Adhesion type spherical face point closing block

A bonding type and block technology, which is applied in the direction of connecting components, threaded fasteners, nuts, etc., can solve the problems of low machining accuracy, broken metal streamlines, poor consistency, etc., and achieve high accuracy, simple structure, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation, structure, features and functions of the adhesive spherical point closing block proposed according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

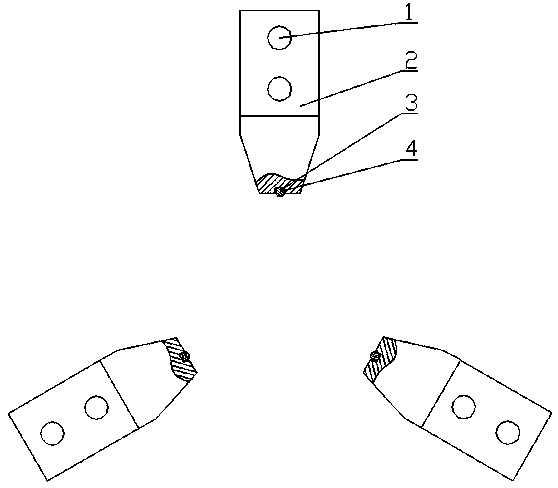

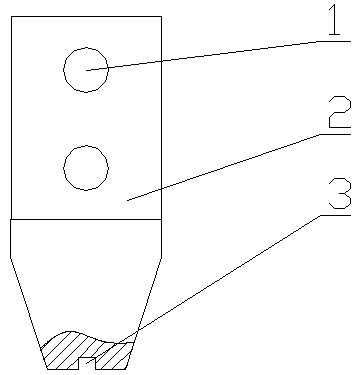

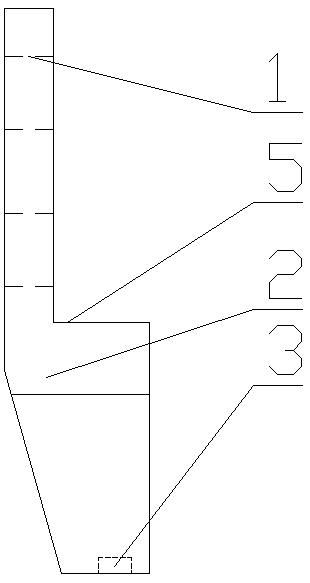

[0018] see Figure 1 to Figure 3 , the adhesive spherical point closing block of the present invention includes a closing block main body 2 and a closing block pressure head 4, wherein: a groove body 3 is arranged at the front end of the closing block main body 2, and a spherical closing block pressure head 4 is installed in the groove body 3, The three closing block main bodies 2 are arranged in a 120° circular array, and the closing block pressing heads 4 on the three closing block main bodies 2 form a closing cavity. A mounting hole 1 and a positioning step 5 are provided on the main body 2 of the closing block. The closing block main body 2 and the closing block pressure head 4 are bonded by organic glue. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com