Automatic bead welding equipment of saddle-shaped pipe joint surface with conical table and welding method thereof

An automatic surfacing, saddle-shaped technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve problems such as uneven spacing of weld beads, uneven surfacing surface, and increased grinding workload. The effect of improving the utilization rate of welding materials, less welding joints, and reducing the amount of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

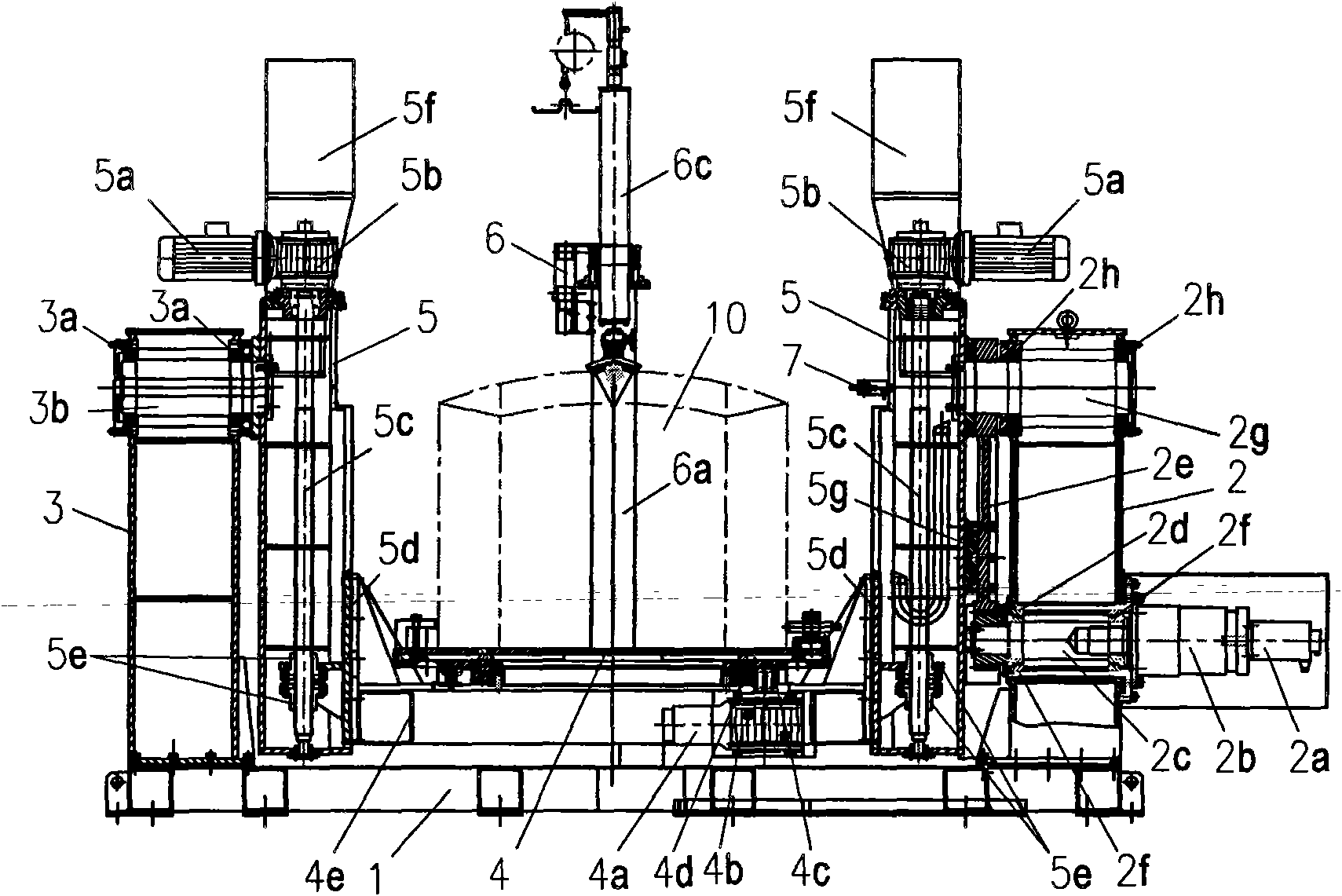

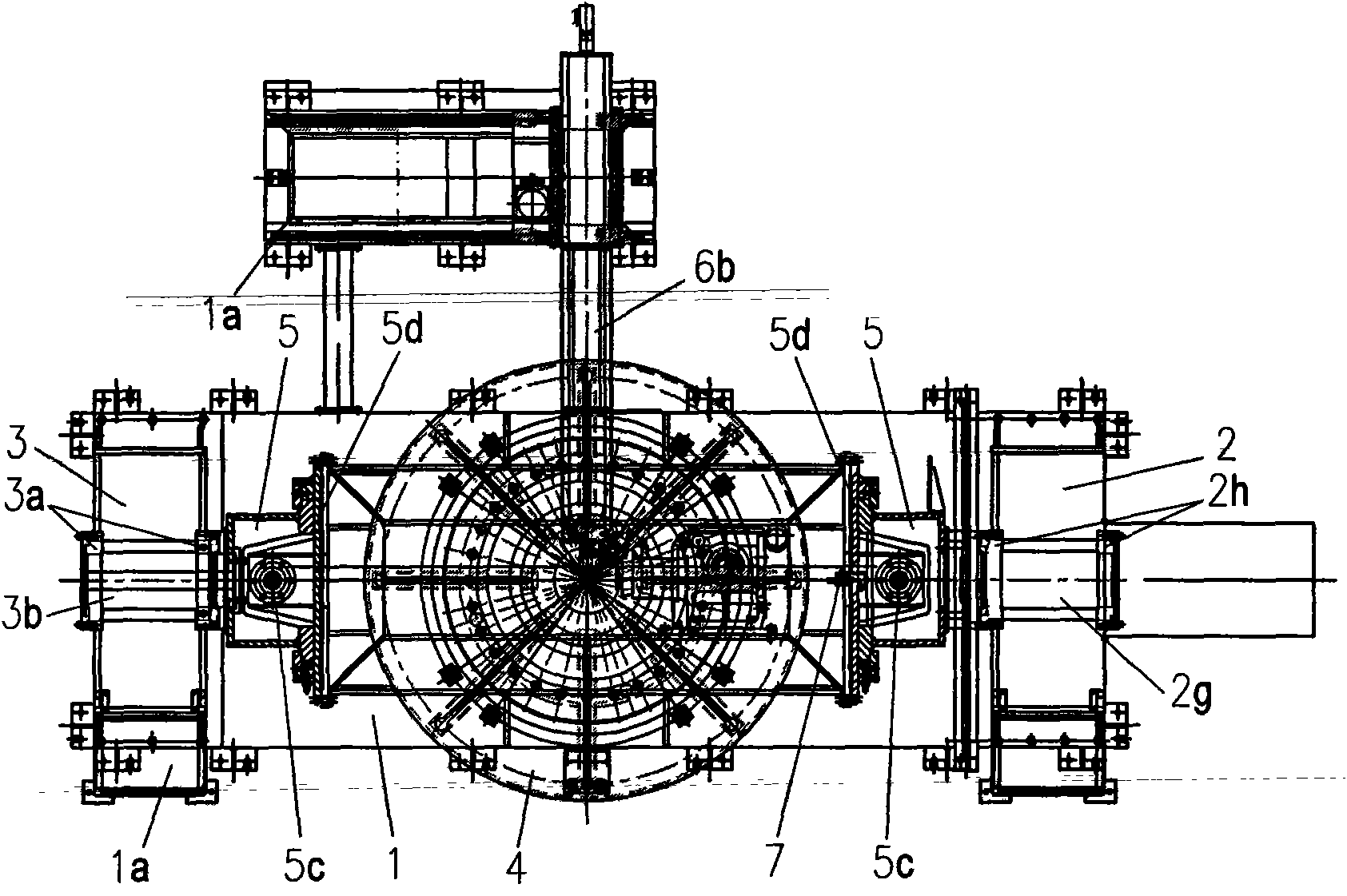

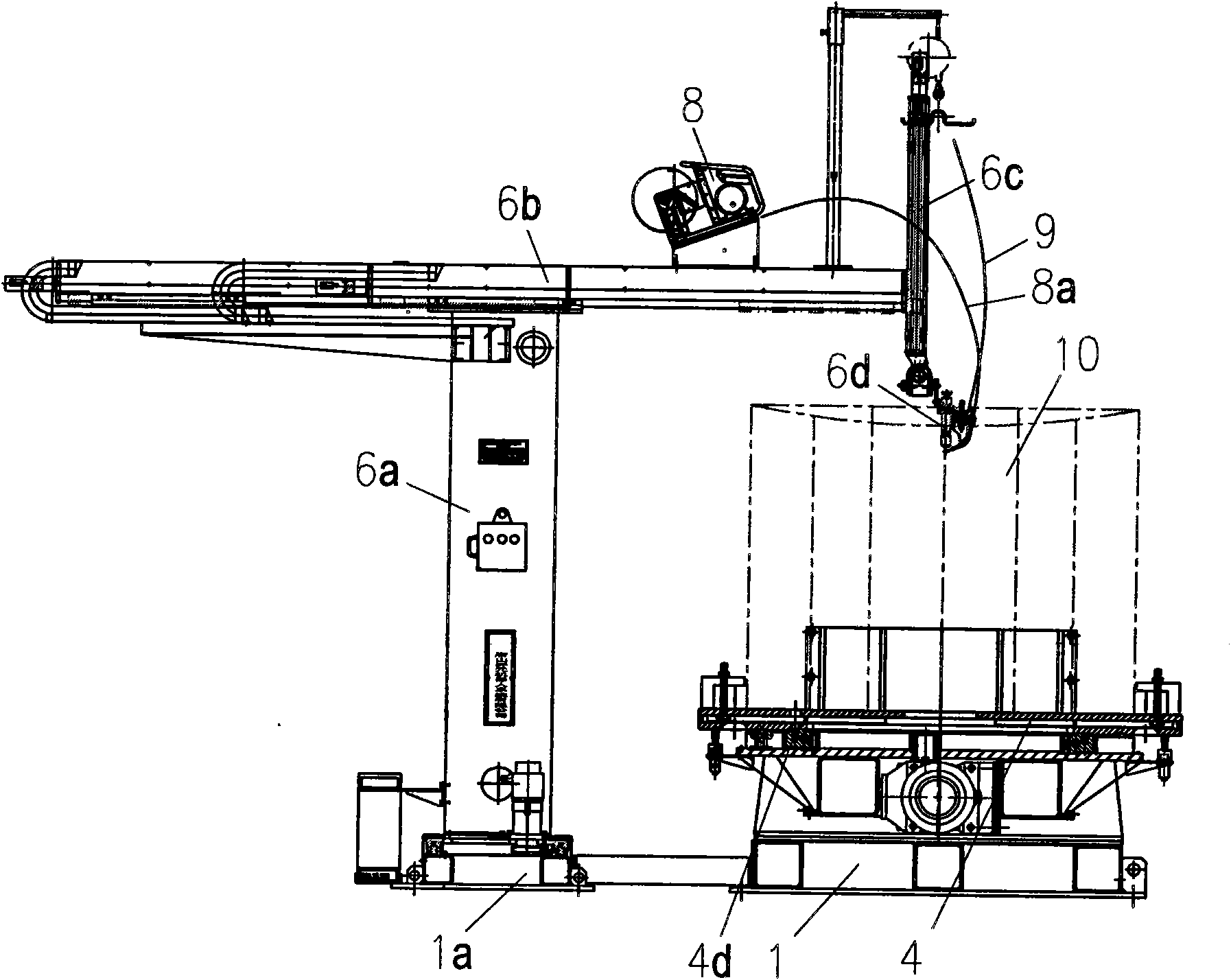

[0036] figure 1 , 2 , 3, 4 show a structural diagram of a saddle-shaped pipe joint welding equipment with a conical frustum. In the figure, the automatic welding equipment includes a station adjustment device for lifting, rotating and tilting the workpiece, an automatic welding torch manipulator 6, a laser positioner 7 and an electrical control device. The station adjustment device is integrated and installed on a base 1, and the automatic welding torch The manipulator 6 is installed on a small base 1a. When working, the electrical control device controls the dynamic cooperation between the station adjustment device and the automatic welding torch manipulator according to the preset operation instructions to complete the intersecting line weld of the saddle-shaped pipe joint with conical truncated welding. The following mainly introduces the worktable rotation mechanism, worktable lifting mechanism and worktable tilting mechanism included in the station adjustment device.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com