Laser marking method of coil spring

A laser marking method and helical spring technology, which are applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of not being able to see the logo clearly, low efficiency, and not being environmentally friendly, so as to achieve not easy to fall off, improve efficiency, The effect of neat and standardized color code

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

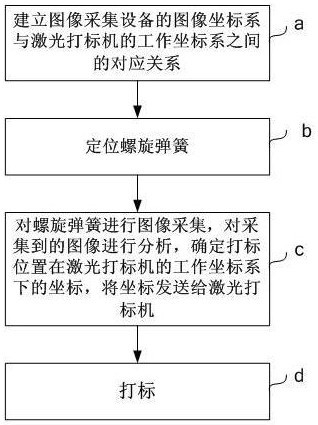

[0016] Please refer to figure 1 . A laser marking method for a helical spring according to an embodiment of the present invention comprises the following steps;

[0017] a. Through calibration, establish the corresponding relationship between the image coordinate system of the image acquisition device and the working coordinate system of the laser marking machine;

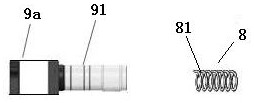

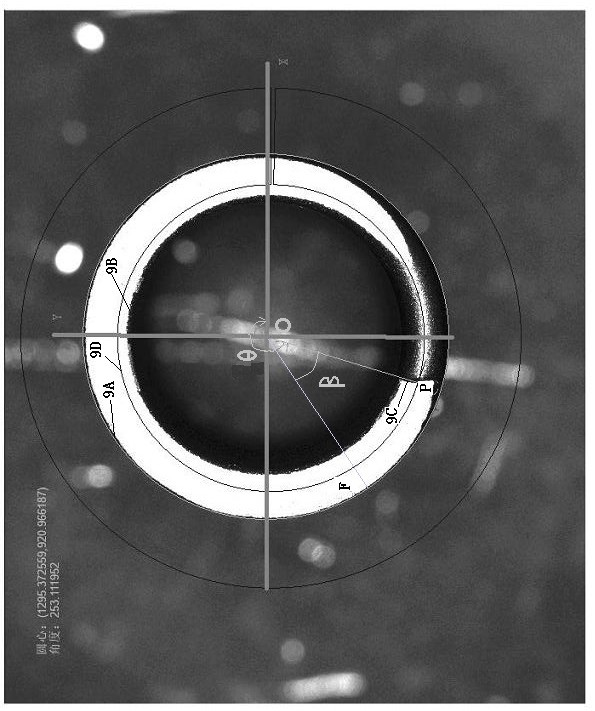

[0018] b. Positioning the helical spring. The end coil of the helical spring to be marked is facing the lens of the image acquisition device; in a specific embodiment, the helical spring can be positioned at a predetermined position by a positioning tool. The positioning datum of all coil springs to be marked is the same. figure 2 A schematic diagram showing the positional relationship between the image acquisition device and the coil spring, from figure 2 It can be seen that the lens 91 of the image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com