Oil tank shell inner rib plate welding equipment

A technology for welding equipment and shells, which is applied in the field of welding equipment for inner ribs of oil tank shells, and can solve problems such as low welding efficiency, large volume, and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

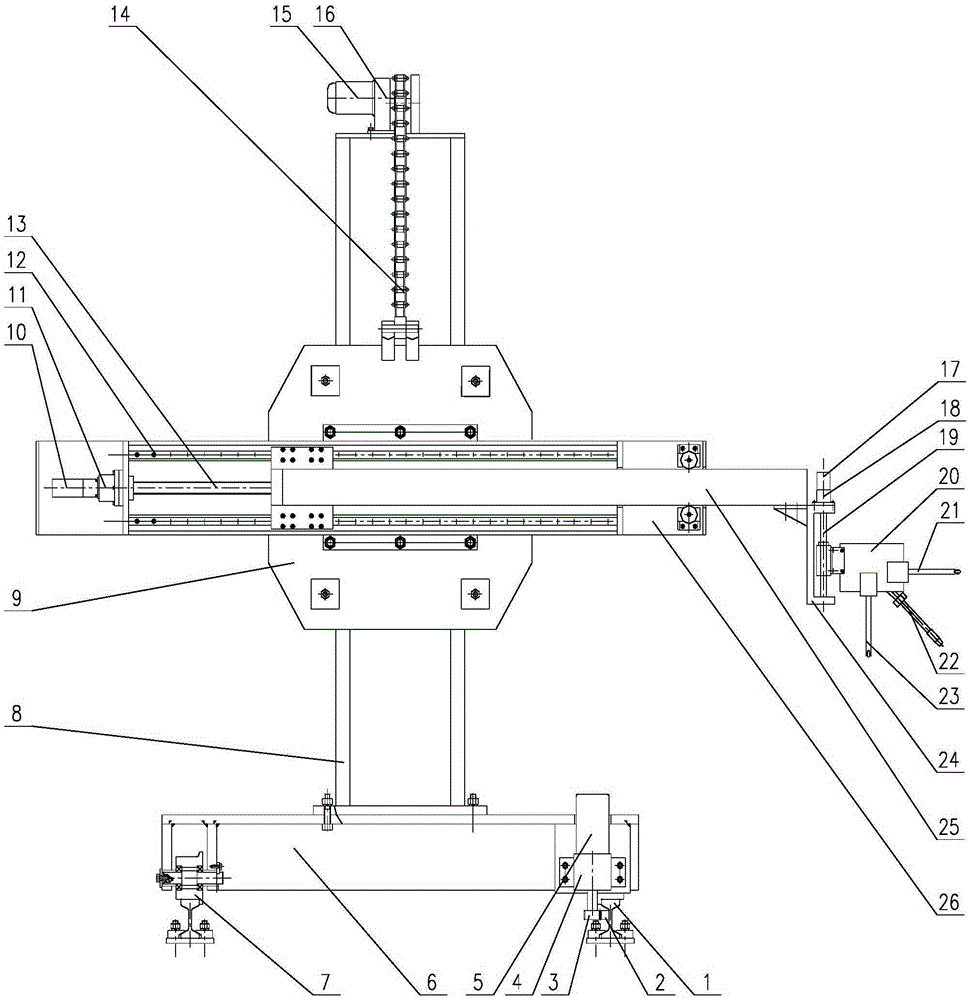

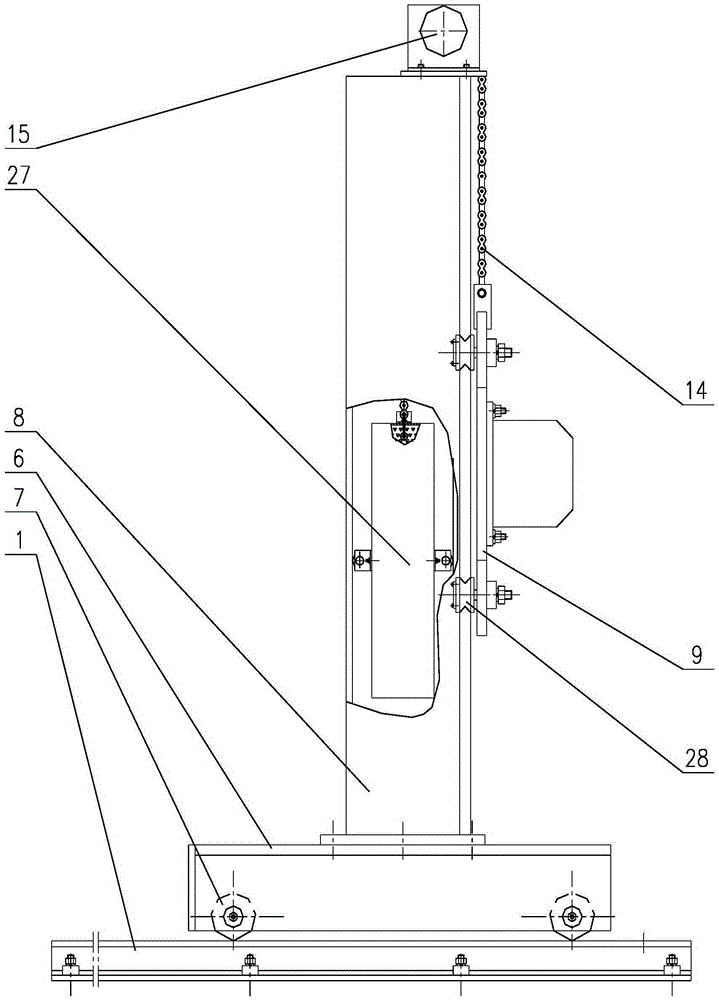

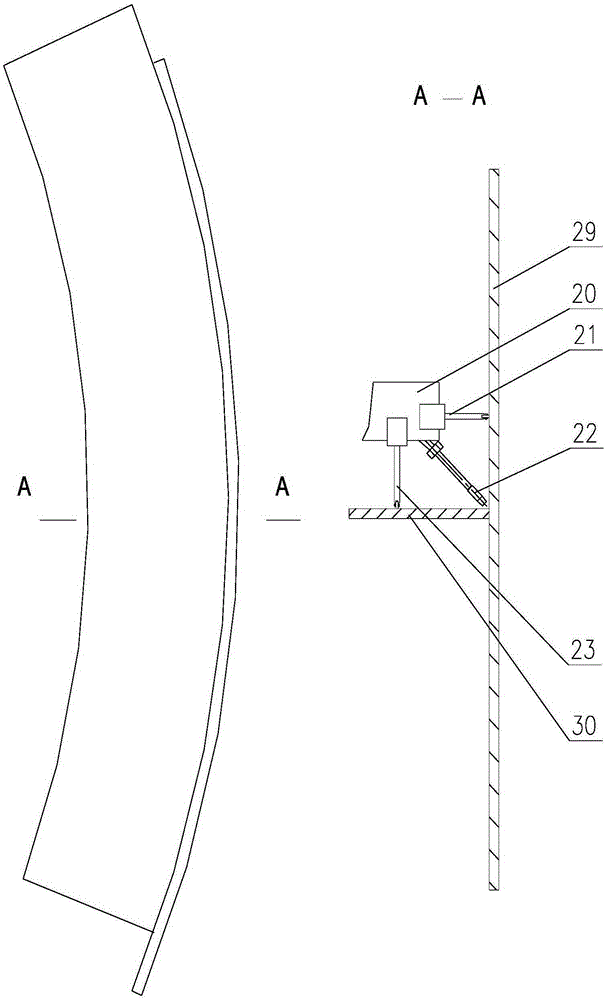

[0010] A kind of welding equipment for the inner rib plate of the oil tank shell, which is composed of a longitudinal guide rail, a base, a column, a slide plate, a beam, a telescopic arm and a welding mechanism, and is characterized in that: the longitudinal guide rail has a steel rail 1 and a rack 2 structure , the base 6 has a longitudinal drive motor 5, a longitudinal reducer 4, a gear 3 and a roller 7 structure, and the column 8 has a lifting guide rail, a lifting motor 15, a lifting reducer 16, a chain 14 and a counterweight 27 structure, the slide plate has a lifting guide wheel 28 and a frame plate 9 structure, and the beam 26 has a structure of a horizontal servo motor 10, a horizontal reducer 11, a horizontal linear guide rail 12 and a horizontal ball screw 13, and the base 6 A longitudinal drive motor 5 and a longitudinal reducer 6 are installed on the top to drive the gear 3 to rotate, so that the base 6 moves along the longitudinal guide rail, the column 8 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com