Load-bearing connector test specimen clamp for fatigue test machine

A technology of fatigue testing machine and load-bearing joints, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unsatisfactory clamping and accurate detection of multi-directional stretching, and achieve stable clamping, reasonable structural design, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

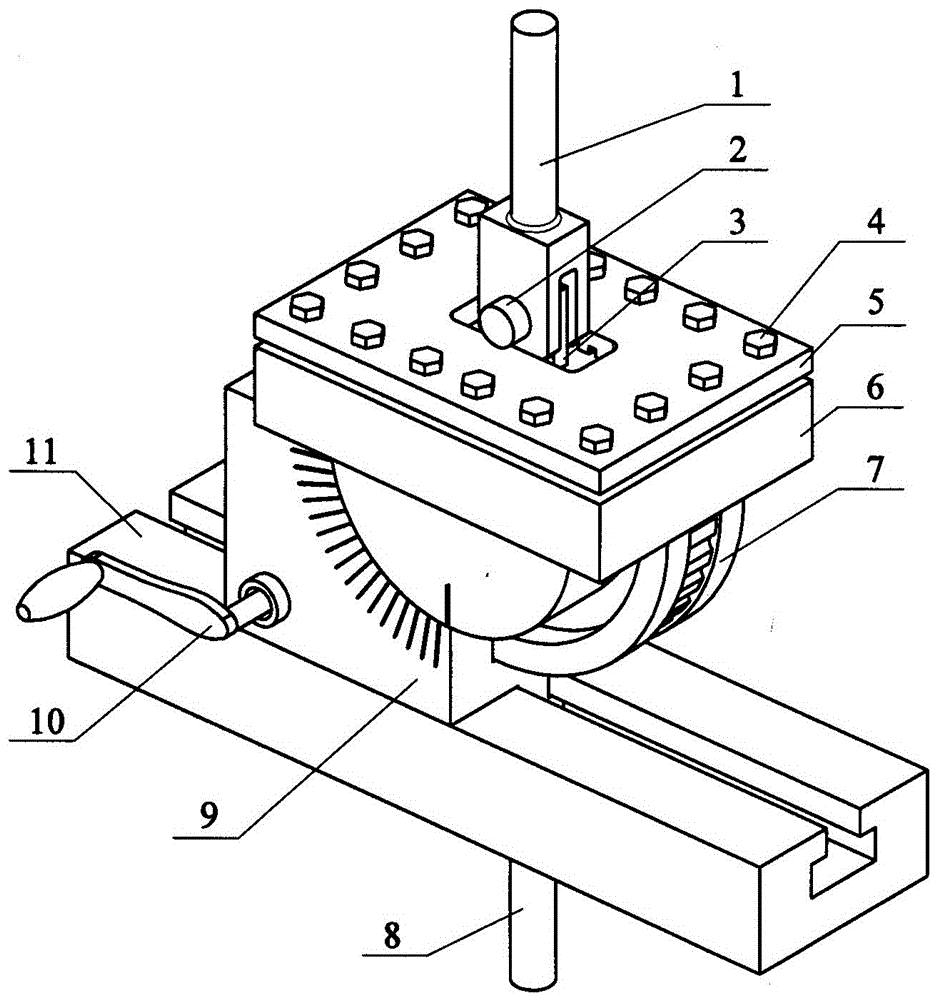

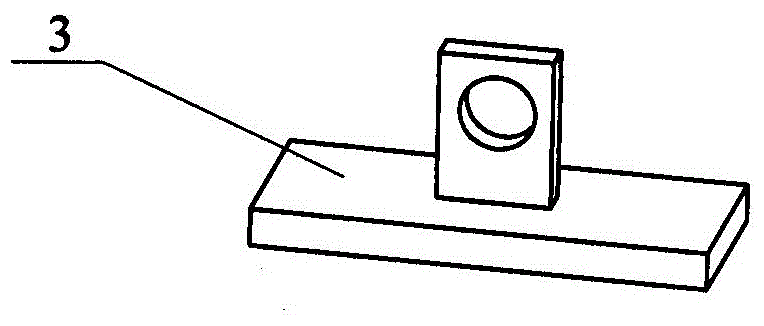

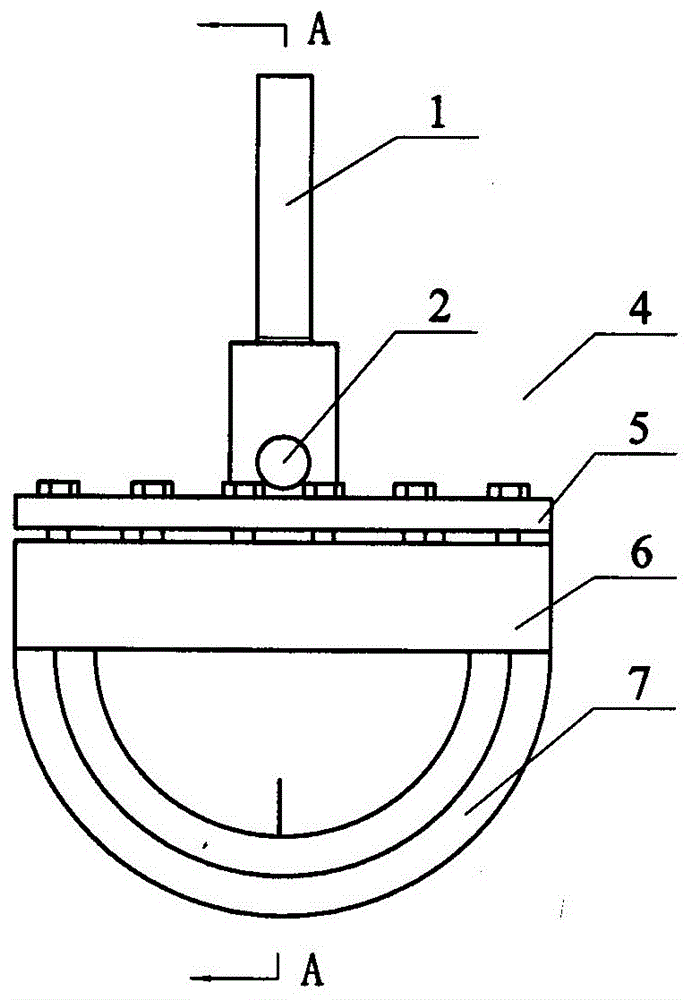

[0022] according to Figure 1-10 The specific structure of the present invention will be described in detail. The load-bearing joint sample fixture for the fatigue testing machine includes a clamping mechanism for clamping the load-bearing joint sample 3 between the upper and lower connecting rods 1 and 8 of the fatigue testing machine, an angle adjustment mechanism and a base 11 and other components. part. Among them, load-bearing joint sample 3 consists of vertical parts and bottoms (such as image 3 shown) constitutes. A stress sensor (not shown in the figure) is attached to the surface of the load-bearing joint sample 3, and the transmission line of the stress sensor is led out through the wire groove on the back of the upper splint 5 and communicated with the computer control equipment.

[0023] The clamping mechanism of clamping load-bearing joint sample 3 is composed of upper and lower splints 5 and 6 with bolt holes around them and fastener bolts 4 and other compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com