Plastic plate periphery polishing machine

A technology of polishing machine and plastic plate, applied in the field of polishing machine, can solve the problems of increased cost, inability to chamfer the corners of the plastic plate, inability to slot the plastic plate, etc., and achieve the effects of cost reduction, convenient and accurate position adjustment, and reduction of processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

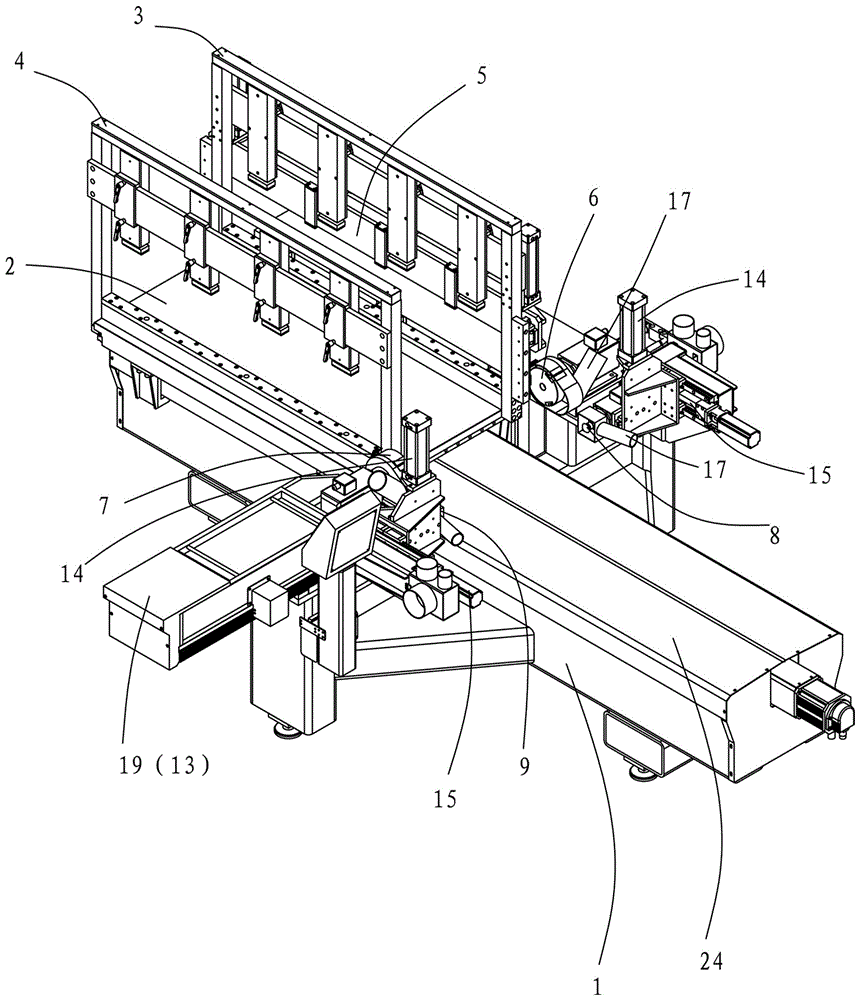

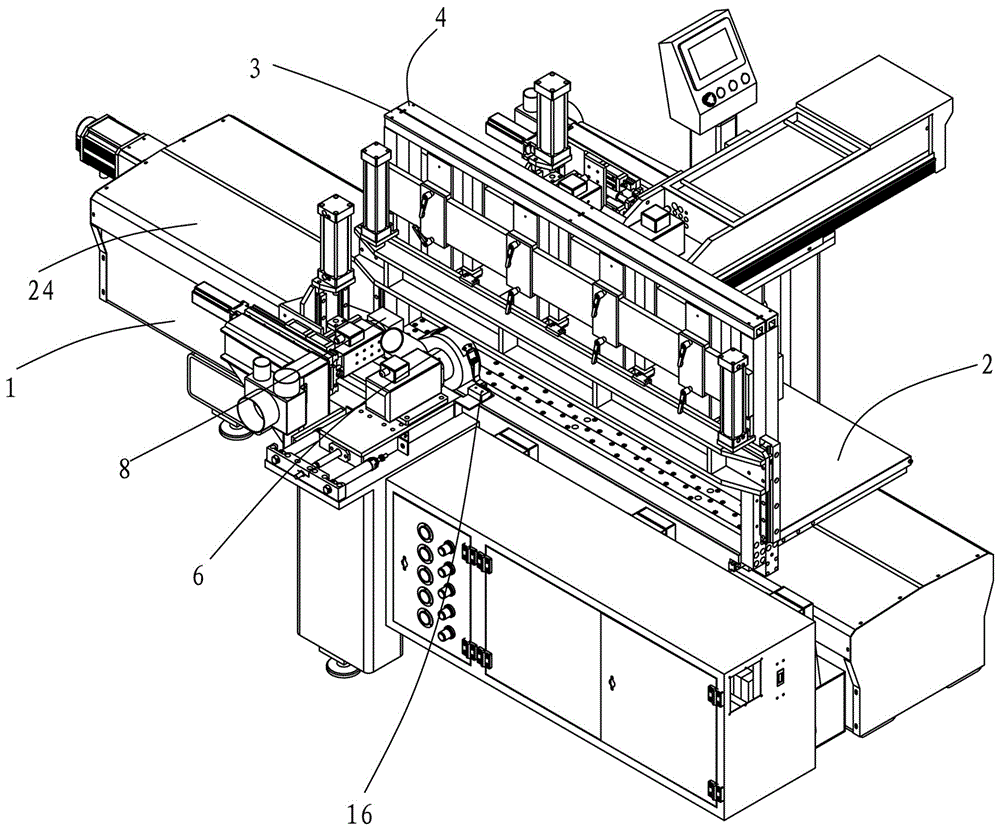

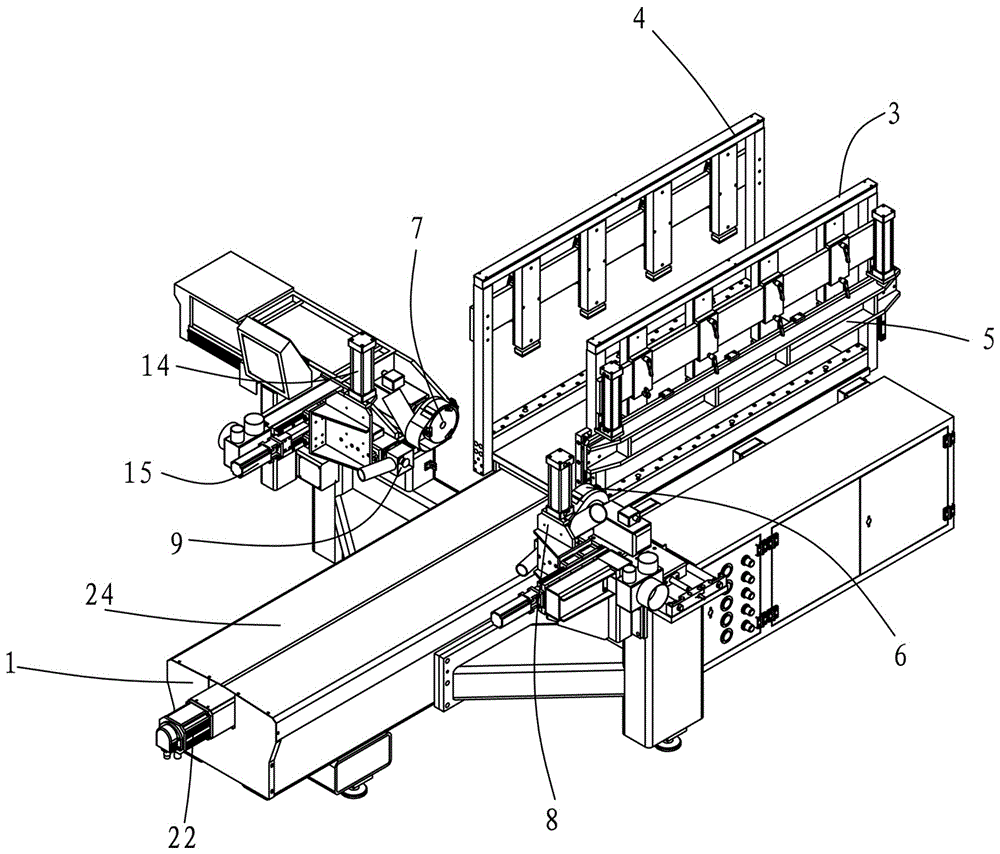

[0025] Embodiment 1, combining Figure 1 to Figure 7 , a peripheral polishing machine for plastic plates, comprising a machine tool 1, a slide table 2, a pressing device, a polishing device and a chamfering device.

[0026] The pressing device is arranged on the sliding table 2, and the pressing device includes a set of positioning pressing row 3 fixed on the sliding table and a set of dynamic pressing row 4 that can move relative to the positioning pressing row 3, and the dynamic pressing row 4 Can be close to or away from the positioning binder row 3 by manual or electric adjustment, the positioning binder row 3 is provided with a positioning plate 5, and the positioning plate 5 can move up and down relative to the surface of the slide table 2 through the cylinder drive. The main function of the positioning plate 5 is to locate the initial position of the plastic plate, and calculate the distance between the positioning binder row and the dynamic binder row according to the ...

Embodiment 2

[0032] Example 2, combined with Figure 8 and Figure 9 , Embodiment 2 is mainly to carry out slotting to the periphery of plastic plate, therefore only need to pull down the cutter of the chamfering device of Embodiment 1, replace the cutter 32 of slotting device and get final product, cutter 32 is driven to rotate by motor 33, at this moment Two sets of chamfering devices become two sets of slotting devices 30,31. The structure and working principle of embodiment 2 are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com