Welding device for battery module

A battery module and welding device technology, which is applied to battery pack components, auxiliary devices, tin feeding devices, etc., can solve the problems of desoldering, small solder joint area, false soldering and false soldering rate, etc., and improve the anti-corrosion ability , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

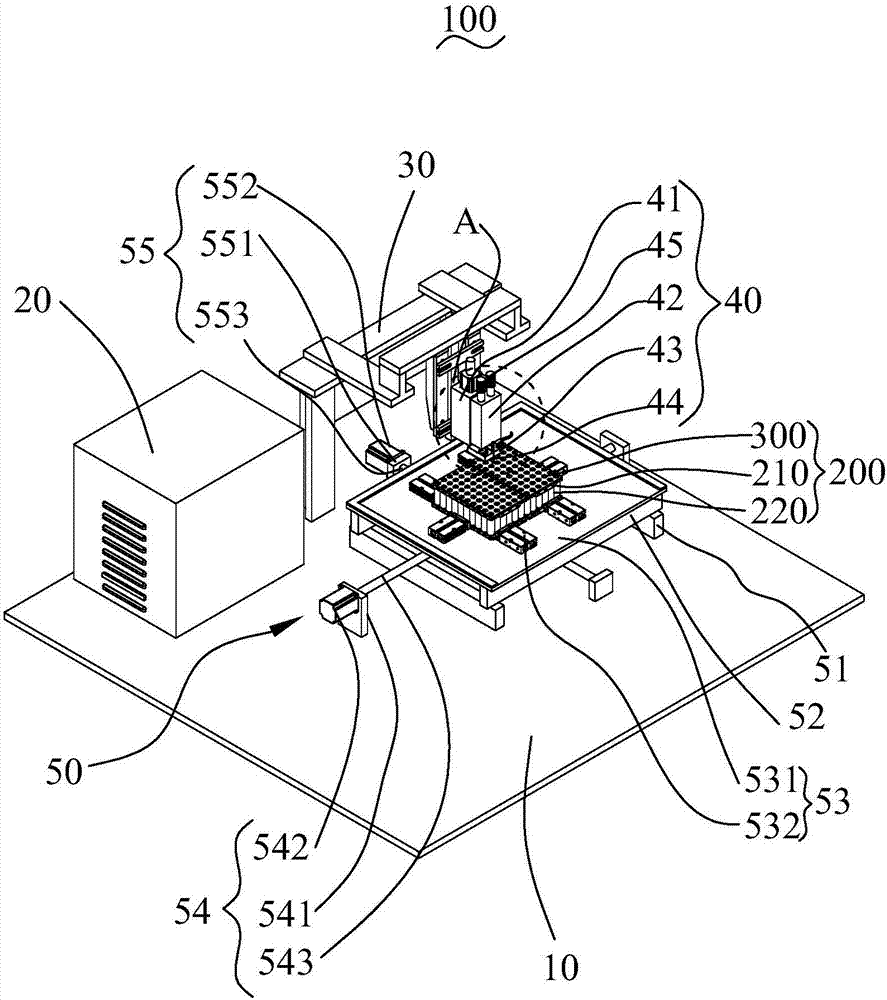

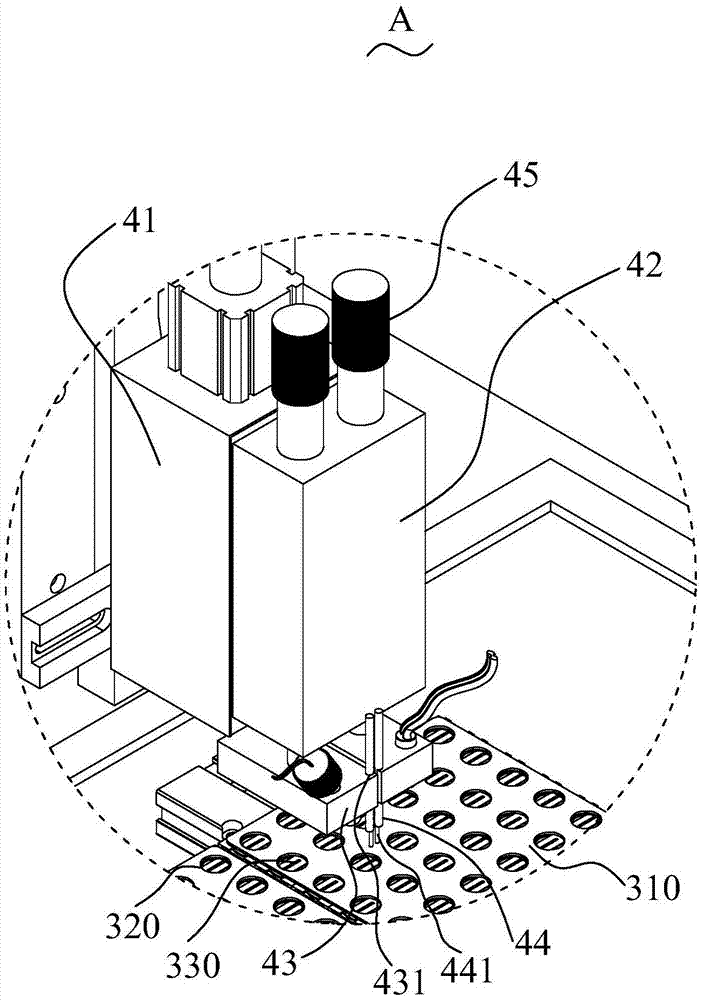

[0011] Please also refer to Figure 1-2 , which is a perspective view of the battery module welding device 100 provided by the present invention. The battery module welding device 100 is used for welding the battery module 200 . Wherein, the battery module 200 includes a pair of brackets 210 arranged at intervals, a number of single cells 220 fixed at both ends of the two brackets 210, and a plurality of single cells 220 respectively fixed on the two brackets 210 and close to the plurality of cells. The bus plate 300 on the end face of the bulk b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com