Motion control method of robot in oscillatory arc welding of marine T-shaped sections

A technology of motion control and robotics, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of closed core technology, high price, and closed interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0061] At present, my country's ship welding is basically a manual welding method dominated by workers, with low welding efficiency and safety; in addition, due to the particularity of ship welding profiles, it is difficult for existing robot welding technology to be promoted and applied in ship welding .

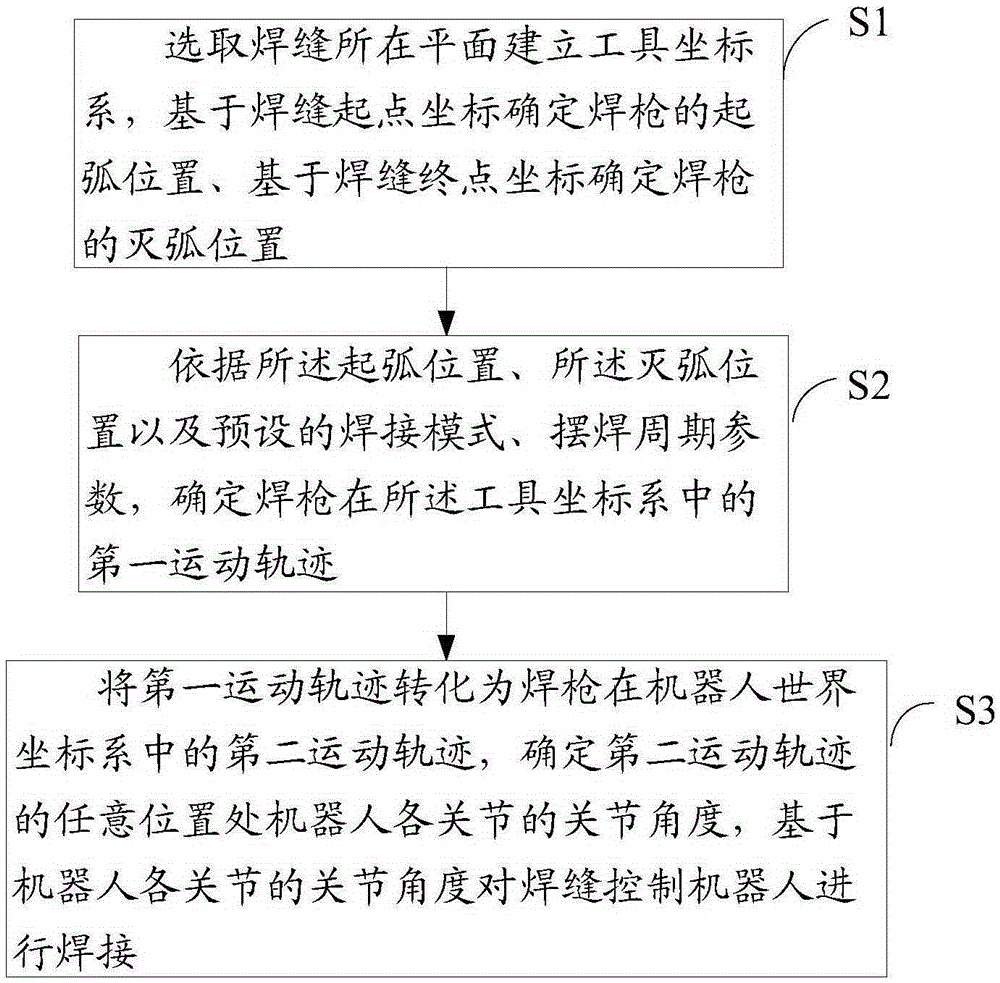

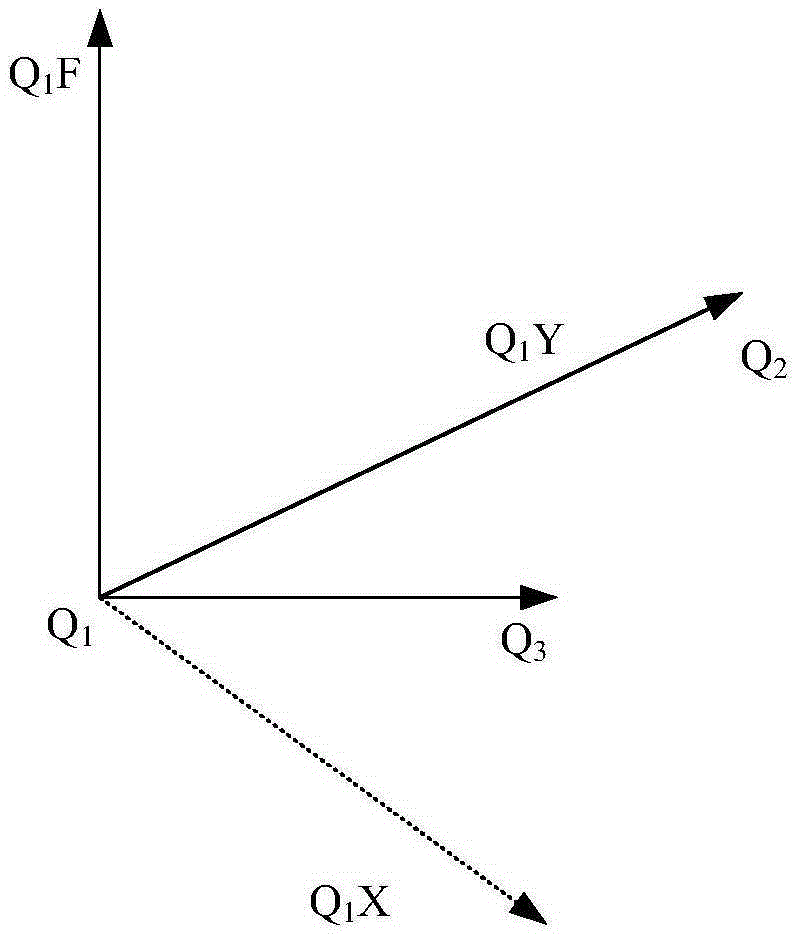

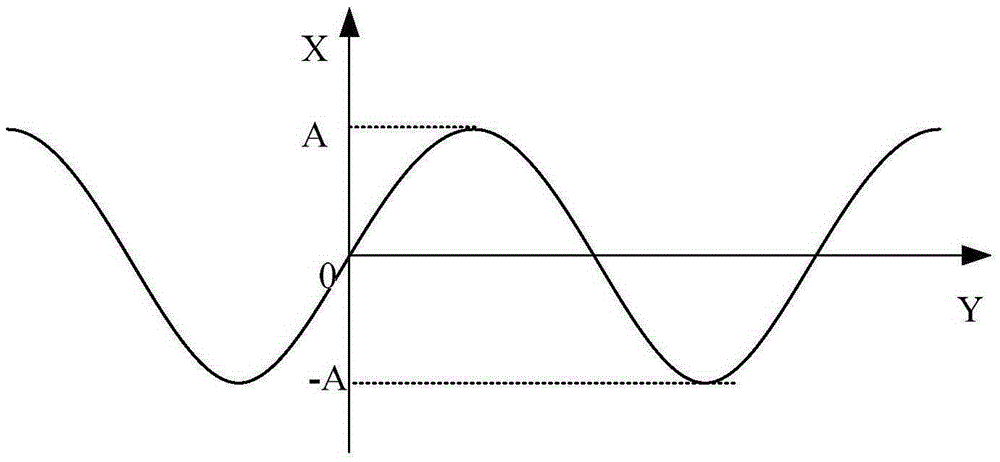

[0062] In order to solve the problems in the prior art, the present invention provides a motion control method for robotic swing arc welding of ship T-sections, by selecting the plane where the weld seam is located to establish a tool coordinate system to determine the first position of the welding torch in the tool coordinate system The motion trajectory is to convert the first motion traject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com