Electrode holder

A technology of electric welding tongs and jaws, which is applied in the direction of electrode characteristics, welding rod characteristics, welding equipment, etc., can solve the problems of unstable and unstable welding rod clamping, laborious installation and replacement of welding rods, difficult operation of welders, etc., and achieves compact structure and heat dissipation Good, accurate clamping and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

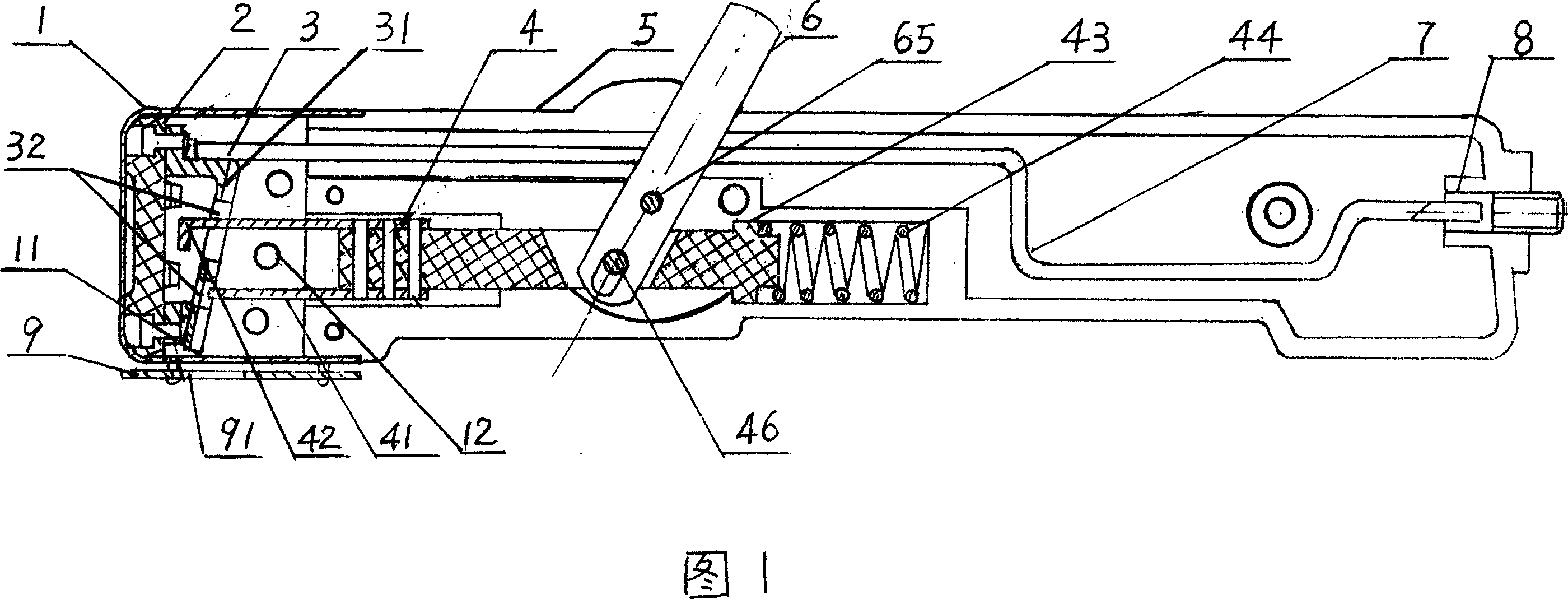

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in the figure, the electric welding tongs includes a jaw and a housing 5. The jaw is made of a jaw frame 3 and a clamping device 4 made of a conductor. Connect, have v-shaped groove 31 in the middle of its front; This v-shaped groove is to deposit welding rod usefulness. The clamping device 4 is composed of a clamping plate 41 whose end face is provided with a v-shaped opening opposite to the v-shaped groove, and a push rod 43 connected thereto and a spring 44 behind it, and the spring force directly passes through the v-shaped The shaped mouth clamping plate 41 acts on the welding rod completely, so that the welding rod is in a stable position. The middle position of the push rod 43 is provided with a push button 6 that is movably connected with the pin shaft 46, and the push button 6 is connected to the housing 5 through a push button shaft 65, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com