Automatic corrugated pipe welding equipment for transformer and welding method thereof

An automatic welding and corrugated tube technology, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problem that it is difficult to meet the real-time and precision requirements of the automatic welding process, the image processing process is cumbersome, and the automatic welding of bellows for transformers is not easy. Too applicable and other issues, to achieve the effect of friendly operation interface, rich functions, and real-time calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

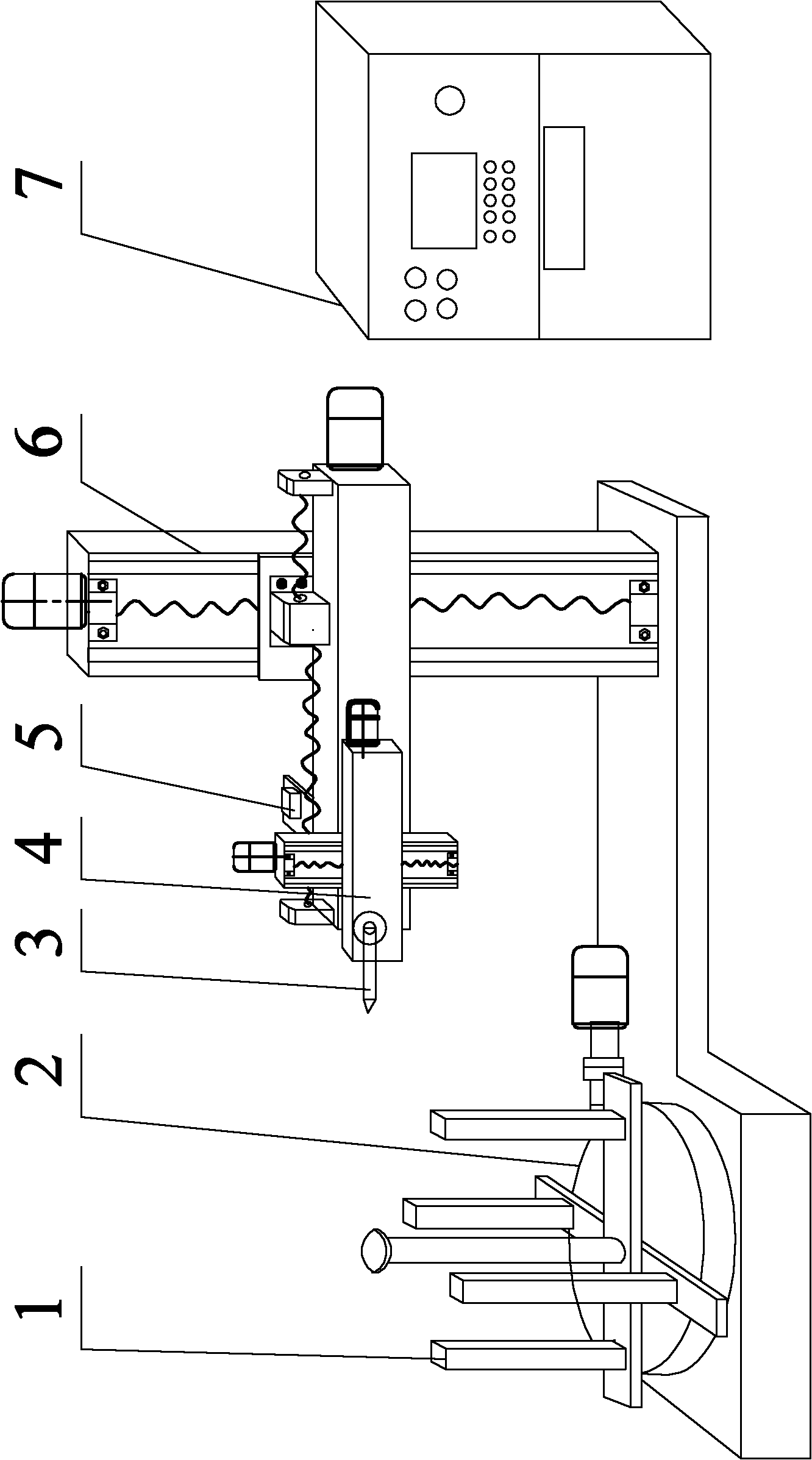

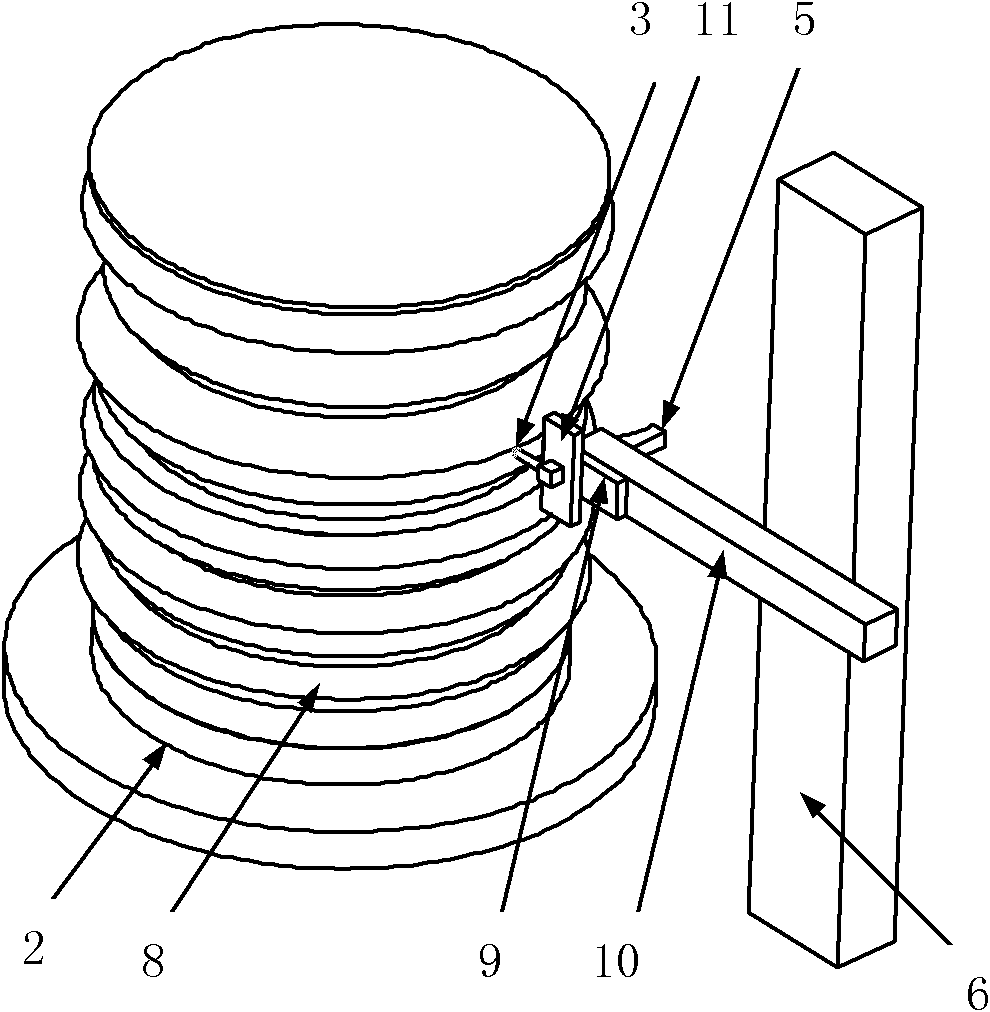

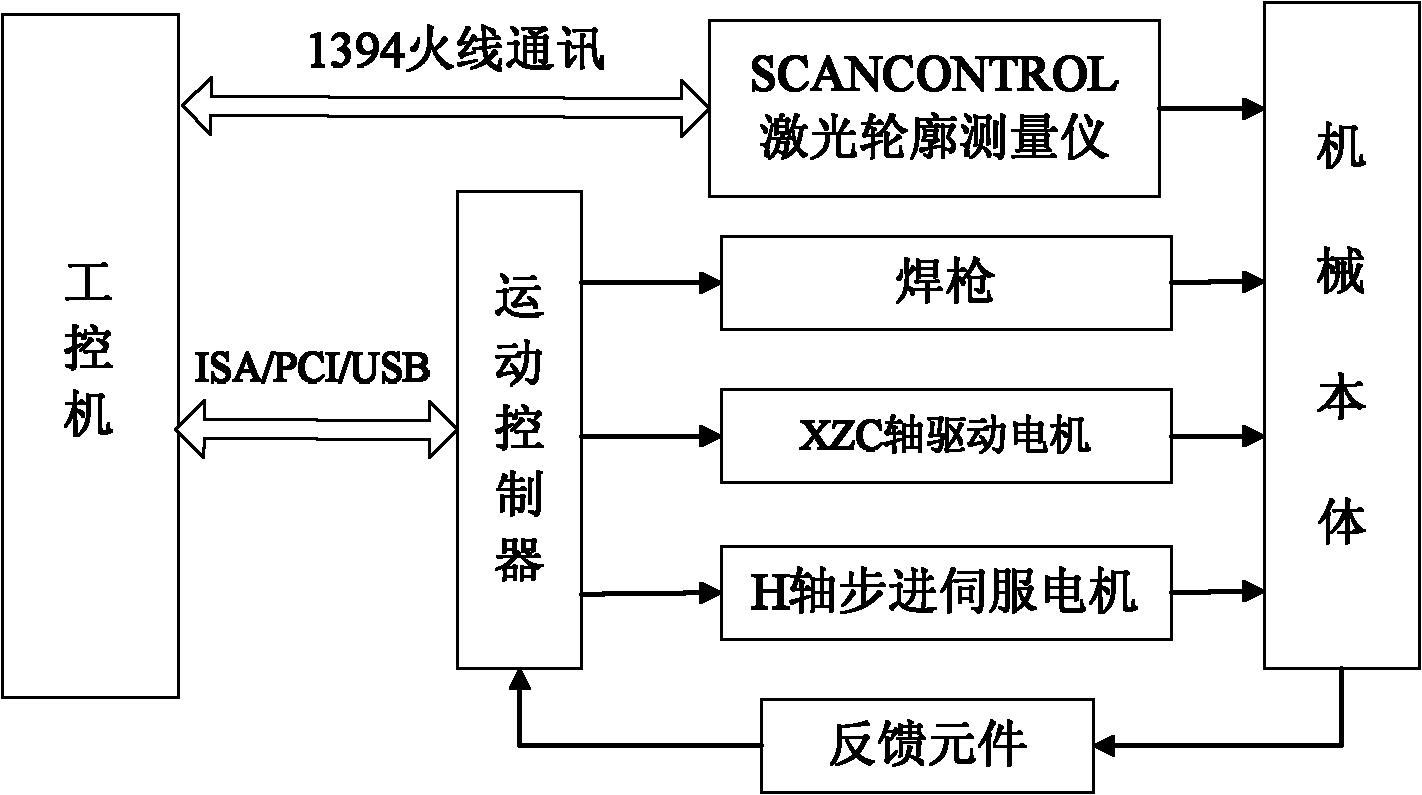

[0036] Embodiment 1: For corrugated pipes of different specifications, the welding torch used as the welding device must have 5 degrees of freedom to meet the requirements of the working position. Therefore, if figure 1 As shown, the present invention includes a rotary table 2, a two-dimensional numerical control platform 4, a laser profile measuring instrument 5, an R-axis 10 and a welding machine tool. The rotary table 2 is fixed on the working table of the machine tool, and one end of the R-axis 10 is slidingly installed on On the bed 6 of the welding machine tool, a laser profile measuring instrument 5 and a two-dimensional numerical control platform 4 sliding along the R axis 10 are respectively installed on both sides of the other end, and a welding torch 3 is slidably connected to the two-dimensional numerical control platform. The laser of the instrument 5 is parallel to the axis of the welding torch 3, the rotary table 2, the two-dimensional numerical control platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com