Connecting pipe processing technology and clamping fixture

A processing technology and fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that the processing accuracy of the connecting pipe cannot meet the processing requirements, and the processing accuracy of the end face cannot be guaranteed, so as to facilitate clamping and positioning, ensure The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

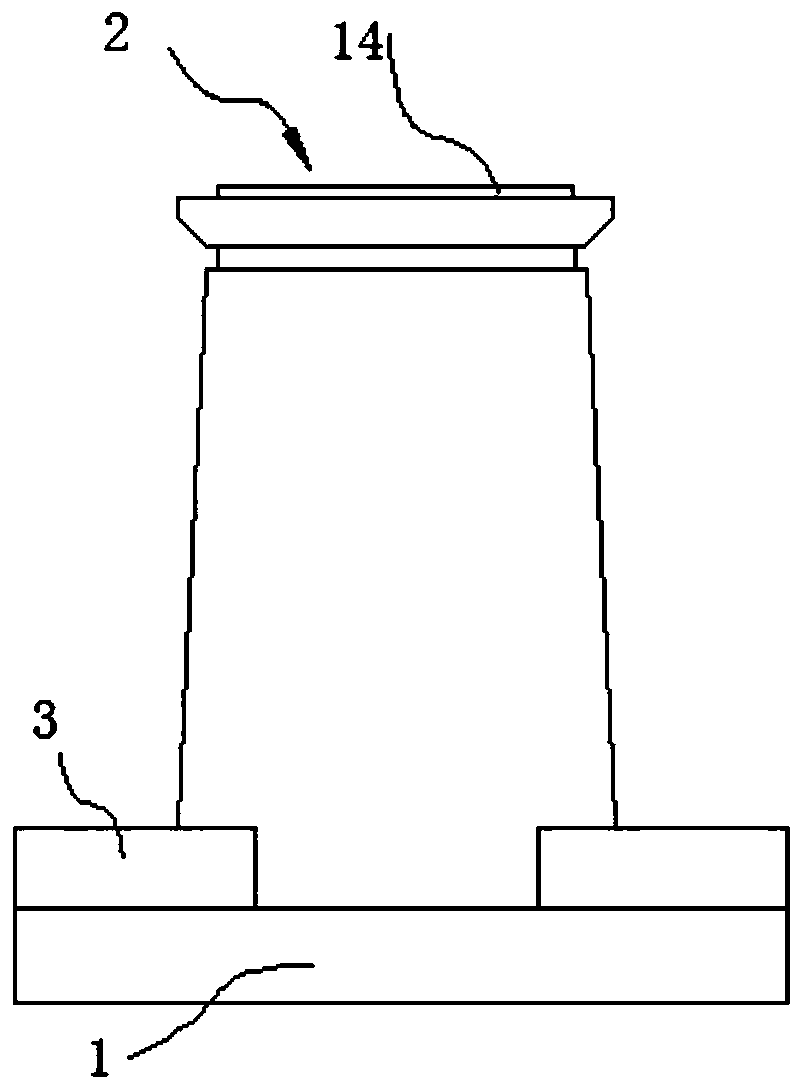

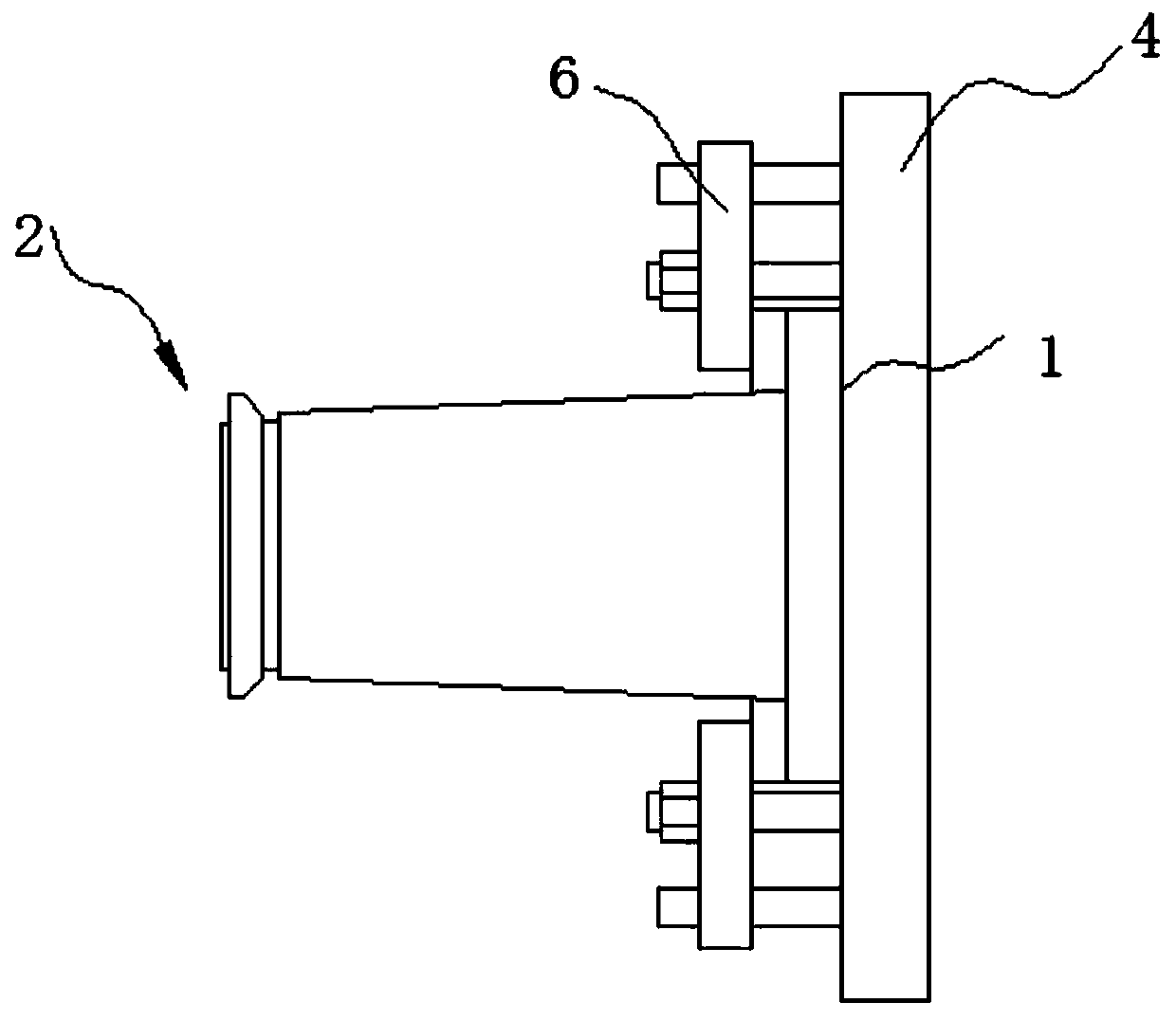

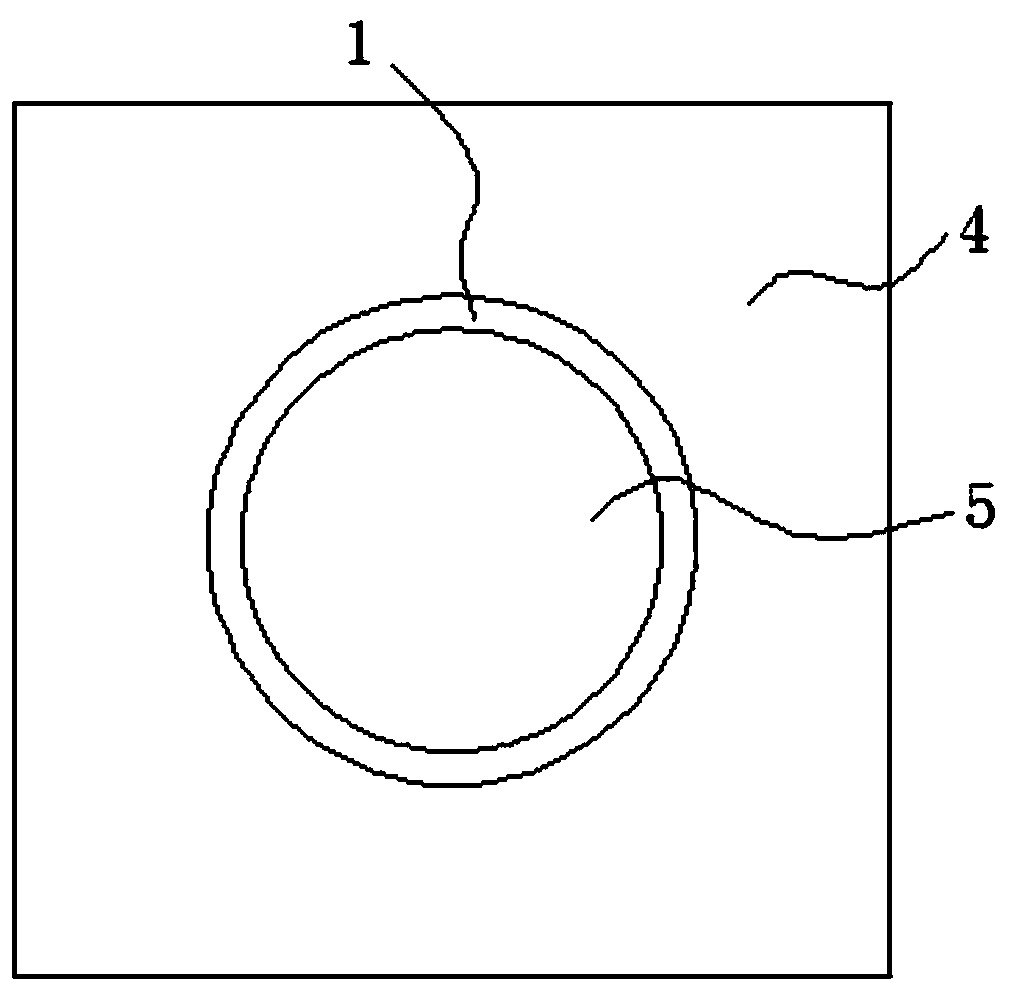

[0029] like figure 1 Shown, a kind of processing technology of taking over, comprises the following steps:

[0030] Step 1: rough and fine milling the end face of the big end 1 of the connecting pipe;

[0031] Step 2: chamfering the port of the car to take over the big end 1;

[0032] Step 3: turning the small end 2 of the connecting pipe;

[0033] Step 4: Process the hole on the end surface of the small end 2 of the connecting pipe;

[0034] Step 5: Process the boss 3 on the back of the big end of the connecting pipe.

[0035] In the first step, each screw hole of the large end of the connecting pipe is also processed.

[0036] In the step three, the outer diameter of the small end of the connecting pipe is processed by turning, the end face of the small end of the connecting pipe is processed by turning, and the boss 14 on the end face of the small end of the connecting pipe is processed by turning.

[0037] In the step five, the screw holes on the boss 3 on the back of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com