Parallel seam welding packaging device

A parallel seam welding and packaging device technology, which is applied in the direction of auxiliary devices, straight seam welding, welding equipment, etc., can solve the problems of low production efficiency, high material cost, and different dimensions, so as to save costs and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

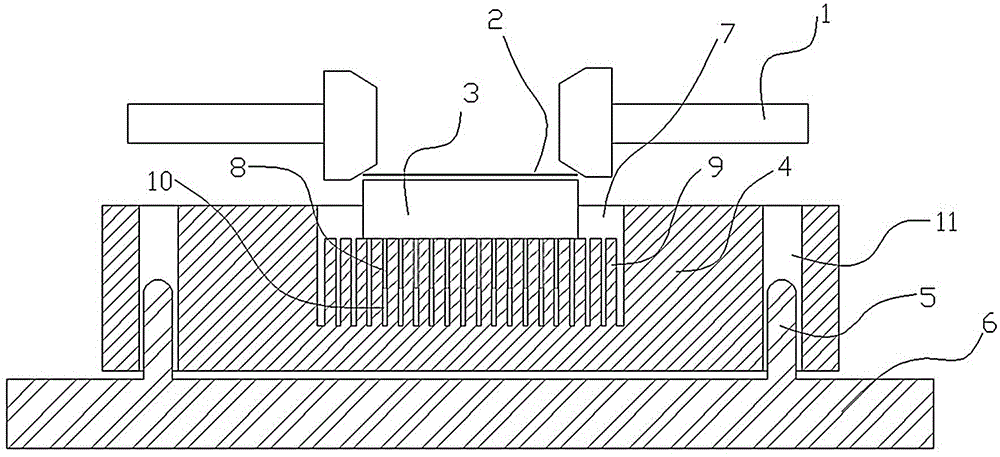

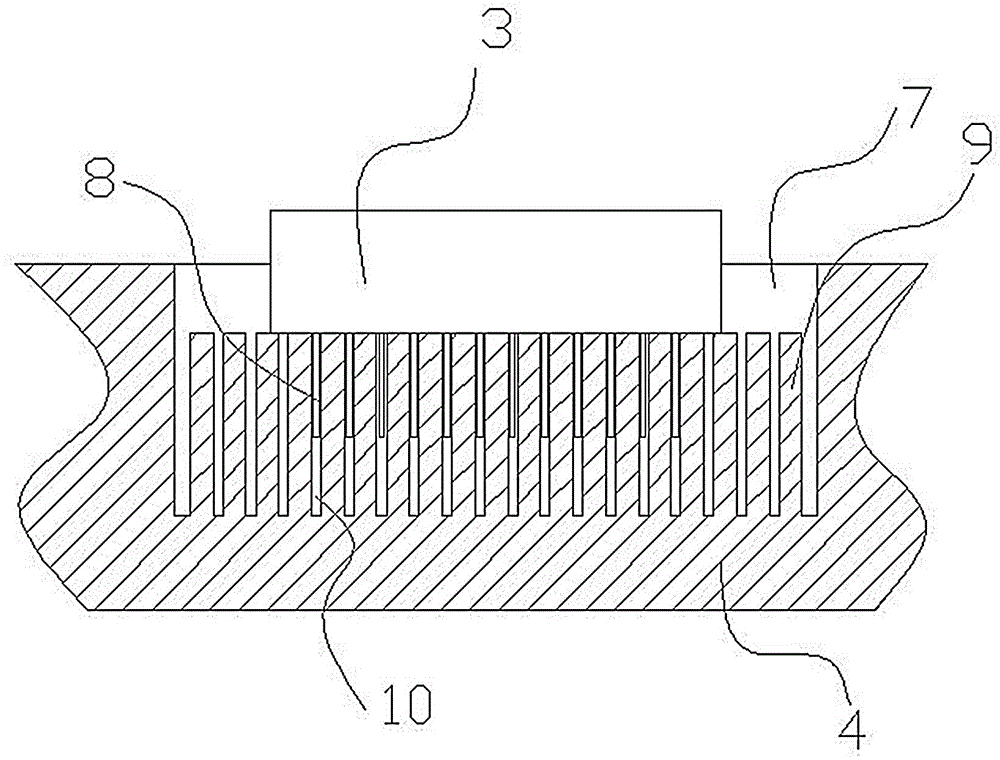

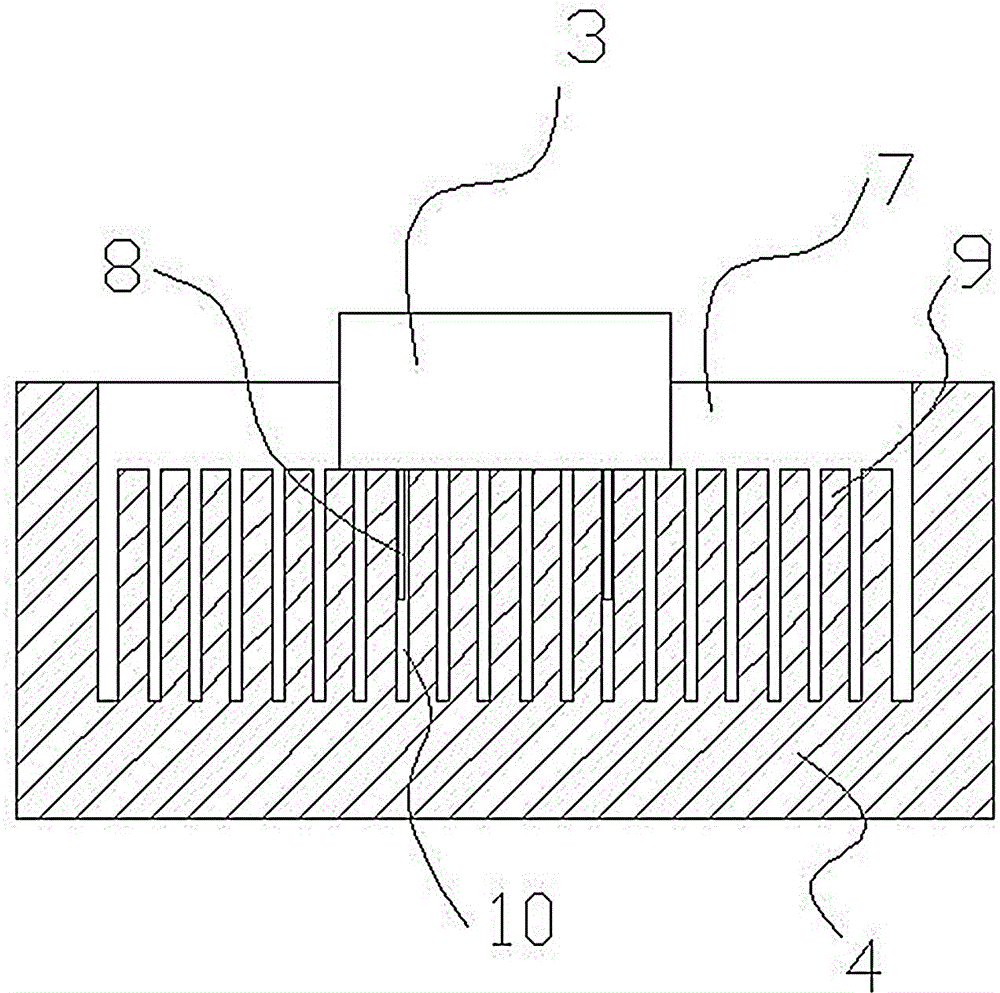

[0016] Such as figure 1 As shown, the present invention provides a parallel seam welding packaging device, including a base 4 arranged on a parallel seam welding receiving platform 6, a positioning hole 11 is provided on the base 4, and the base is realized through the cooperation of the positioning hole 11 and the positioning pin 5 4 and the positioning of the chip holder 6; the top surface of the base 4 is provided with a square groove 7, and the depth of the square groove 7 is less than the height of the dual in-line metal shell 3 to be clamped; combined figure 2 and image 3 As shown, the square groove 7 is vertically provided with rectangular columns 9 evenly distributed in an array, the number of rectangular columns 9 is an odd number in the horizontal direction, and an even number in the vertical direction, and grooves with the same width are formed between adjacent rectangular columns. 10. The groove 10 is matched with the pin 8 of the metal shell, and the rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com