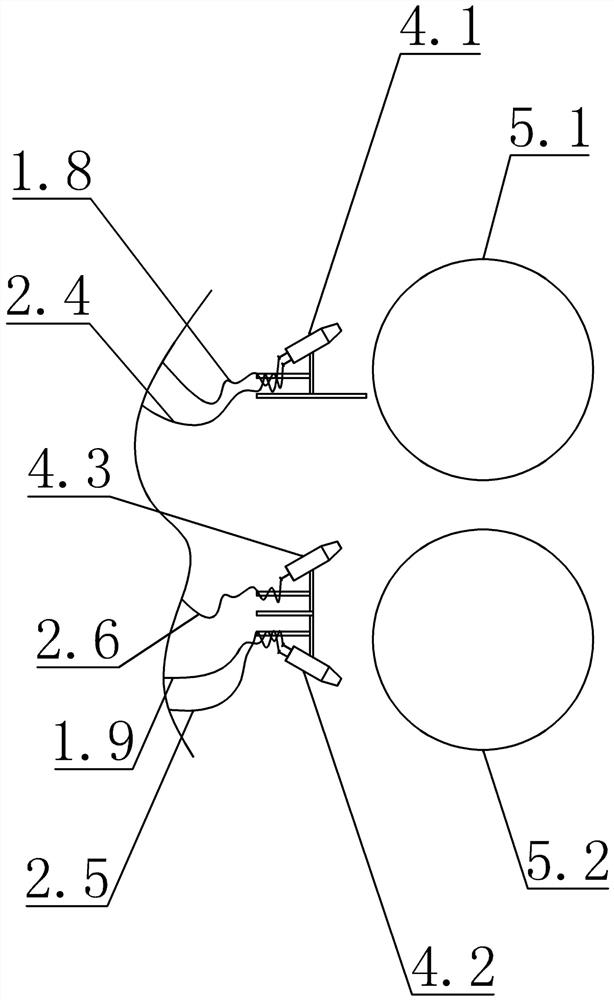

[0040] Such as figure 1 , figure 2 As shown, a high-efficiency cooling device for aluminum casting and rolling is used in the casting and rolling process of cast rolling plates, wherein, the upper casting roll 5.1 and the lower casting rolling roll 5.2 are used to cast and roll cast rolling plates in the casting rolling process, including graphite and liquid nitrogen. Mixing device, spraying device, control device with manual and automatic control modes 3.

[0041] The spraying device includes: an upper nozzle 4.1 capable of adjusting the pitch angle, an upper nozzle base capable of moving axially parallel to the upper casting roll 5.1, a lower nozzle 4.2 capable of adjusting the pitch angle, and a lower nozzle capable of axially moving parallel to the lower casting roll 5.2. Nozzle base; the upper nozzle 4.1 is located above the cast rolling plate, set on the upper nozzle base, and aligned with the upper casting roll 5.1, and the lower nozzle 4.2 is located under the cast r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com