Automatic horizontal position welding device for circular arc groove welds of elbow made of steel plate

The technology of groove welding seam and elbow is applied in the field of automatic horizontal welding device, which can solve the problems of increasing the labor intensity of welders, unstable welding quality, and high labor intensity of workers, so as to ensure the correct position, welding quality and structure. Simple, good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

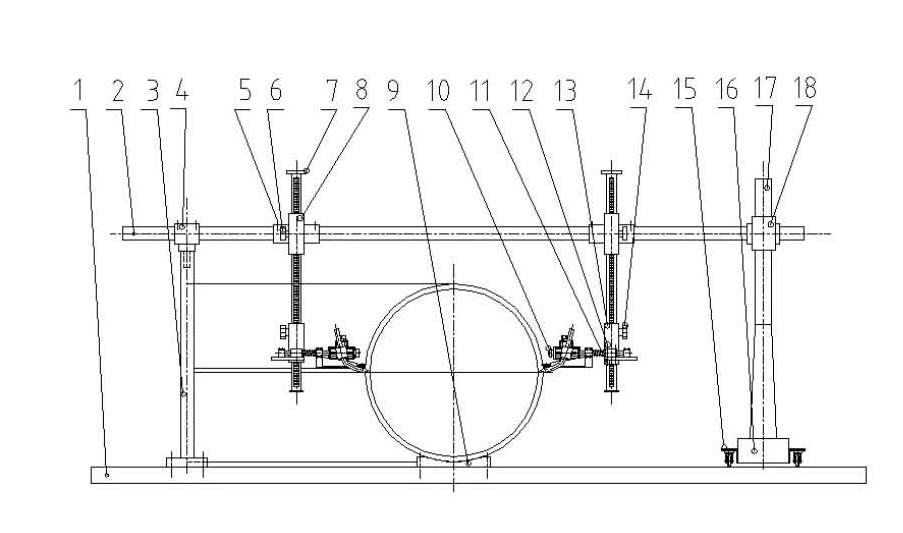

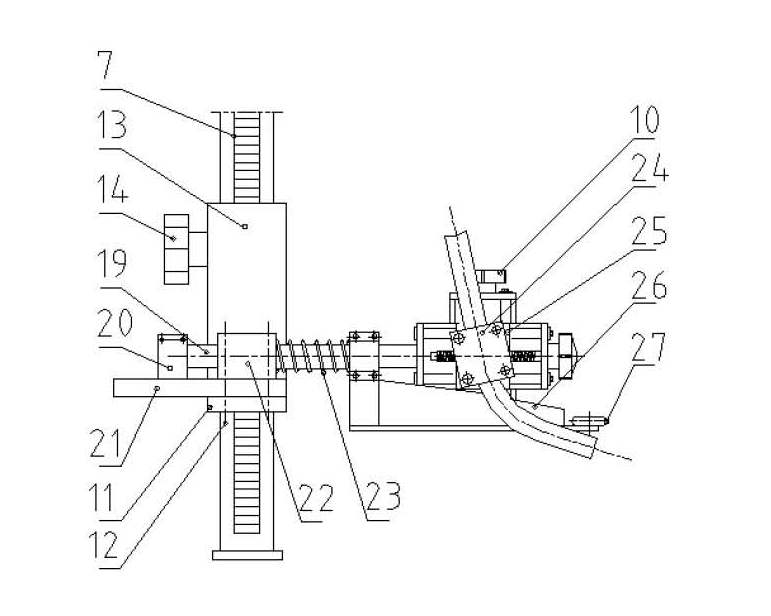

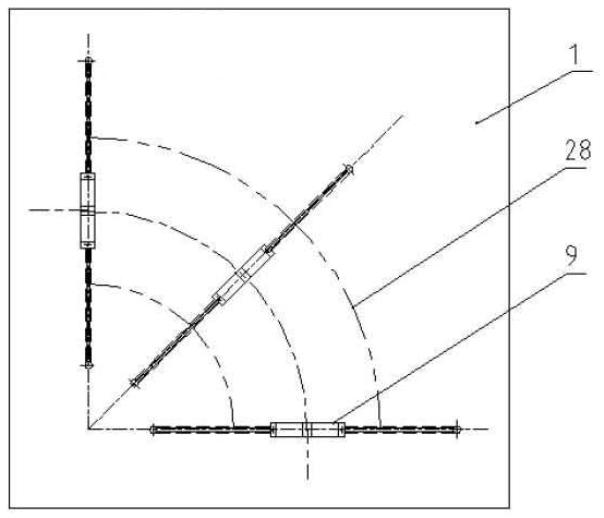

[0019] An automatic horizontal welding device for arc groove welds of steel plate elbows, including a working platform 1, a trolley positioning and rotating travel mechanism, and a welding torch positioning mechanism. The working platform 1 is a square steel plate, and the working platform 1 is provided with three trapezoidal grooves and three V-shaped horns 9 for elbow positioning, the three V-shaped horns 9 are evenly distributed within the 90-degree fan-shaped range of the working platform 1 and fixed in three trapezoidal grooves respectively; the trolley positioning rotary travel mechanism includes a center Axis 3, connecting rod rotating shaft 4, connecting rod 2, connecting rod column connecting piece 18, trolley column 17 and walking trolley 16, central axis 3 is fixed to working platform 1, and connecting rod 2 rotates and cooperates with central axis 3 through connecting rod rotating shaft 4 , the trolley column 17 is fixed with the connecting rod 2 through the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com