Step shaft cylindrical plane lathe cutting and radial hole drilling clamp

A technology of external turning and radial drilling, which is applied in the field of clamping devices, can solve the problems that affect the processing quality, precision, efficiency, can not guarantee the symmetry of the hole, and the quality of the milling surface is not good, so as to achieve a simple structure , good elasticity, easy and safe production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

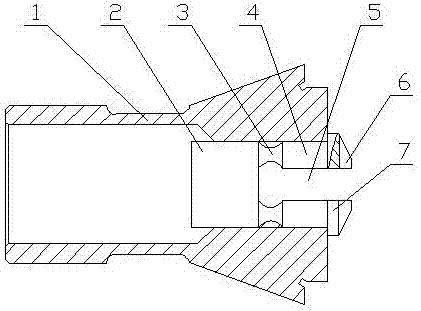

[0024] In the following, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of the jig for turning the outer circle of the stepped shaft and radial drilling according to the present invention will be described in detail as follows.

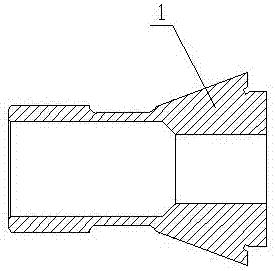

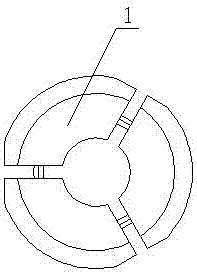

[0025] see Figure 1 to Figure 6 , the fixture of the present invention for turning the outer circle of the step shaft and radially drilling, including a circlip 1 and a fixture body 2, wherein: the fixture body 2 is nested inside the circlip 1, and the fixture body 2 is connected by a connecting body 3 The fixture petal body 4, the installation groove 5 is formed between the fixture petal bodies 4, the fixture petal body 4 is connected with the positioning block 7, the front part of the positioning block 7 is provided with an end face cavity 6, and the positioning block 7 is placed outside the end face of the circlip 1 . A stepped shaft positioning surface is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com