Automatic welding machine for stainless steel circumferential weld

An automatic welding machine and stainless steel ring technology, applied in welding accessories, welding equipment, welding protection devices, etc., can solve the problems of inconvenient clamping and positioning, manual adjustment, and poor ductility of stainless steel pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

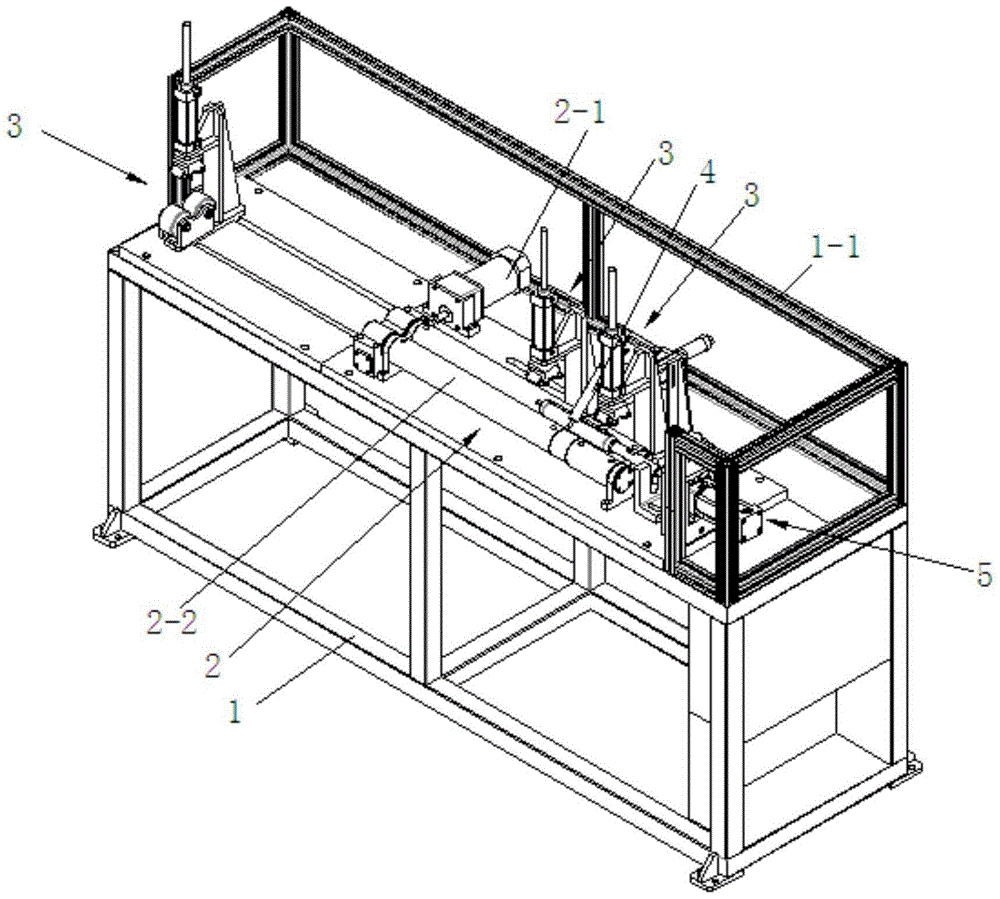

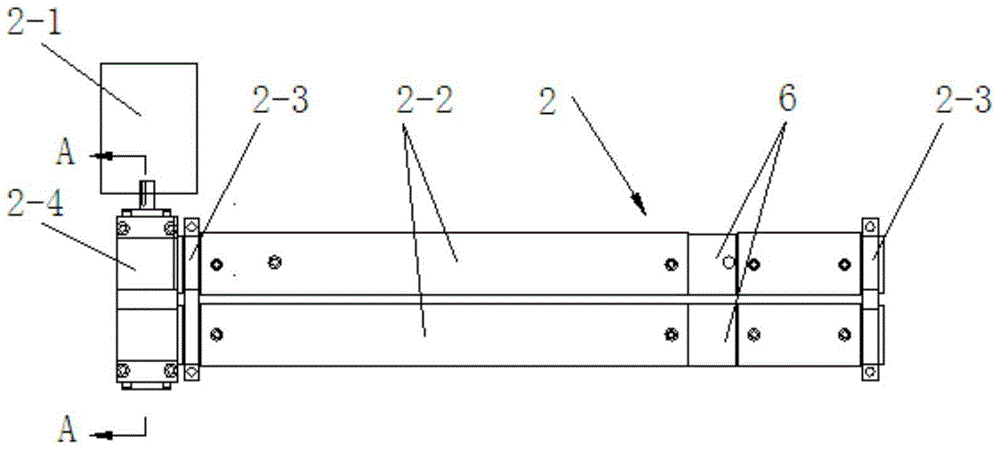

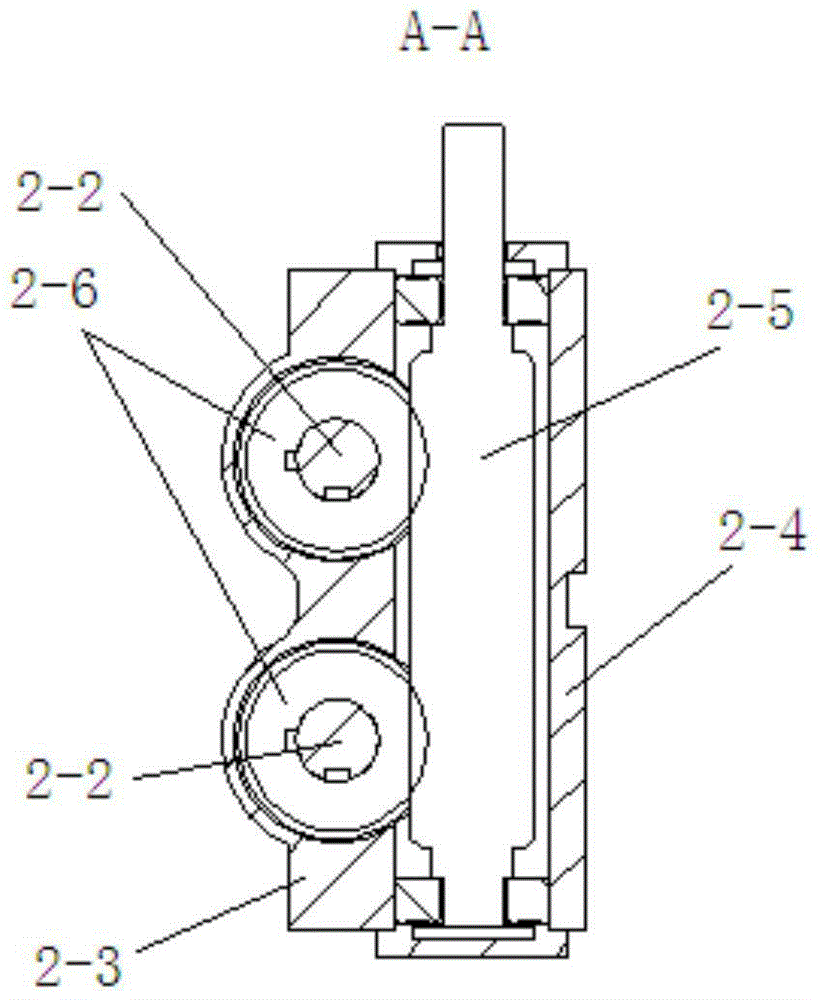

[0016] see figure 1 , 2 , 3, 4, and 5, a stainless steel girth weld automatic welding machine includes a frame 1, a pipe fitting rotating device 2, a pressing device 3 and a welding torch 4, and the welding torch 4 is fixedly connected to the frame 1, and the pipe fitting rotates Device 2 comprises motor 2-1, two rotating shafts 2-2, axle seat 2-3, worm screw seat 2-4, worm screw 2-5 and worm wheel 2-6, and described axle seat 2-3 is fixed with frame 1 connection, the two ends of the two rotating shafts 2-2 are rotationally connected with the respective shaft seats 2-3, and one end of the two rotating shafts 2-2 is equipped with a worm wheel 2-6, and the worm seat 2-4 is connected with the frame 1 fixed connection, the worm 2-5 is in rotation with the worm seat 2-4, and is connected with the motor 2-1, and the worm 2-5 is meshed with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com