Supersonic wind tunnel velocity field calibration and measurement total pressure tube vibration suppression device

A total pressure exhaust pipe and vibration suppression technology, which is applied in the field of wind tunnels, can solve the problems of severe total pressure exhaust pipe vibration, deformation of connecting rods, and impact on test accuracy, and achieve the effects of suppressing vibration, enhancing stiffness, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

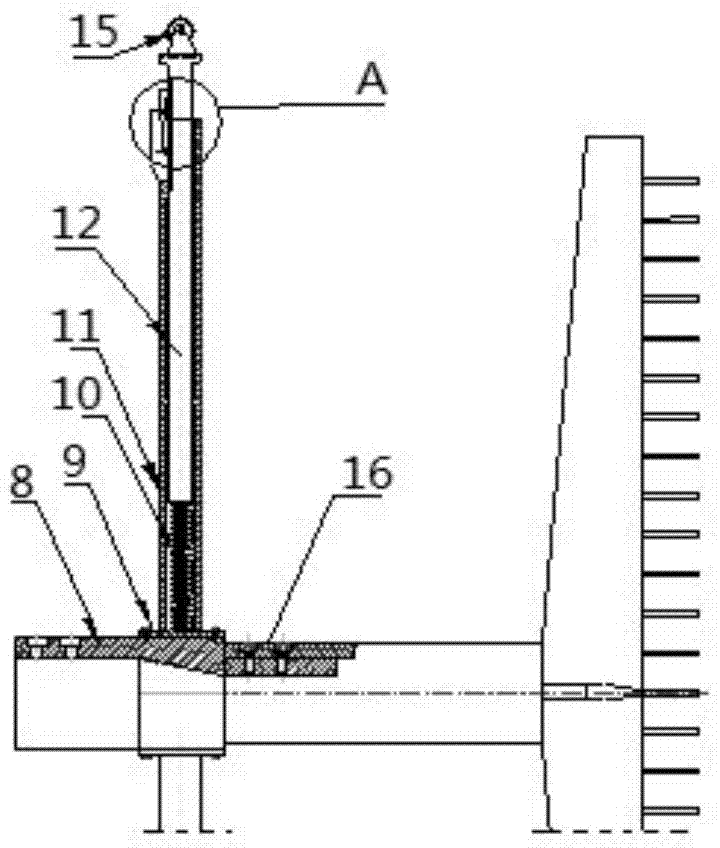

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

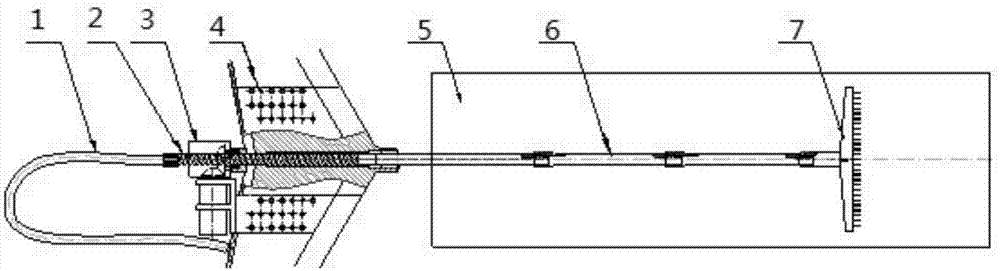

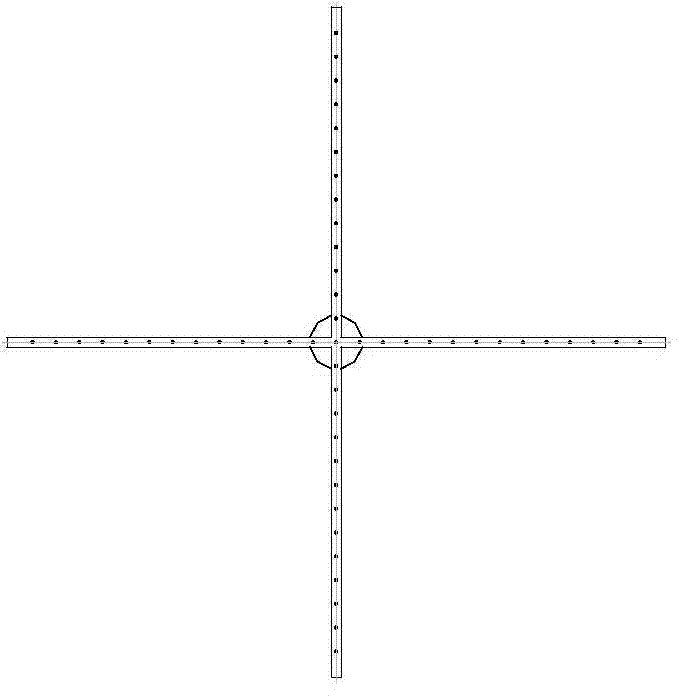

[0028] see image 3 , Figure 4 and Figure 5 , the present invention provides a vibration suppression device for calibrating the velocity field of a supersonic wind tunnel to measure the total pressure exhaust pipe, comprising: a connecting seat 9, which has an axis, and the connecting seat has two connections distributed on the axis Ends 8, 16; a support mechanism, which includes a support sleeve 11, a support rod 12 and a first elastic member 10, wherein one end of the support sleeve is connected to the connecting seat, and the other end has an opening, and the support rod Sleeved in the support sleeve, and the free end of the support rod protrudes from the opening, the first elastic member is arranged inside the support sleeve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com